Separation buffering type shock absorber strut and automobile

A technology for separating buffers and shock absorbers, used in vehicle components, elastic suspensions, suspensions, etc., can solve the problems of not being able to meet the requirements of dynamic and static characteristics at the same time, reducing riding comfort and handling, poor structural stability, etc. The effect of stability, improving reliability, and increasing working radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

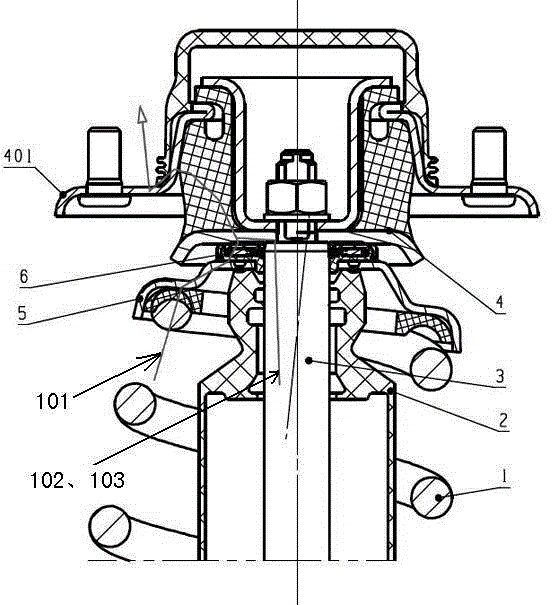

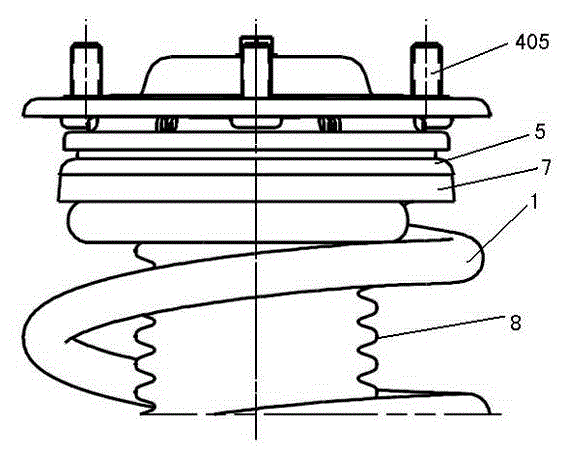

[0034] Figure 3 to Figure 5 The reference numerals in are: coil spring 1; buffer limit block 2; shock absorber 3; front suspension buffer assembly 4; bottom connecting plate 401; top connecting plate 402; first buffer member 403; 404; Fastener 405; Boss 406; Spring upper seat 5; Plane bearing 6; Second buffer 7; Dustproof cover 8; Nut 9; Elastic force transmission path 101; Path 103.

[0035] like Figure 3 to Figure 5 As shown, a separate buffer type shock absorber strut includes a coil spring 1 installed along the same axis, a buffer limit block 2, a shock absorber 3, a front suspension buffer assembly 4, a spring upper seat 5 and a plane bearing 6, Wherein, the front suspension buffer assembly 4 includes a bottom connecting plate 401 and a top connecting plate 402 that are entangled up and down to form a cavity, and the cavity is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com