Sulphobetaine metacrylic acid ester grafted polysulfone copolymer as well as preparation method and application of polysulfone copolymer

A technology of alkali methacrylate and sulfobeet, which is applied in the field of preparation of anti-fouling membranes, can solve problems such as difficult grafting reaction, and achieve excellent anti-protein and platelet effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]Add 1.8g CMPSU to 50ml DMSO, stir and dissolve for 12h, add 5.0g SBMA, stir and dissolve for 2h, pass nitrogen for 5h to remove oxygen, add 50mg CuCl, 100mg BPy, react at 60°C for 5h, stop nitrogen to terminate the reaction, and obtain DMSO solution containing SBMA-g-PSU product. After the copolymer was precipitated and dried, the elemental analysis was carried out, and the nitrogen element content was measured to be 2.05%, and the converted grafting rate was 52%.

Embodiment 2

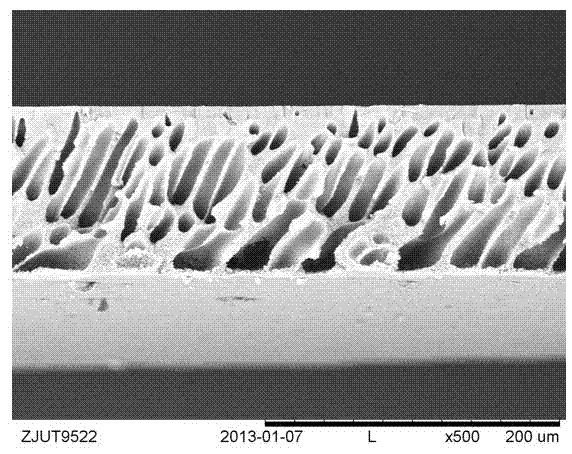

[0051] Dissolve 3.6 g of SBMA-PSU (37% grafting rate) and 3.6 g of PSU in 40 mL of NMP, stir for 12 h, and remove air bubbles. The film was scraped off on a glass plate with a spatula, and immersed in pure water to obtain a SBMA-grafted PSU flat film. The resulting flat membrane thickness is about 100 μm, the average membrane pore size is 0.67 μm, and the albumin rejection rate is 93%. Its structure is as figure 1 shown.

Embodiment 3

[0053] Dissolve 0.36 g of SBMA-PSU (37% grafting rate) and 3.6 g of PSU in 20 mL of NMP, stir for 12 h, and remove air bubbles. The film was scraped off on a glass plate with a spatula, and immersed in pure water to obtain a SBMA-grafted PSU flat film. The resulting flat membrane thickness is about 100 μm, the average membrane pore size is 0.21 μm, and the albumin rejection rate is 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com