Press and method of utilizing press to press-fit stator and motor shell

A technology for press-fitting stators and presses, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., and can solve the problems of high labor intensity and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

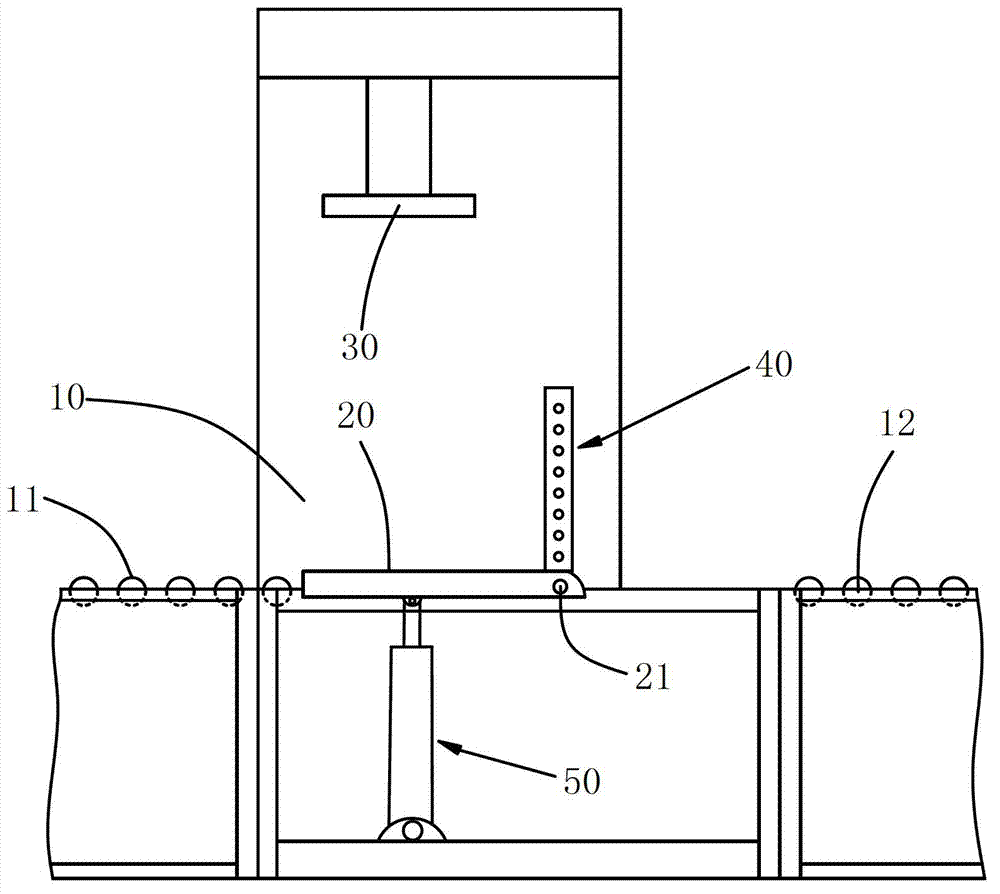

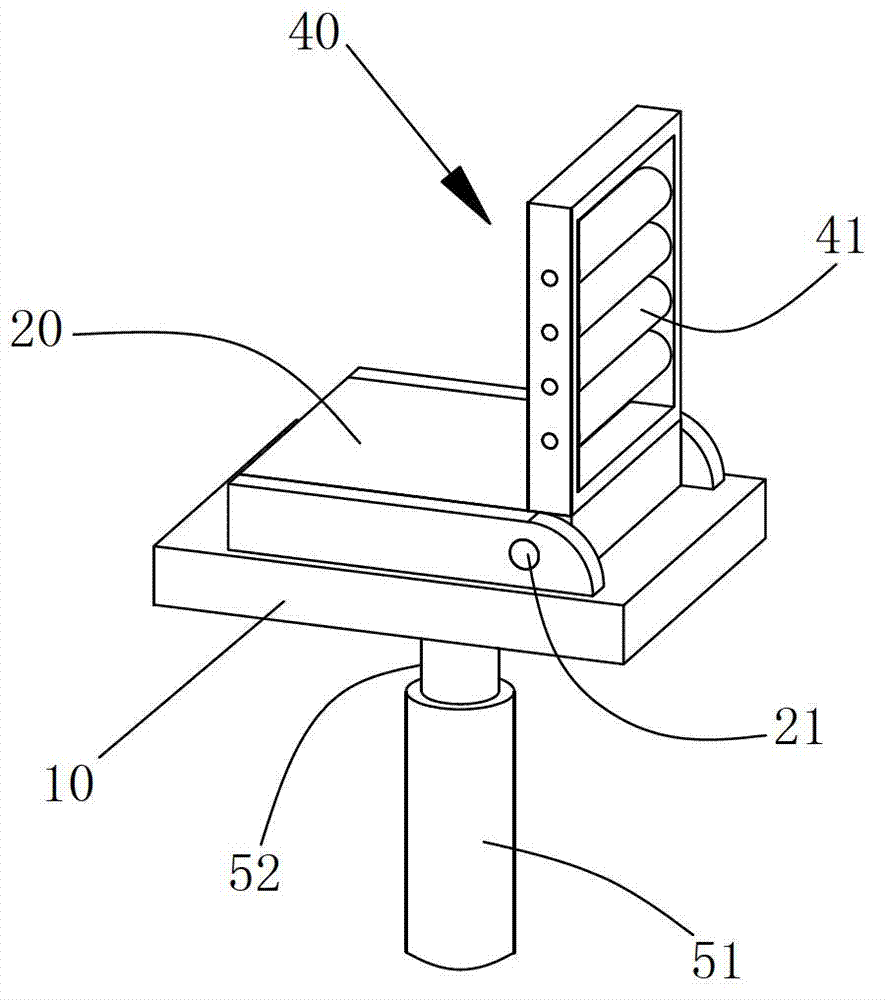

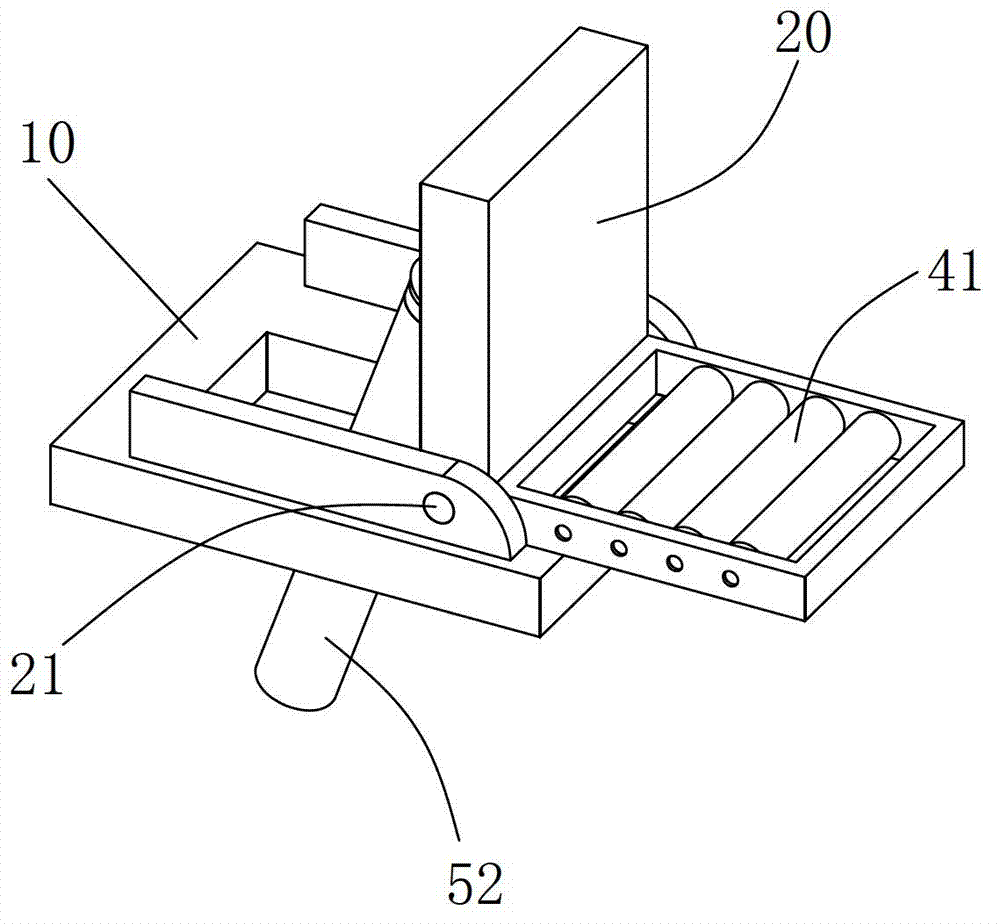

[0016] Such as figure 1 , 2 , 3, a press, including a frame 10, the frame 10 is provided with a pallet 20 for supporting the piece to be pressed and a pressure head 30 for pressing the piece to be pressed, which is arranged above the pallet 20 , the upper side of the pallet 20 is provided with a support assembly 40 for supporting the press-fit parts unloaded on the pallet 20, which is fixedly connected with it, and the support assembly 40 and the pallet 20 form an angle Type arrangement, the pallet 20 / support assembly 40 is hingedly connected with the frame 10, and the axis of the first hinge shaft 21 constituting the hinged connection is arranged parallel to the junction line between the pallet 20 and the support assembly 40, and the The frame 10 is also provided with a push mechanism 50 that pushes the pallet 20 and the support assembly 40 to turn over around the first hinge shaft 21. The push mechanism 50 pushes the pallet 20 to be in two states, one of which is the pallet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com