Method and device for producing mono-nitro toluence by adiabatic nitration through self-mixing tubular reactor

A tubular reactor and mononitrotoluene technology, applied in the preparation of nitro compounds, organic chemistry, etc., can solve the problems of large floor area, low production efficiency, high investment cost, etc., and achieve reduced floor space and compact equipment , Reduce energy consumption and equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

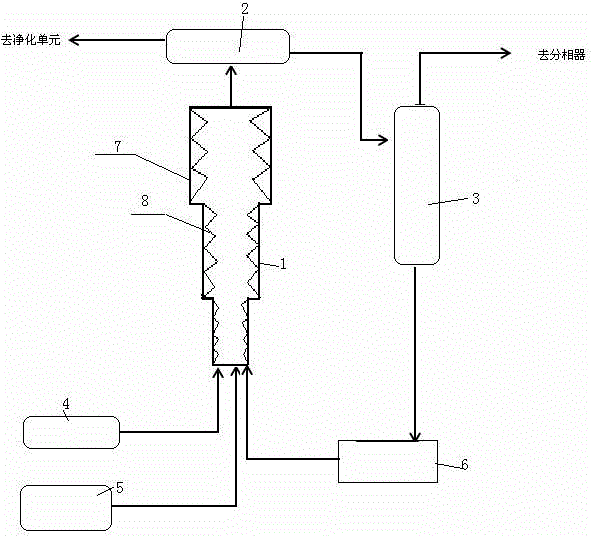

[0016] Embodiment 1: After a certain amount of sulfuric acid with a mass concentration of 95% circulates in the system for a certain period of time, toluene and 50% dilute nitric acid with a mass concentration are pumped into the self-mixing tubular reactor 1 according to the molar ratio of 1:1.0. Under the disturbance of the corrugated plate 8 of the reactor, the nitrification reaction occurs while the efficient radial circulation mixing is carried out; the heat released by the reaction is absorbed by the sulfuric acid, and the reacted material enters the static phase separator 2, and after phase separation, the organic phase enters Subsequent purification unit purification, the acid phase that has absorbed the reaction heat enters the sulfuric acid concentrator 3, directly flashes the water and the entrained organic phase without inputting steam, and the concentrated sulfuric acid is returned to the reactor for recycling. After testing and analysis, the conversion rate of nit...

Embodiment 2

[0017] Embodiment 2: after the sulfuric acid of a certain amount of mass concentration 98% circulates in the system for a certain period of time, toluene, mass concentration 60% dilute nitric acid are pumped in the self-mixing tubular reactor 1 according to the feeding ratio of initial molar ratio 1.05:1, Under the disturbance of the corrugated plate 8 in the reactor, the material undergoes efficient radial circulation mixing and nitration reaction occurs at the same time; the heat released by the reaction is absorbed by sulfuric acid, and the reacted material enters the static phase separator 2. After phase separation, organic The phase enters the subsequent purification unit for purification, and the acid phase that has absorbed the reaction heat enters the sulfuric acid concentrator 3 to directly flash out the water and the entrained organic phase without inputting steam, and the concentrated sulfuric acid is returned to the reactor for recycling. After testing and analysis,...

Embodiment 3

[0018] Embodiment 3: After a certain amount of sulfuric acid with a mass concentration of 98% circulates in the system for a certain period of time, toluene and 55% dilute nitric acid with a mass concentration are pumped into the self-mixing tubular reactor 1 according to the initial molar ratio of 1:1.05. Under the disturbance of the corrugated plate 8 in the reactor, the material undergoes efficient radial circulation mixing and nitration reaction occurs at the same time; the heat released by the reaction is absorbed by sulfuric acid, and the reacted material enters the static phase separator 2. After phase separation, organic The phase enters the subsequent purification unit for purification, and the acid phase that has absorbed the reaction heat enters the sulfuric acid concentrator 3 to directly flash out the water and the entrained organic phase without inputting steam, and the concentrated sulfuric acid is returned to the reactor for recycling. After testing and analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com