Mining drill rod changing manipulator

A manipulator and mine-used technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as difficult operation for workers, and achieve the effects of simple manipulation, large working radius, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

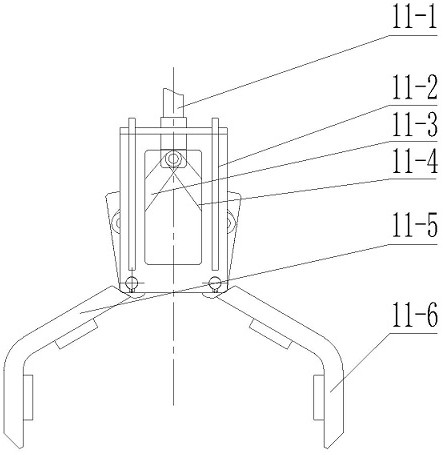

[0023] like figure 1 and figure 2 As shown, a mining drill changing manipulator includes a base 1 , a slewing bearing 2 , a lifting part, a translation part and a gripper assembly 11 .

[0024] The slewing bearing 2 is connected to the fixed base 1 and the bottom of the outer end of the inner sleeve 3 of the lifting part.

[0025] The inner bottom of the lift inner sleeve 3 is hinged to one end of the lift cylinder 5 , and the other end of the lift cylinder 5 is hinged to the inner top of the lift outer sleeve 4 sleeved outside the lift inner sleeve 3 . The outer sleeve 4 of the elevating part and the inner sleeve 3 of the elevating part adopt clearance fit. In order to facilitate the installation of the inner sleeve 3 of the lifting part, there are holes for the installation of the pin shaft and the oil outlet of the lifting cylinder 5 .

[0026] The top outer end of the outer sleeve 4 of the lifting part is fixed by the flange 6 to the outer sleeve 7 of the translation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com