Long-acting insect prevention and mosquito repelling PP (Polypropylene) non-woven fabric and preparation method thereof

A non-woven fabric and mosquito repellent technology, which is applied in the fields of non-woven fabrics, rayon manufacturing, textiles and paper making, and can solve the problems of reduced insect repellent and mosquito repellent effects, poor washability of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1 Preparation of insect-proof and mosquito-repellent masterbatch

[0098] Using polypropylene as the carrier of the masterbatch, according to the formula shown in Table 1, prepare the insect repellent masterbatch:

[0099] Table 1 Formula of insect-proof and mosquito-repellent masterbatch

[0100] sample

Embodiment 2

[0101] Example 2 Preparation of long-acting insect repellent and mosquito repellent PP spunbonded nonwoven fabric

[0102] The insect-proof and mosquito-repellent masterbatch sample that embodiment 1 obtains is made into non-woven fabric through the following spun-bonding steps:

[0103] Feeding→melting→filtering→spinning→cooling→drawing→laying→consolidation→winding.

[0104] 1. Feeding:

[0105] Raw material: polypropylene, the addition amount is 95-99.9% (wt)

[0106] Insect-proof and mosquito-repellent master grain (prepared in embodiment 1) injection amount 0.1-5% (wt)

[0107] Equipment: suction system, injection machine

[0108] Process description: Through the suction system and injection machine, according to the above-mentioned metering ratio of feeding, the polypropylene raw material and the insect-repelling and mosquito-repelling masterbatch obtained in Example 1 are sent to the screw extruder for preliminary mixing.

[0109] 2. Melting:

[0110] Equipment: scr...

Embodiment 3

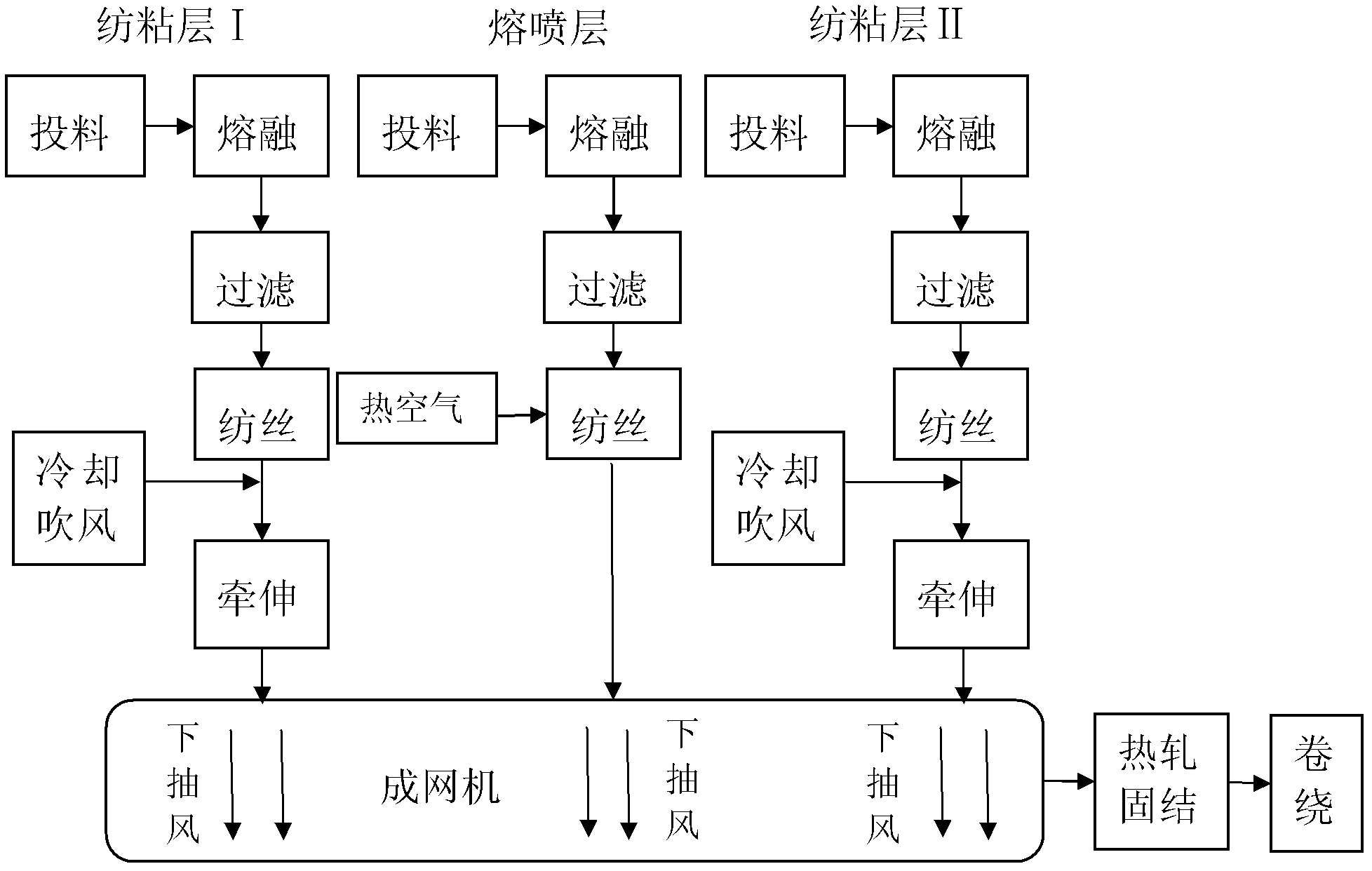

[0142]Example 3 Preparation of long-acting insect-repellent and mosquito-repellent PP spunbond-melt-blown-spunbond non-woven fabric The insect-proof and mosquito-repellent masterbatch sample obtained in Example 1 was made into a non-woven fabric through the following (spunbond-meltblown-spunbond) steps. Spinning:

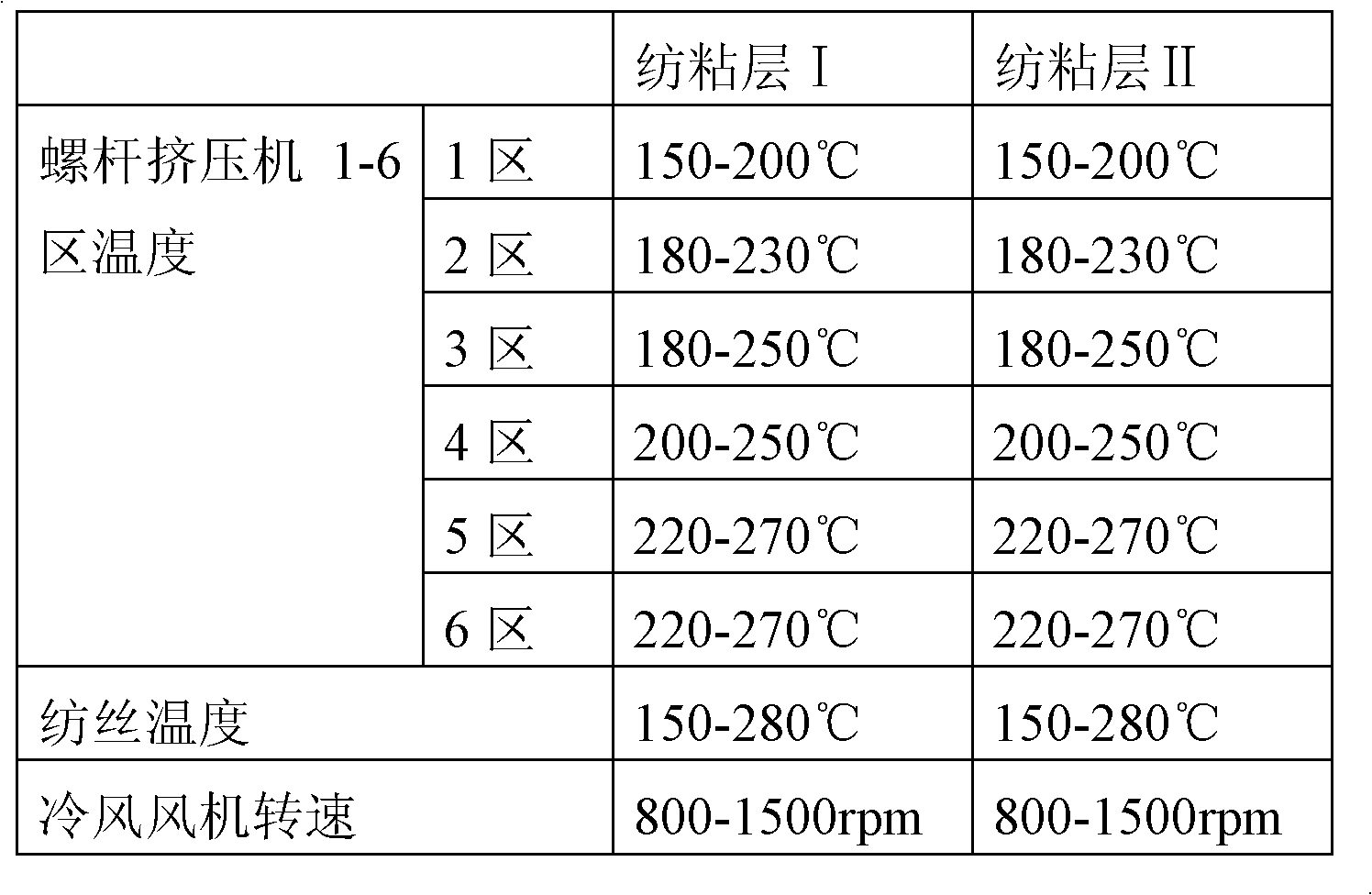

[0143] According to the spinning steps of the spunbond layer in Example 2: feeding→melting→filtering→spinning→cooling→drawing, the process parameters are as follows, see Table 2.

[0144] Table 2 process parameters

[0145]

[0146] Spinning steps of meltblown layer:

[0147] Feeding→melting→filtering→spinning

[0148] 1. Feeding:

[0149] Raw material: polypropylene, the addition amount is 95-99.9% (wt)

[0150] Insect-proof and mosquito-repellent master grain (prepared in embodiment 1) injection amount 0.1-5% (wt)

[0151] Equipment: suction system, injection machine

[0152] Process description: Through the suction system and injection machine, according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com