Non-isothermal mold pressing method for glass optical element

An optical element, non-isothermal technology, applied in the field of warm molding, can solve the problems of large temperature change during molding cycle, influence of mold service life and accuracy, etc., to reduce the temperature change range, improve mass production efficiency, and increase economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

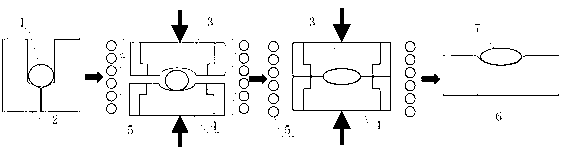

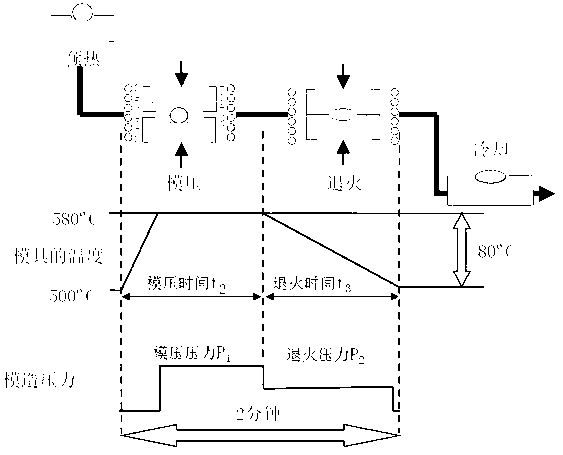

[0022] Such as figure 1 and figure 2 An embodiment of a non-isothermal molding method for glass optical elements of the present invention is shown, and the manufacturing steps include:

[0023] a. Preheating: the glass preform 1 is heated to 150°C-700°C in the preheating tank 2, and the temperature at this time is higher than the transformation temperature Tg of the material and is near the yield temperature At of the material;

[0024] b. Pressurization: Synchronized with preheating, the upper mold 3 and lower mold 4 in the mold are kept at 150°C-700°C under the action of the heating element 5, and the temperature at this time is maintained at 10°C below the transformation temperature Tg of the material degree; put the glass preform 1 with a temperature of 150°C-700°C into the molding cavity formed by the upper mold 3 and the lower mold 4, and use the heating element 5 to heat the glass preform 1, the upper mold 3 and the lower mold 4 Heating to the yield temperature At, ...

Embodiment 1

[0028] For the non-isothermal molding method for infrared chalcogenide glass (type IG6), the manufacturing steps include:

[0029] a. Preheating: glass preform 1 is heated to temperature T in preheating tank 2 1 ,T 1 is 212°C;

[0030] b. Pressurization: synchronized with preheating, the mold is kept at temperature T 2 , temperature T 2 175°C; put the glass preform 1 with a temperature of 212°C into the molding cavity, heat it to 215°C together, and apply a pressure of 0.5MPa to the upper mold 3 and the lower mold 4, and maintain it for 180s to preform the glass Part 1 is molded into a glass optical element 7;

[0031] c. Annealing: reduce the pressure from 0.5MPa to 0.3MPa and maintain it for 180s, slowly lower the temperature of the mold and glass optical element 7 to 175°C within the same period of time, and annealing will eliminate the internal stress of the glass optical element 7;

[0032] d. Cooling: the annealed glass optical element 7 is taken out from the mold c...

Embodiment 2

[0034] For the non-isothermal molding method for optical glass (type L-BAL35), the manufacturing steps include:

[0035] a. Preheating: glass preform 1 is heated to temperature T in preheating tank 2 1 ,T 1 is 567°C;

[0036] b. Pressurization: synchronized with preheating, the mold is kept at temperature T 2 , temperature T 2 517°C; put the glass preform 1 with a temperature of 567°C into the molding cavity, heat it to 570°C together, and apply a pressure of 0.6MPa to the upper mold 3 and the lower mold 4, and maintain it for 45s to preform the glass Part 1 is molded into a glass optical element 7;

[0037] c. Annealing: reduce the pressure from 0.6MPa to 0.4MPa, and maintain it for 45s, slowly lower the temperature of the mold and glass optical element 7 to 517°C within the same period of time, and annealing will eliminate the internal stress of the glass optical element 7;

[0038] d. Cooling: the annealed glass optical element 7 is taken out from the mold cavity, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com