Hub flash trimming machine

A technology of cutting machine and looping, applied in the field of mechanical processing, can solve problems such as affecting the production time of a single product, not ensuring the safety of personnel, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

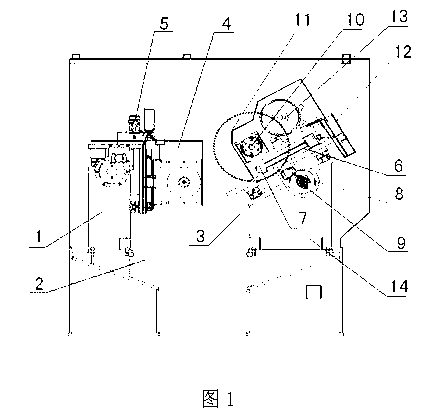

[0010] Depend on figure 1 It is known that a wheel hub ring removal machine is composed of a clamp 1, a bed 2, a small knife part 3, a large knife part 4 and a control part 5. The small knife part 3, the large knife part 4 and the control part 5 are arranged on the bed 2. The fixture 1 fixes the workpiece on the track of the bed 2, and the knife part is guided by a linear slide rail 6, a Z-axis drive screw 7, a screw drive hydraulic motor 8, an encoder 9, an X-axis screw 10, and a knife drive motor 11 , Knife handle 12 and knives main shaft 13 are formed, and knives main shaft 13 is laterally installed on the mounting seat 14 of lathe bed 2. The mounting plate of knife main shaft 13 is to be arranged on the mounting seat 14 in " 7 " font. The "7" shape arrangement improves the stability of the entire cutter, and there will be no phenomenon that the slider is prone to damage due to uneven force on the slider when the two guide rails are on the side. The bed is a one-piece wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com