Preparation of monodispersed magnetic fluorescent core-shell nano-microspheres

A nano-microsphere, monodisperse technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of magnetic fluorescent microspheres, such as particle size, uniformity and poor magnetic properties, cumbersome preparation process, and easy loss of fluorescent substances , to achieve the effect of simple equipment and operation process, monodispersity and improved magnetic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

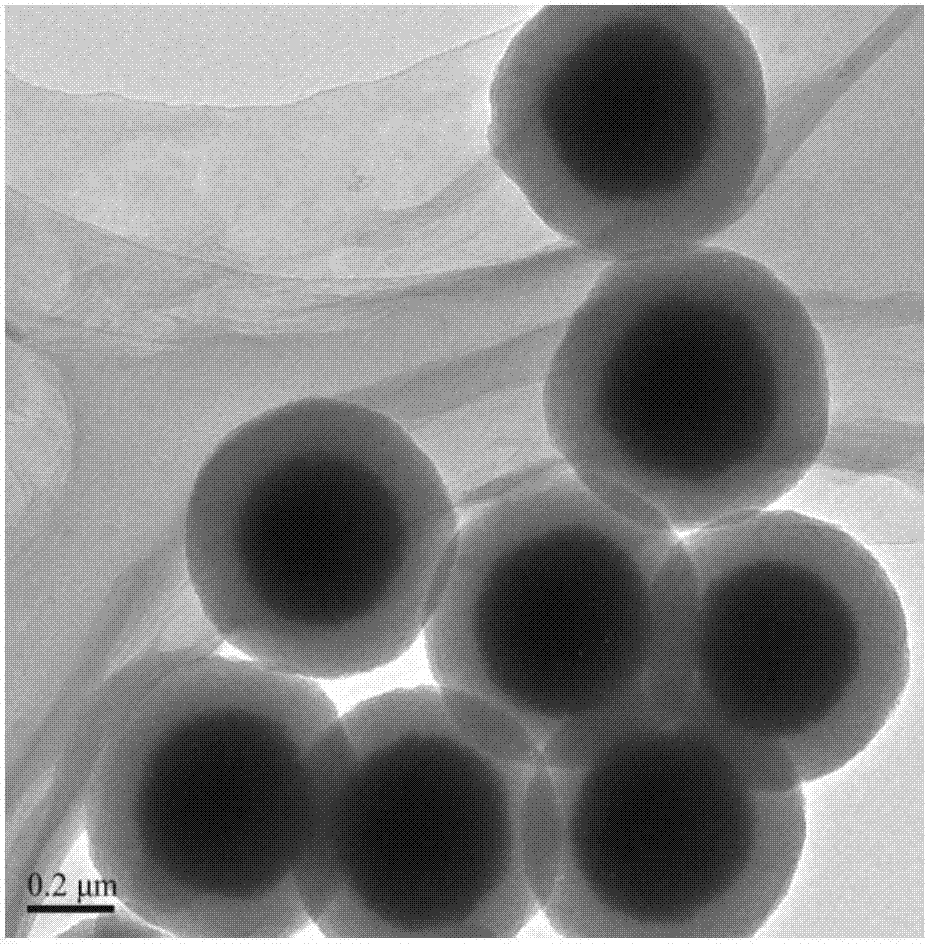

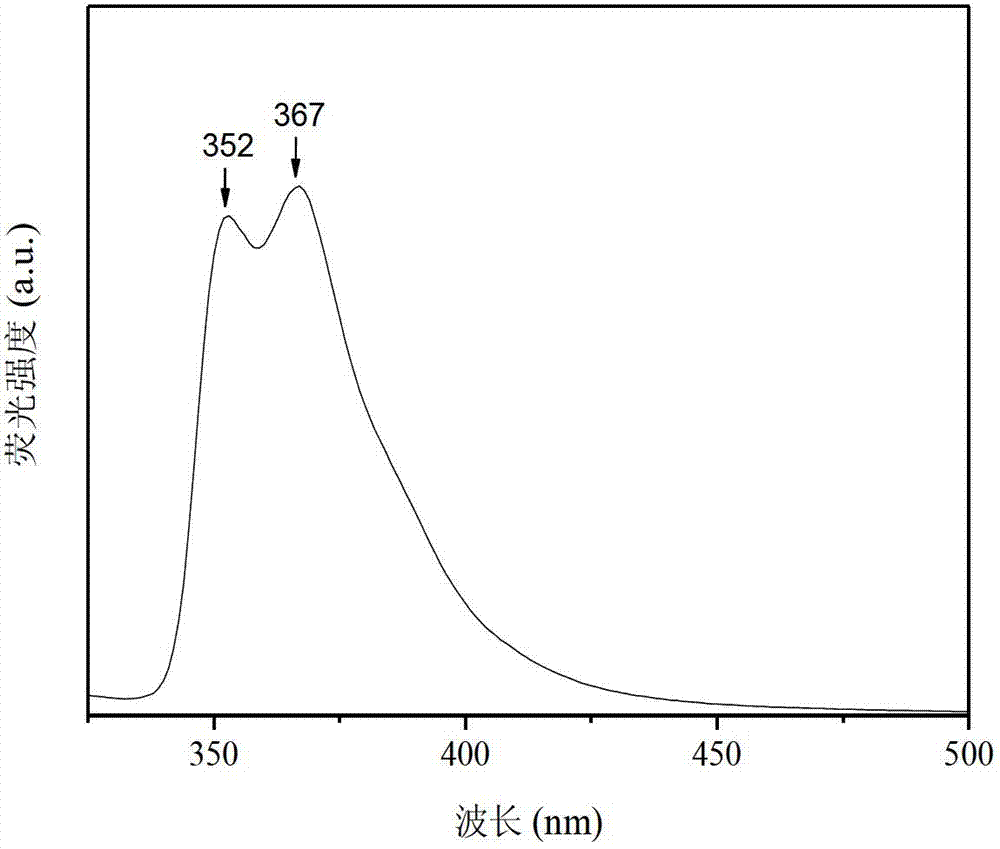

[0029] Embodiment 1: in the 100mL reactor that is equipped with condenser, add 70g acetonitrile and 10g methyl alcohol; Take by weighing 0.05g GMA (glycidyl methacrylate), 0.07g DVB (divinylbenzene) and 0.02g NVCz ( Vinyl carbazole) and 0.003g of AIBN (azobisisobutyronitrile), after shaking and dissolving, join in the reactor and mix well; 0.03g Fe 3 o 4 Add the microspheres into a 100mL reactor; gradually raise the temperature to 82°C, and polymerize for 3 hours; conduct magnetic separation on the obtained product, pour off the supernatant, add absolute ethanol to disperse by ultrasonic, and then magnetically separate; repeat this process for several times , to remove excess monomer and polymer. Vacuum drying at room temperature yields dark brown P(GMA-EGDMA-NVCz) / Fe 3 o 4 Magnetic Composite Microspheres.

[0030] After testing, the obtained magnetic P(GMA-EGDMA-NVCz) / Fe 3 o 4 The particle size of the microsphere is 750nm, the magnetic response is 38emu / g, and the magne...

Embodiment 2

[0031] Example 2: In a 100mL reactor equipped with a condenser, add 65g of acetonitrile, 10g of ethanol and 5g of acetone; weigh 0.07g of GMA (glycidyl methacrylate), 0.07g of DVB (divinylbenzene) and 0.04 gNVCz (vinyl carbazole) and 0.001g of BPO (dibenzoyl peroxide), after shaking and dissolving, add to the reactor and mix well; add 0.05g Fe 3 o 4 Add the microspheres into a 100mL reactor; gradually raise the temperature to 80°C, and polymerize for 6 hours; perform magnetic separation on the obtained product, pour off the upper layer, add absolute ethanol to disperse by ultrasonic, and then magnetically separate; repeat this process several times , to remove excess monomer and polymer. Vacuum drying at room temperature yields dark brown P(GMA-EGDMA-NVCz) / Fe 3 o 4 Magnetic Composite Microspheres.

[0032] After testing, the obtained magnetic P(GMA-EGDMA-NVCz) / Fe 3 o 4 The particle size of the microsphere is 660nm, the magnetic response is 50emu / g, and the magnetic conte...

Embodiment 3

[0033] Embodiment 3: in the 100mL reactor that is equipped with condenser, add 78g acetonitrile; Take by weighing 0.1g GMA (glycidyl methacrylate), 0.1g EGDMA (ethylene glycol dimethacrylate) and 0.05g NVCz (vinyl carbazole) and 0.005g of AIBN (azobisisobutyronitrile), after shaking and dissolving, add in the reactor and mix well; 0.07g Fe 3 o 4 Add the microspheres into a 100mL reactor; gradually raise the temperature to 85°C, and polymerize for 2.5 hours; magnetically separate the obtained product, pour off the supernatant, add absolute ethanol for ultrasonic dispersion, and then magnetically separate; repeat this process for several times to remove excess monomer and polymer. Vacuum drying at room temperature yields dark brown P(GMA-EGDMA-NVCz) / Fe 3 o 4 Magnetic Composite Microspheres.

[0034] After testing, the obtained magnetic P(GMA-EGDMA-NVCz) / Fe 3 o 4 The particle size of the microsphere is 620nm, the magnetic response is 48emu / g, and the magnetic content is 63w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Magnetic responsiveness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com