Blade element-momentum theory-based method for computing uneven stressed load of actuating disc

A technology of uniform force and calculation method, applied in the direction of calculation, electrical digital data processing, special data processing application, etc., can solve the problems of large rotating coverage area, high calculation accuracy, and the impossibility of completely consistent blade manufacturing and installation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

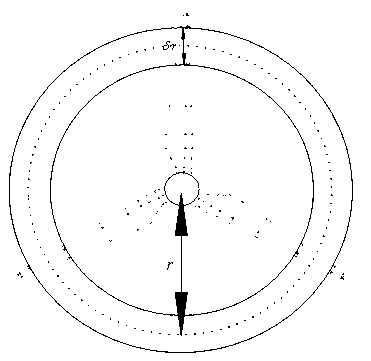

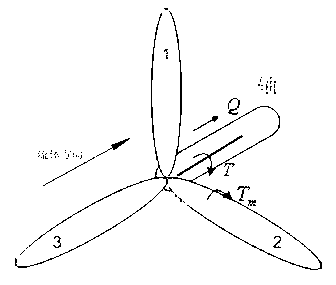

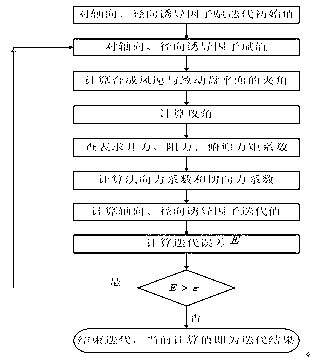

[0060] Axial induction factor corresponding to leaf element sweep annulus in the actuating disk and radial inducer The solution of can use iterative method, the specific steps are as follows:

[0061] Step 1: Set initial value, Generally, a small value and an iteration termination condition are acceptable is a very small positive real number;

[0062] Step 2: Calculating the corresponding th The angle between the synthetic wind speed on the blade element of the strip blade and the rotation plane of the actuating disk is calculated as follows:

[0063] Step 3: Calculate the corresponding first element in the actuating disc element sweep circle element angle of attack ,in is the pitch angle of the blade element corresponding to the blade;

[0064] Step 4: Angle of attack by leaf element , find the lift coefficient of the blade element according to its airfoil look-up table ,OK and the pitching moment coefficient ;

[0065] Step 5: Calculate the norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com