Hydraulic power device of bear-loading hopping robot

A hydraulic power device, robot technology, applied in the direction of motor vehicles, mechanical equipment, transportation and packaging, etc., can solve the problems of small power/mass ratio, poor load-bearing capacity, complex robot leg structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

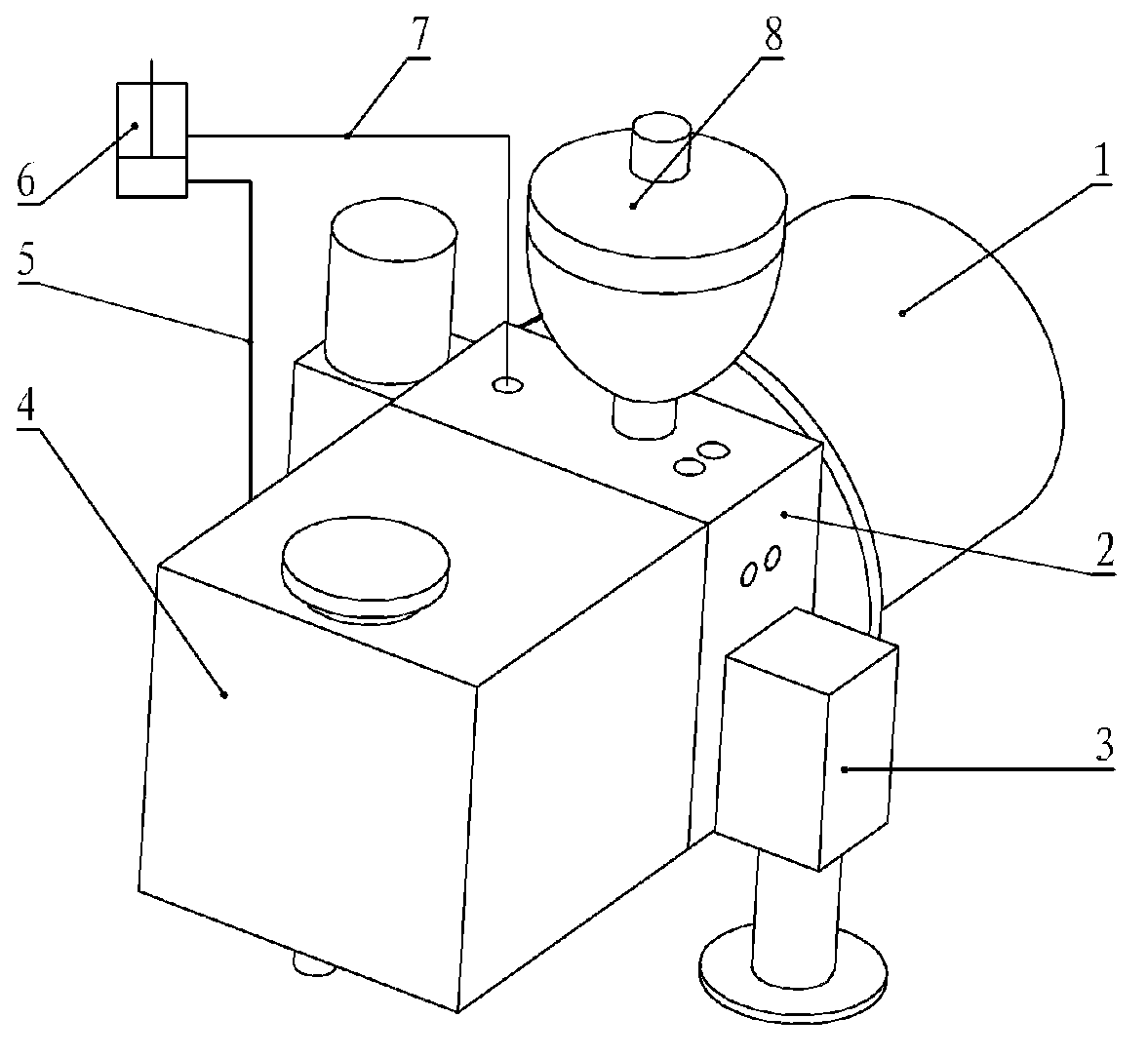

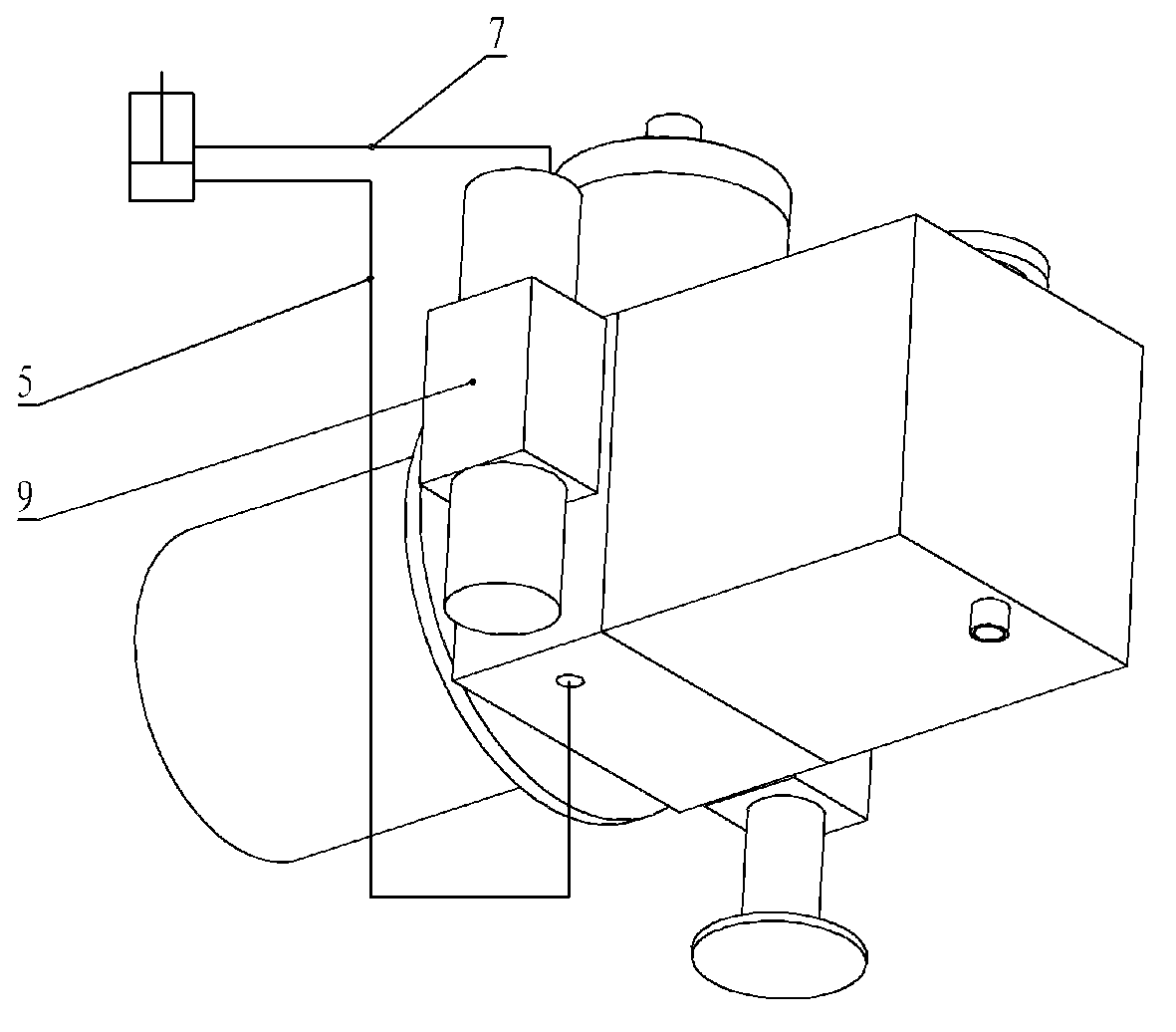

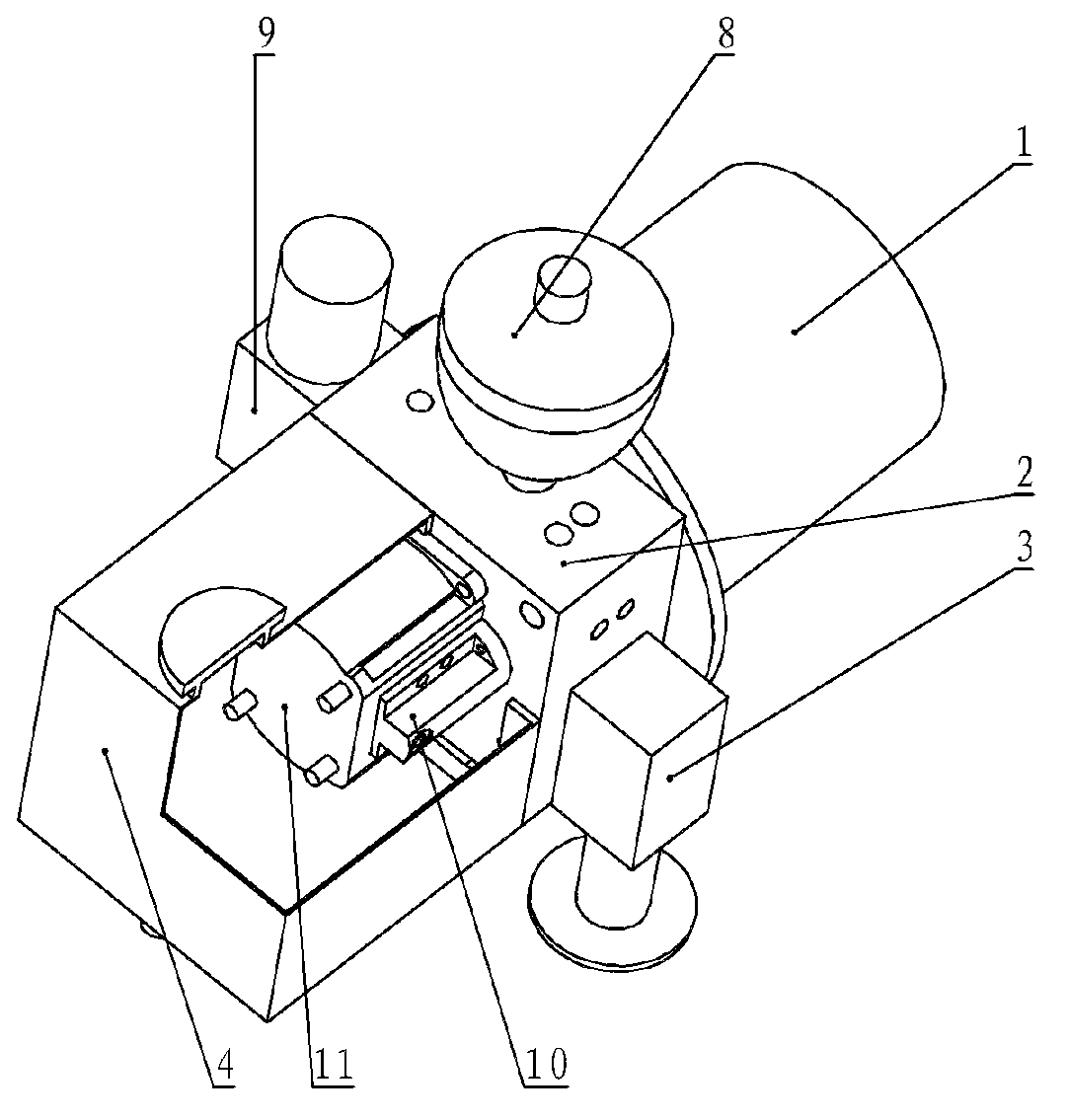

[0019] This embodiment is a hydraulic power device for a load-bearing bouncing robot.

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , the hydraulic power device of the load bouncing robot of the present invention adopts the hydraulic integrated block mode; the oil circuit integrated block 2 is equipped with a motor 1, an overflow valve 3, a fuel tank 4, an accumulator 8, a reversing valve 9, an oil guide block 10, and a gear Pump 11, coupling 12, first hydraulic pipe 5 and second hydraulic pipe 7; the oil port of each hydraulic component is matched with the oil hole on the installation surface of the corresponding oil circuit manifold 2; the hydraulic pipe The other end of the hydraulic cylinder 6 is connected to the hydraulic cylinder 6, which is the power actuator; the hydraulic cylinder 6 is fixedly installed at the joints of the robot to provide power for the joint movement of the robot. The oil circuit manifold 2 is located at the center of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com