Integrated-type acid-washing unit

An integrated acid and unit technology, which is applied in the field of steel processing, can solve the problems of increasing the probability of pipeline safety accidents, troublesome acid recovery tank inspection and maintenance, and complicated pipeline laying, so as to simplify the laying of acid transportation pipelines, Eliminate the construction of acid recovery tanks and reduce the effect of acid mist treatment pipelines and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

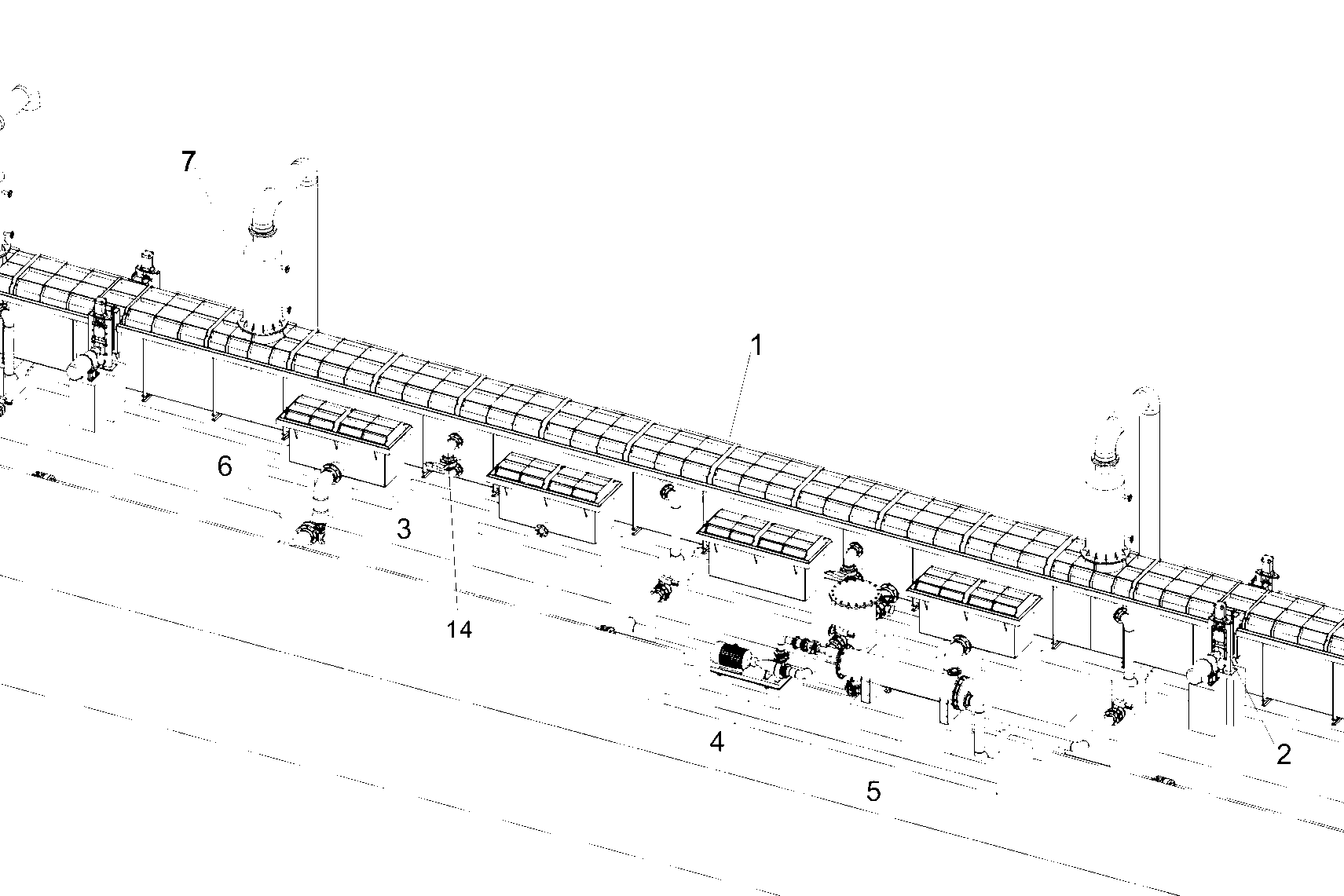

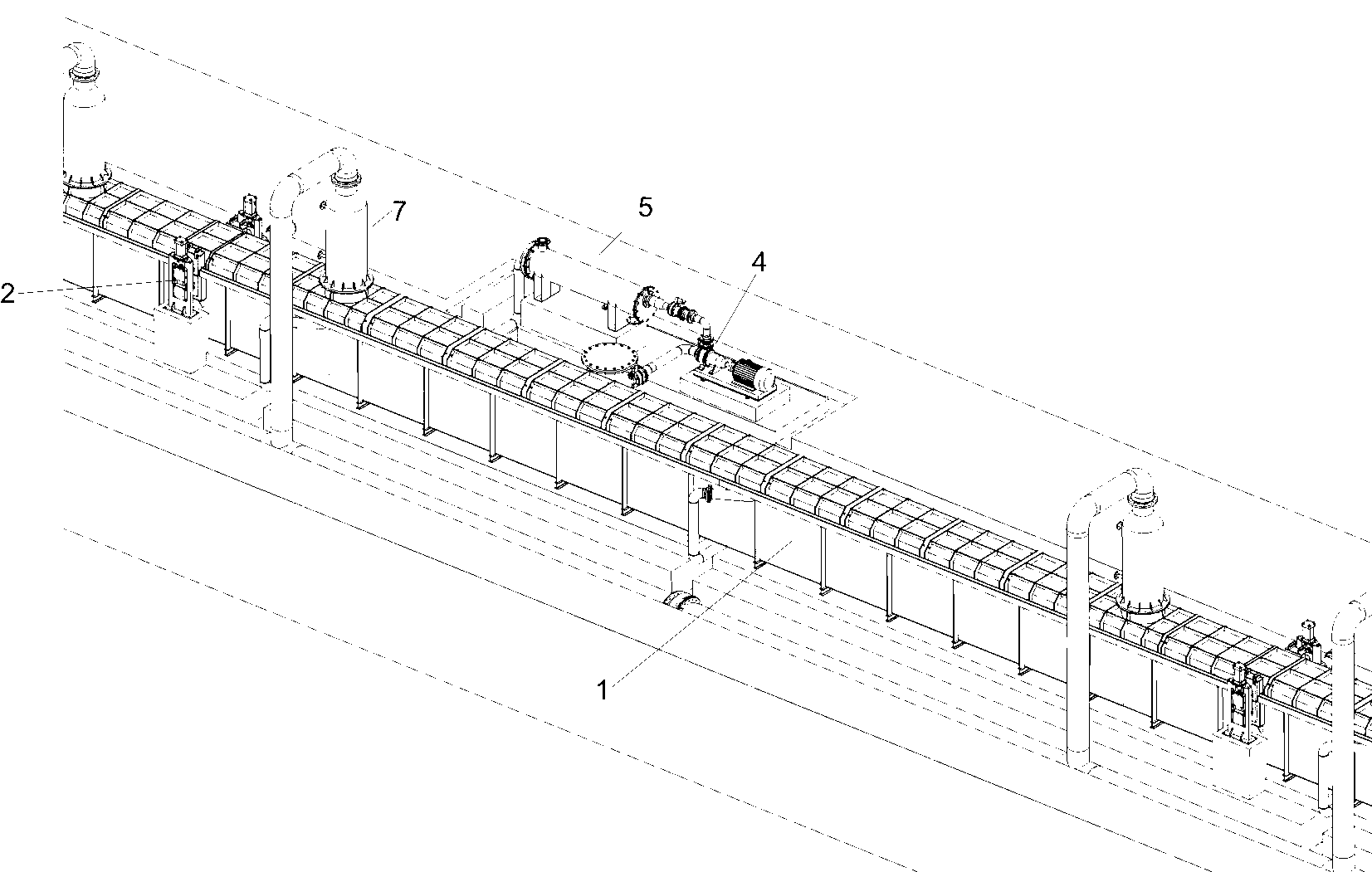

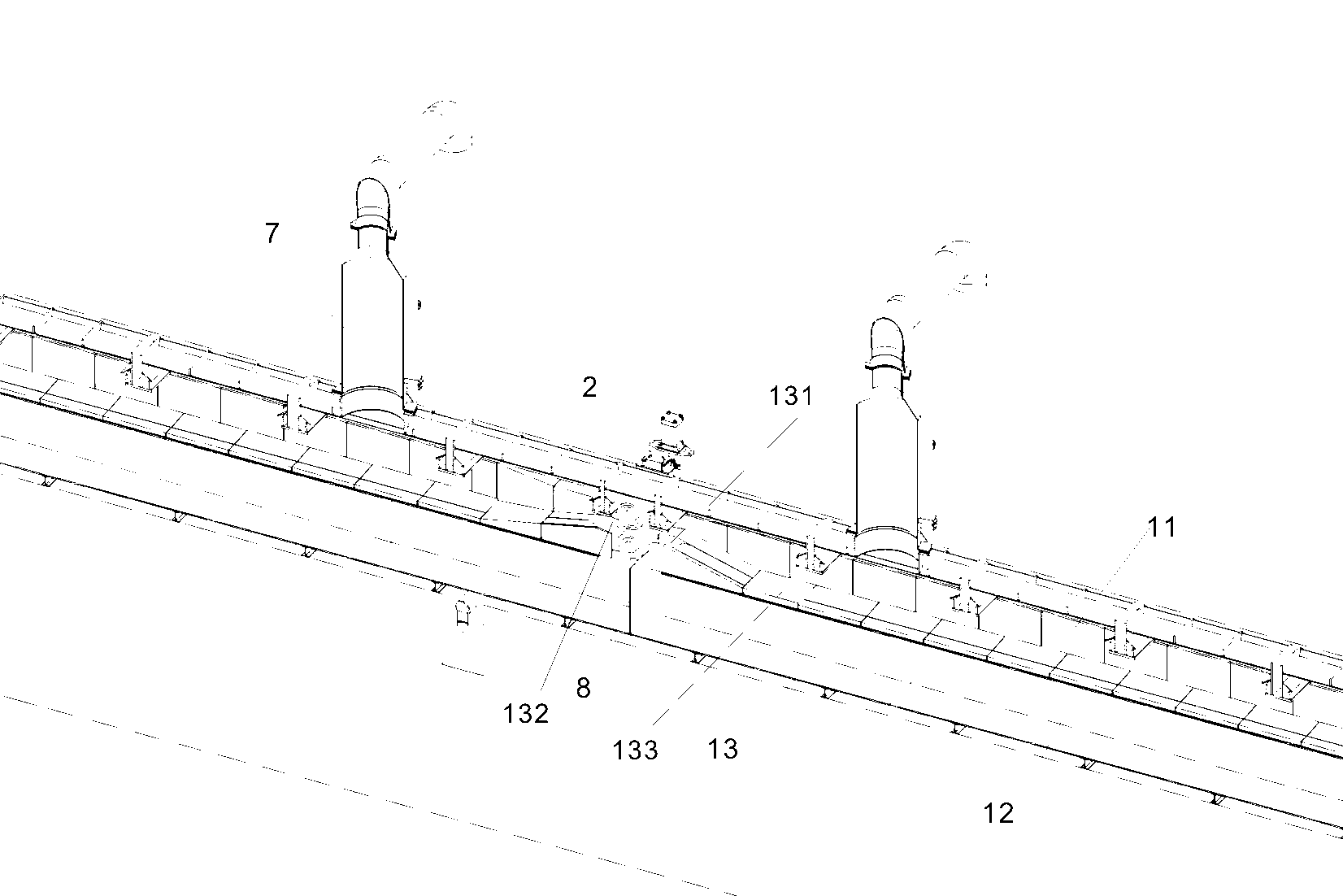

[0030] Such as figure 1 As shown, the present invention discloses an integrated pickling unit, which includes a tank body 1 divided into an upper layer and a lower layer by a partition 13, a squeeze roller 2, an inspection room 3, a circulation pump 4 and a heater 5; 13 Make the top layer of the tank body form the pickling tank 11, and the below of the dividing plate 13 is the acid recovery tank 12 (see image 3 ). Circulation pump 4 is connected with acid recovery tank 12 or maintenance room 3, and is connected with heater 5, and the output pipeline of heater 5 is connected with pickling tank 11; Driven by 4, it is heated by the heater 5, and the heated pickling solution enters the pickling tank 11 through the output pipe of the heater 5, and the steel to be washed is subjected to a spray or soaking pickling process, so that the pickling solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com