Seedling clamping conveying device for peanut combined harvester

A technology for combine harvesters and conveying devices, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc. It can solve problems that affect the quality and efficiency of operations, uneven placement of peanut seedlings, and unreliable use, etc., to achieve High working efficiency, not easy to entangle peanut seedlings, neatly placed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

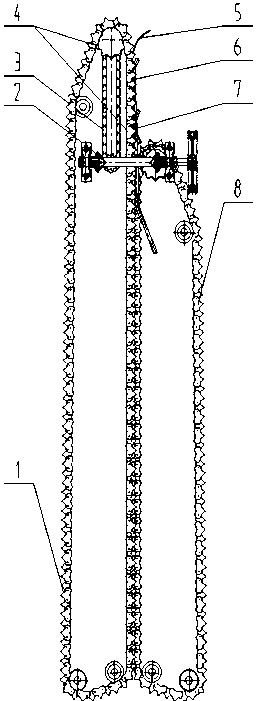

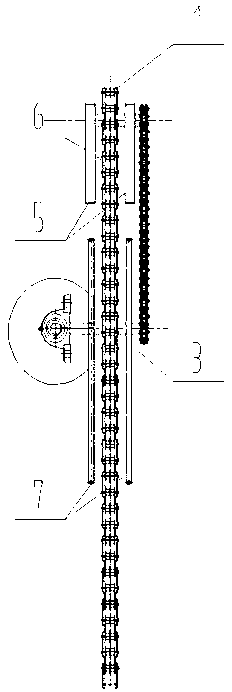

[0015] see figure 1 , figure 2 , the peanut combine harvester clipping conveying device mainly includes an annular short seedling clipping conveying chain 8 and its driving sprocket and driven sprocket, and is characterized in that it also includes an annular long seedling clipping conveying chain 1, and the annular short The annular surface of the seedling-clamping conveying chain 8 and the annular long seedling-clamping conveying chain 1 are on the same plane, and the chain in the middle of the two is close to form a common seedling-clamping conveying part. The conveying tail portion has a length difference; at the tail portion, the ring-shaped short seedling clamping conveying chain 8 leaves the position of the annular long seedling clamping conveying chain 1, and on the upper side and the lower side of the long conveying chain 11, there are seedling-introducing guide rods 7 and holding Bar 6, pressing and holding bar 6 and long conveying chain 11 are clamped and matched;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com