Wheat germ and lotus root starch powder, and its preparation method

A technology of wheat germ powder and wheat germ, applied in food preparation, application, food science, etc., can solve the problems of inconvenient use, poor taste, difficult storage of wheat germ, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The proportioning of raw material parts by weight is as follows:

[0049] Wheat Germ: 13.8

[0050] Lotus root powder: 35

[0051] Glucose powdered sugar: 12

[0052] Maltodextrin: 12

[0053] Tapioca starch: 23

[0054] White granulated sugar: 14

[0055] Jujube powder essence: 0.3-0.45.

[0056] The preparation process is as follows:

[0057] a. Clean and sieve the extracted fresh wheat germ to make it pure, then dry the wheat germ in a low-temperature drying oven at 60-80°C for 150 minutes, so that the moisture content is ≤6% by weight, and the temperature and time of drying can be controlled The wheat germ is golden yellow and has a wheat aroma. The low-temperature dried wheat germ is pulverized with a high-pressure airflow mill, so that it is finely passed through a 120-mesh sieve to obtain wheat germ powder;

[0058] b. Then use wheat germ powder, lotus root powder, glucose powder, tapioca starch, white sugar, and red date powder essence to carry out mixed...

Embodiment 2

[0063] The proportioning of raw material parts by weight is as follows:

[0064] Wheat Germ: 13

[0065] Lotus root powder: 34

[0066] Glucose powdered sugar: 12

[0067] Maltodextrin: 11

[0068] Tapioca Starch: 22

[0069] White granulated sugar: 13

[0070] Jujube powder essence: 0.4-0.42.

[0071] a. Dry the wheat germ with a 60-80°C low-temperature drying oven for 150 minutes to make the moisture ≤ 6% by weight, and pulverize the low-temperature dried wheat germ with a high-pressure airflow mill to finely pass through a 120-mesh sieve. Prepare wheat germ powder;

[0072] b. Then use wheat germ powder, lotus root powder, glucose powder, tapioca starch, white granulated sugar, and red date flavor to carry out mixed wet granulation, and the amount of water added is wheat germ powder + lotus root powder + maltodextrin + glucose powder + tapioca starch + white granulated sugar + red dates Powder essence: water=100:10 (dry mixture is prepared by mixing wheat germ powde...

Embodiment 3

[0077] The proportioning of raw material parts by weight is as follows:

[0078] Wheat Germ: 10-18

[0079] Lotus root powder: 30-40

[0080] Glucose powder: 8-15

[0081] Maltodextrin: 10-15

[0082] Tapioca starch: 20-26

[0083] White granulated sugar: 10-18

[0084] Jujube powder essence: 0.3-0.5

[0085] Preparation process is with embodiment 1

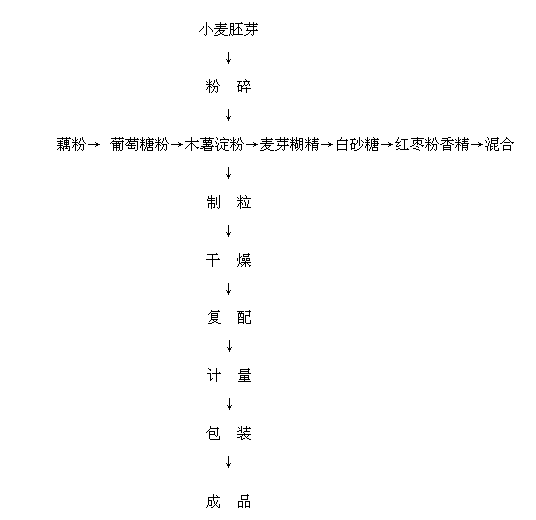

[0086] Production process flow of the present invention:

[0087] Wheat germ drying → crushing → granulation → drying → compounding → metering → packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com