Forming method of tablet computer base

A tablet computer and molding method technology, which is applied in computing, instrumentation, electrical and digital data processing, etc., can solve the problem that the processing speed cannot meet the requirements of high-volume shipments in the electronics industry, the cost of cutting processing is not cheap, and the cost of materials cannot be effectively reduced. and other problems, to achieve the effect of good structural strength and heat dissipation, light weight and simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] refer to figure 1 , is a flow chart of the forming method of the tablet computer base of the present invention. The forming method of the tablet computer base of the present invention includes the following steps: providing a metal plate → providing a first mold set → forming the bottom edge → providing a second mold set → forming the side edge → forming a plastic part.

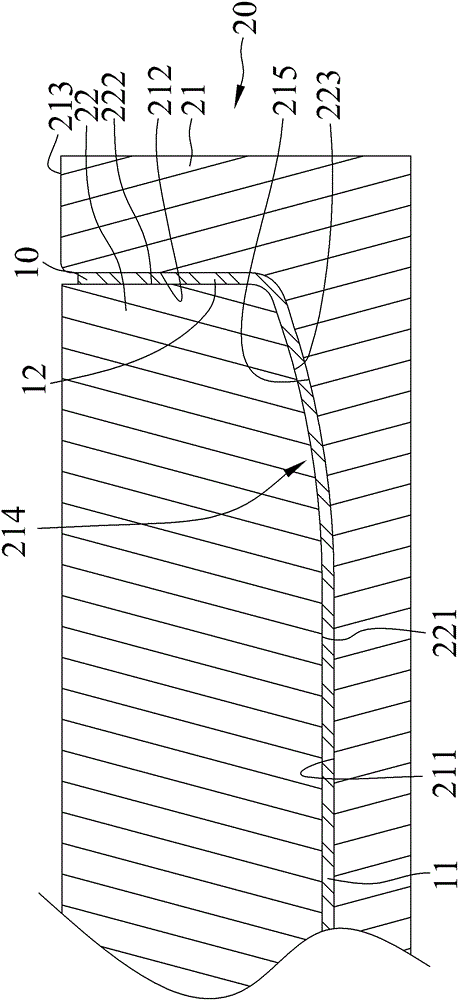

[0050] refer to figure 2 and image 3 , is a schematic diagram of forming the bottom edge of the forming method of the tablet computer base of the present invention. The forming method of the tablet computer base of the present invention comprises:

[0051] A metal plate 10 is provided: the metal plate 10 is an aluminum plate, an aluminum alloy plate or an aluminum-magnesium alloy plate. The metal plate 10 is an off-the-shelf thin plate, which is selected as a metal with light weight. Thin sheet material is less costly than bulk material.

[0052] A first mold set 20 is provided, and the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com