Hybrid power system using normal pressure MCFC (molten carbonate fuel cell) to recover CO2 in exhaust gas of gas turbine

A gas turbine and hybrid power technology, applied in the field of hybrid power systems, can solve the problems of pollutant gas emissions and low efficiency, and achieve the effect of low CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

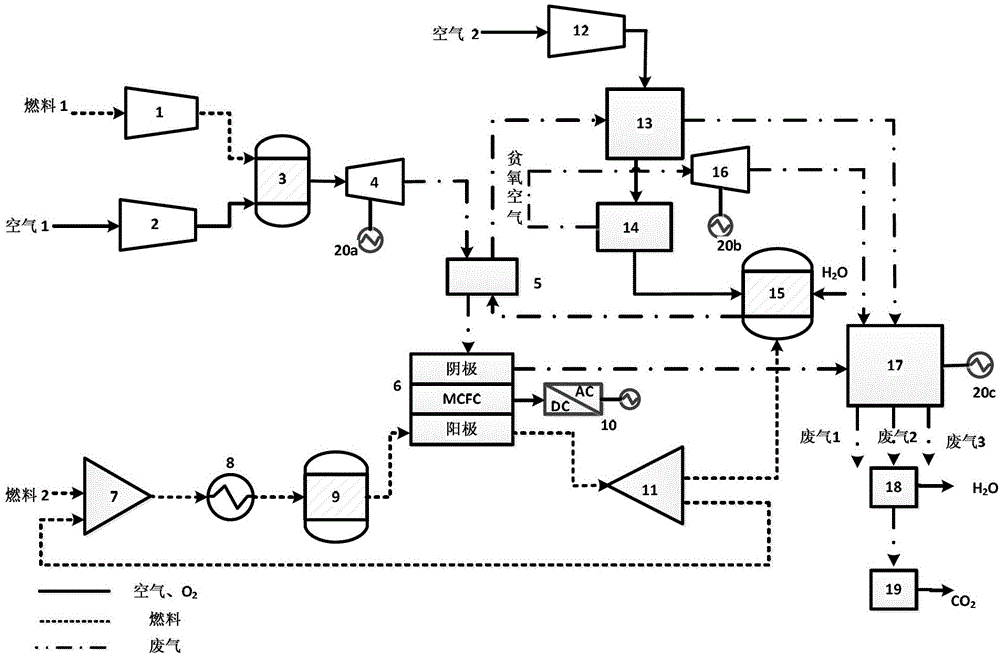

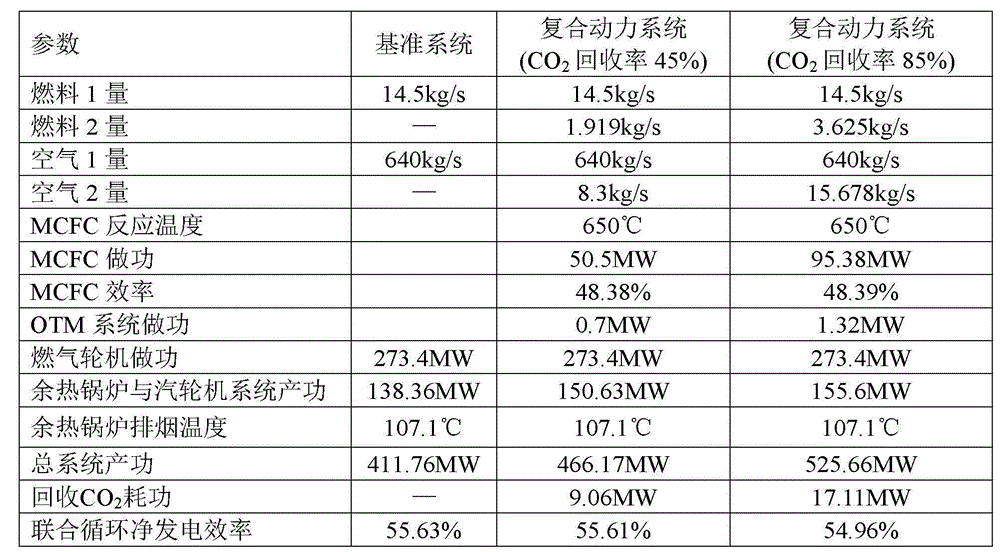

[0021] The invention provides a method for recovering CO in gas turbine exhaust by using atmospheric pressure MCFC 2 Achieving low CO in gas turbines 2 Discharge compound power system, the present invention will be further described below with reference to the drawings and specific embodiments.

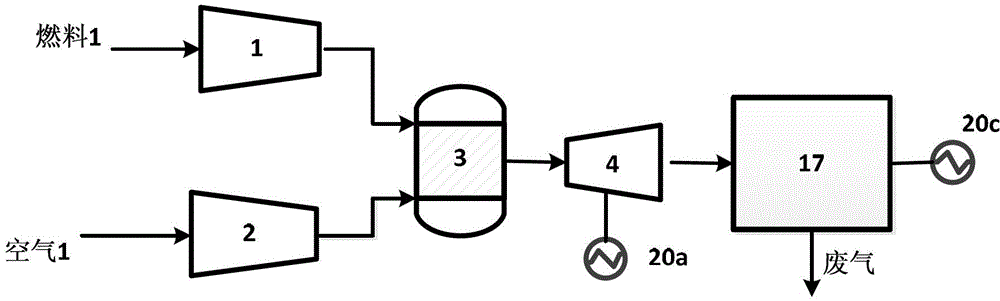

[0022] Does not recover CO 2 The benchmark system of the gas-steam combined cycle system such as figure 1 As shown: the first air and the first fuel are compressed by the first air compressor 1 and the fuel compressor 2 and sent into the combustor 3 for combustion, then the turbine 4 does work, and the generator 20a generates electricity for output, and then the high temperature Exhaust gas enters the waste heat boiler and steam turbine system 17 to generate steam to drive the steam turbine to generate power, and the generator 20c generates electricity for output, and finally the low-temperature exhaust gas is directly discharged into the atmosphere.

[0023] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com