Closed storage yard conveying system

A technology of conveying system and storage yard, which is applied in the field of closed storage yard conveying system, can solve the problems of large unloading drop of unloading machine, large overhead height, high crushing rate of block materials, etc., and achieve the reduction of stacking height, The overall height is reduced and the effect of reducing the crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

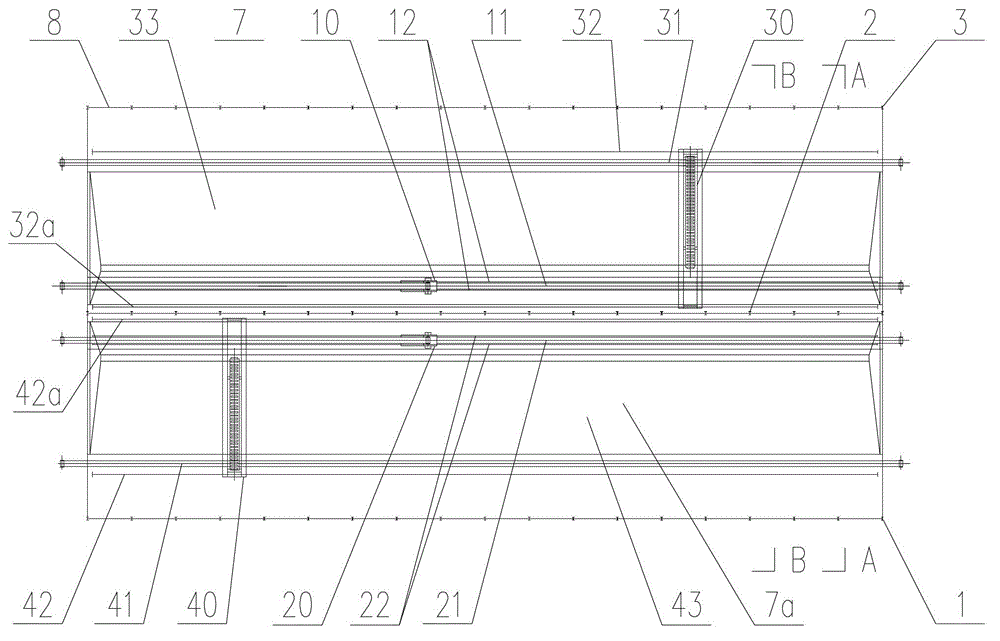

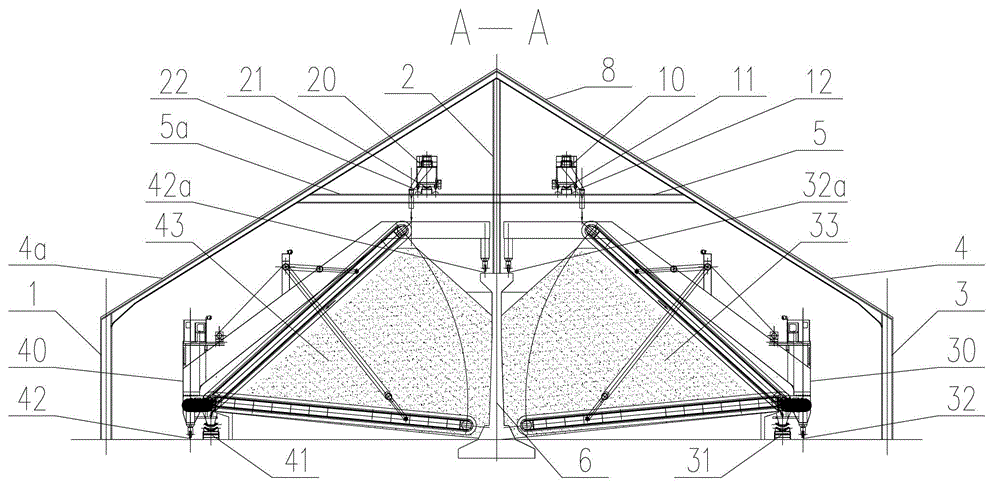

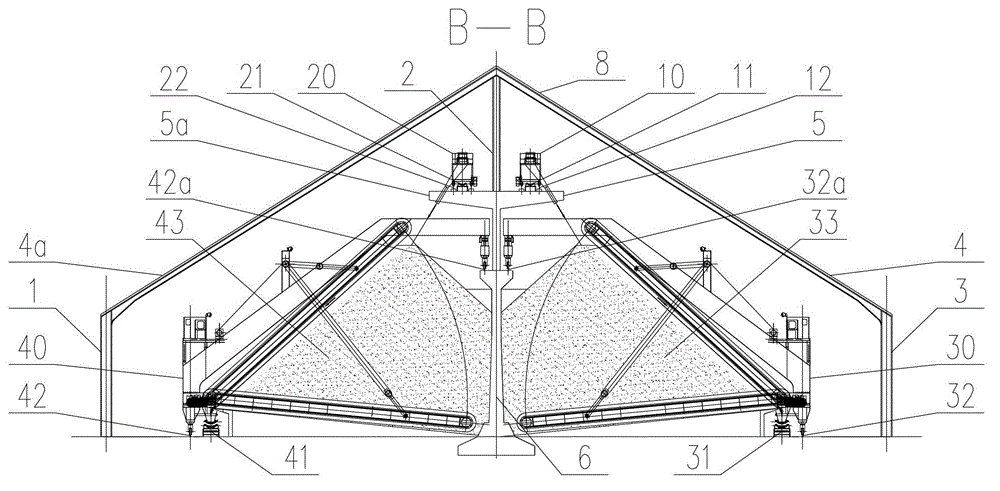

[0030] Such as Figures 4 to 6 As shown, the closed stockyard conveying system of the present invention is arranged as two spans, and each span is respectively provided with a stacker 50,60 and two rake type reclaimers 30 and 30a, 40 and 40a, and each span Machine 50,60 is arranged in the middle of two material rake type reclaimers 30 and 30a, 40 and 40a, to prevent mutual operation interference; Material rake type reclaimer 30 and 30a share two walking rails 32 and 32a, The material rake type reclaimer 40 and 40a share two profile tracks 42 and 42a, wherein the profile tracks 32, 42 are arranged on the ground, and 32a, 42a are arranged on the top of the retaining wall 6; each stacker 50, 60 are independently provided with the outer profiled tracks 52 and 62, and the inner sides of the stackers 50 and 60 utilize a profiled track 32 and 42 on the ground of the adjacent rake type reclaimers 30 and 30a, 40 and 40a; Each stacker 50,60 is respectively provided with a set of stacki...

Embodiment 2

[0035] Such as Figures 7 to 9 As shown, the closed stockyard conveying system of the present invention is arranged as two spans, and each span is respectively provided with a stacker 50,60 and two rake type reclaimers 30 and 30a, 40 and 40a, and each span Machine 50,60 is arranged in the middle of two material rake type reclaimers 30 and 30a, 40 and 40a, to prevent mutual operation interference; Each material rake type reclaimer 30 and 30a, 40 and 40a all have Two independently shaped rails 32 and 32a, 42 and 42a, wherein the shaped rails 32, 42 are set on the ground, and 32a, 42a are set on the column 9; each stocker 50, 60 is independently set on the outer side Out-of-shape tracks 52 and 62, stockers 50, 60 inboards then utilize the out-of-shape tracks 32 and 42 on the ground of adjacent material rake type reclaimers 30 and 30a, 40 and 40a; 50 and 60 are each provided with a set of stacking belt conveyors 51, 61; the rake reclaimers 30 and 30a share a set of reclaimer belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com