An industrial robot for material selection, clamping and handling in forging industry

An industrial robot and forging technology, which is applied in the field of material selection, clamping and handling industrial robots in the forging industry, can solve the problems of high labor intensity, scalding and burns, and hidden safety hazards, and achieve high work efficiency, low manufacturing and maintenance costs. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

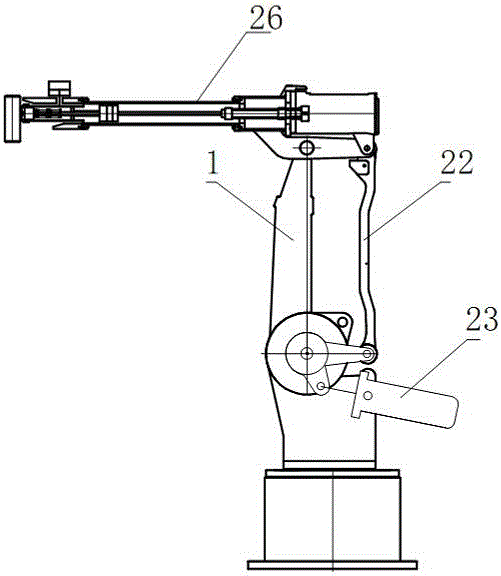

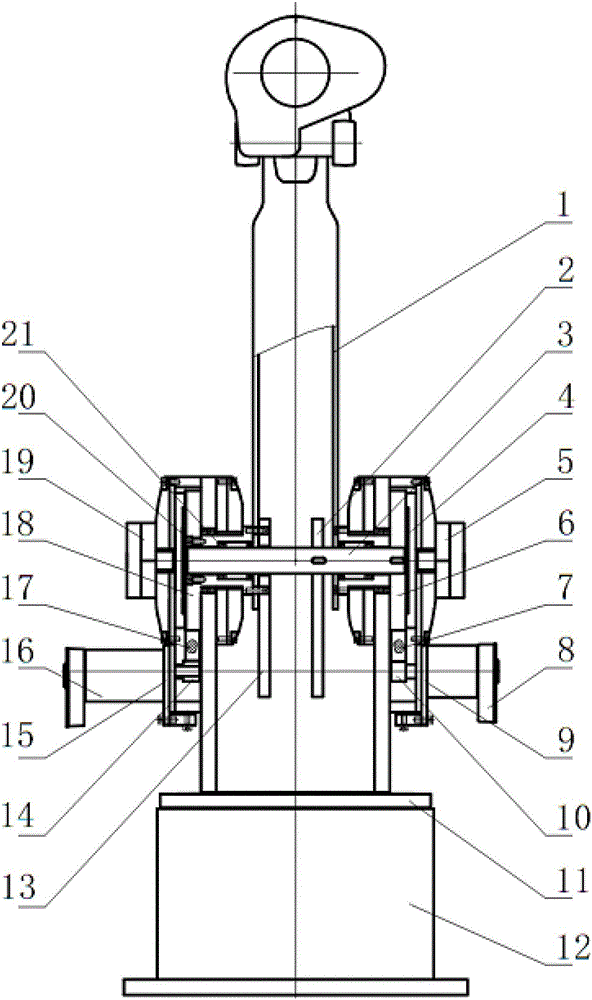

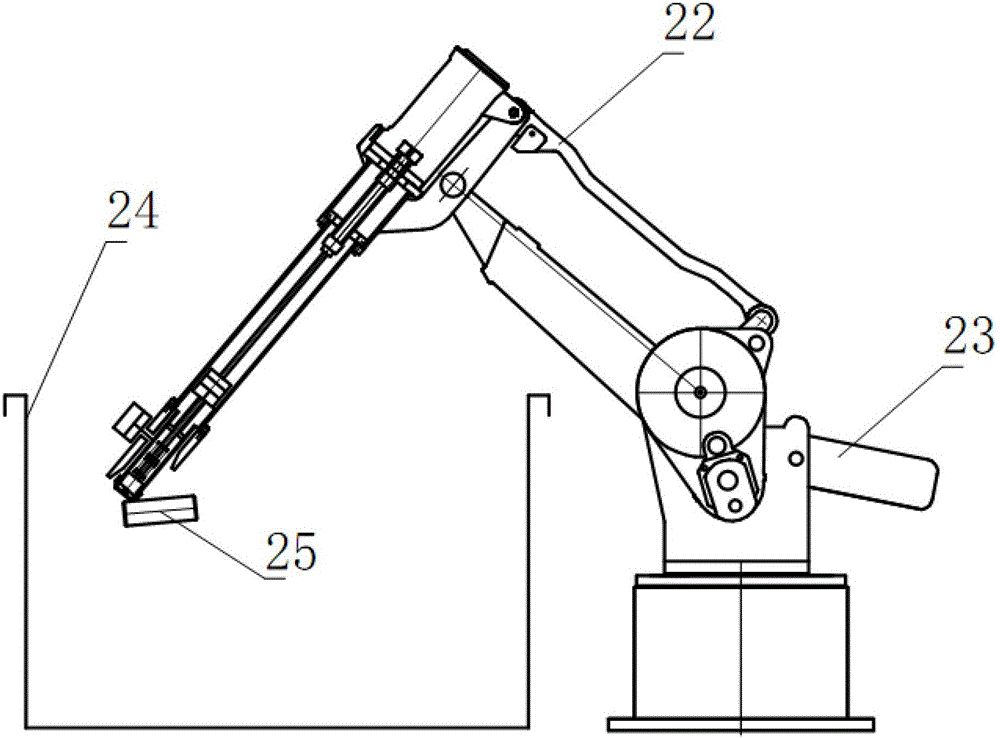

[0017] Such as Figure 1-5 Shown is an industrial robot for material selection and gripping in the forging industry, which includes a rotating base, a boom, a small arm, a suction and clamping device, a driving mechanism for the boom, and a driving mechanism for the small arm; the boom is installed on the rotating base, The arm is arranged on the head of the arm, and the workpiece clamping device is arranged on the arm; the arm is driven by the arm drive mechanism to swing with the transmission shaft, and the arm is driven by the arm The drive mechanism drives to swing with the forearm shaft.

[0018] Braking devices are provided in the boom driving mechanism and the small arm driving mechanism, and the braking devices include brake cylinders and brake pads, and brake through the expansion and contraction of the cylinders and the cooperation of the brake pads. The boom drive mechanism includes a boom synchronous motor 16, a small boom synchronous pulley 14 arranged on the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com