Piston type industrial pump parallel using system and method

An industrial pump and piston technology, applied in the direction of variable displacement pump components, pumps, pump devices, etc., can solve the problems of large equipment installation capacity and high equipment investment costs, reduce equipment investment costs, eliminate equipment idle rate, and ensure The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

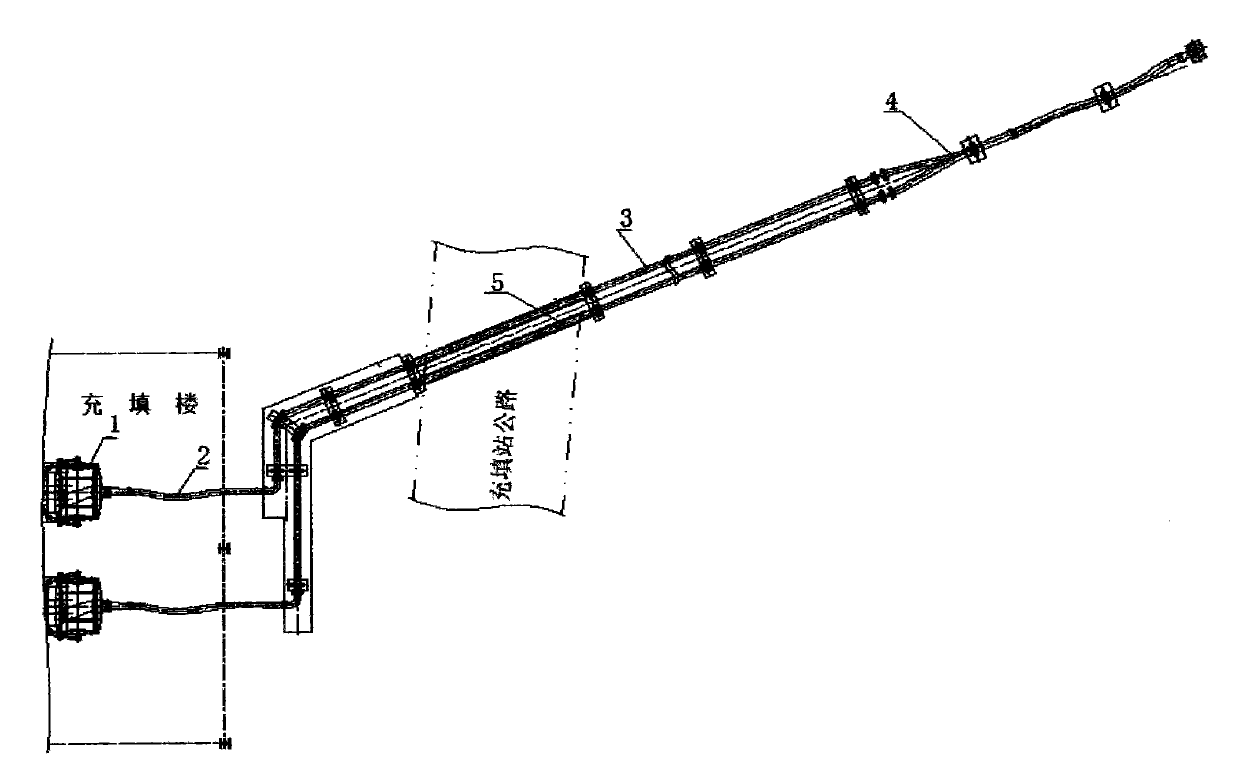

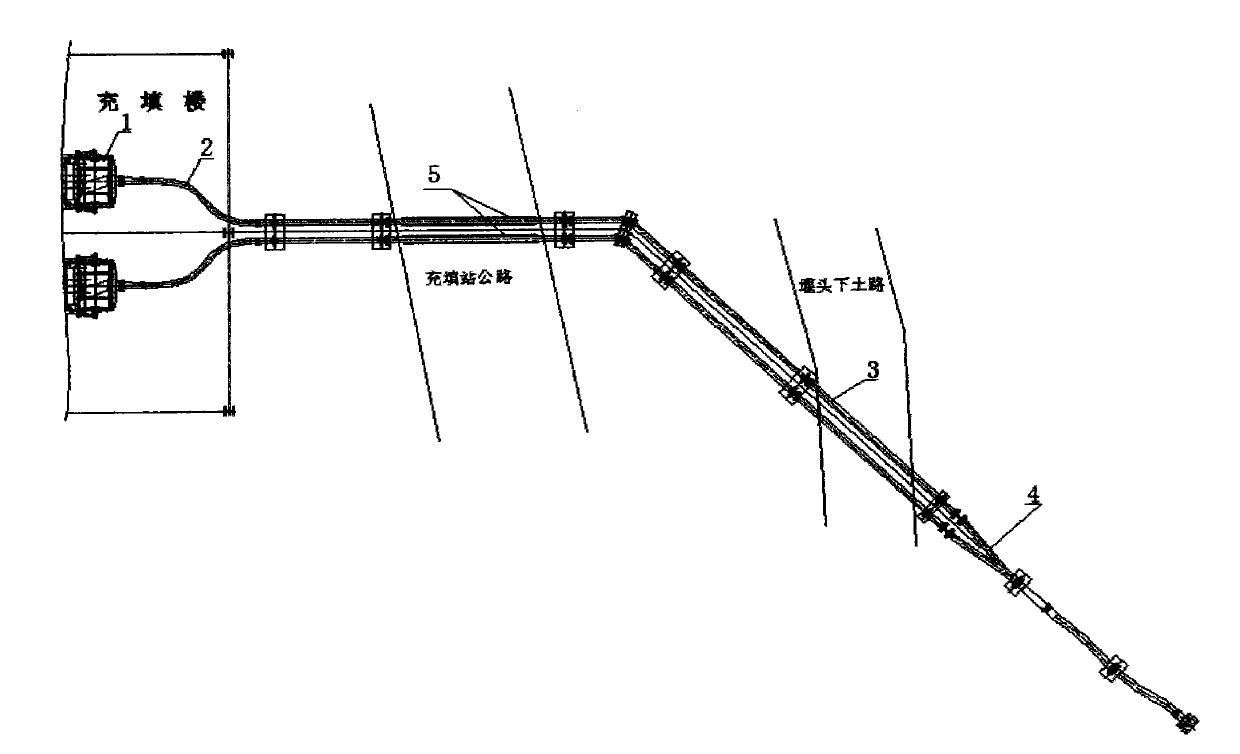

[0012] like figure 1 , 2 As shown, a system for using a piston-type industrial pump of the present invention includes two parallel-connected piston-type industrial pumps 1, each outlet of the piston-type industrial pump 1 is connected to a hose 2 and a hard pipe 3 in sequence, and the two trips The hard pipe 3 is connected to a converging tee 4, which is merged into a pipeline.

[0013] A passage pipe 5 may also be provided between the flexible pipe 2 and the hard pipe 3 . The piston type industrial pump 1 is installed in parallel in the filling building.

[0014] A pumping method of a piston type industrial pump using system of the present invention:

[0015] The parallel state of two piston industrial pumps 1 is the actual arrangement in the paste filling project of Jizhong Energy Fengfeng Group Yangdong Mine, Xinsan Mine, and Dali Mining Co., Ltd. The two pumps (HGBS100 piston industrial pumps , the maximum theoretical displacement is 97m 3 / h, normal pumping pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com