Lever type dynamic load test platform with loads adjustable

A lever-type, test-bed technology, which is applied to the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problems of difficult maintenance, laborious and laborious adjustment, and large floor space, so as to achieve convenient, simple and applicable adjustment. Wide range and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

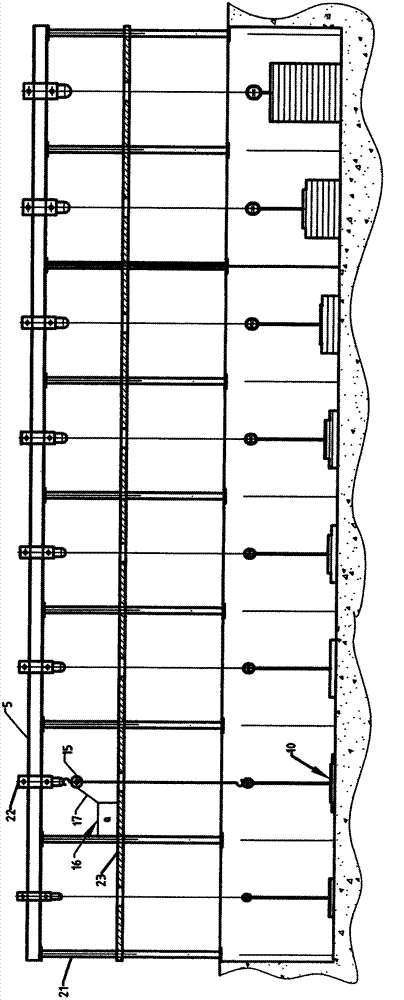

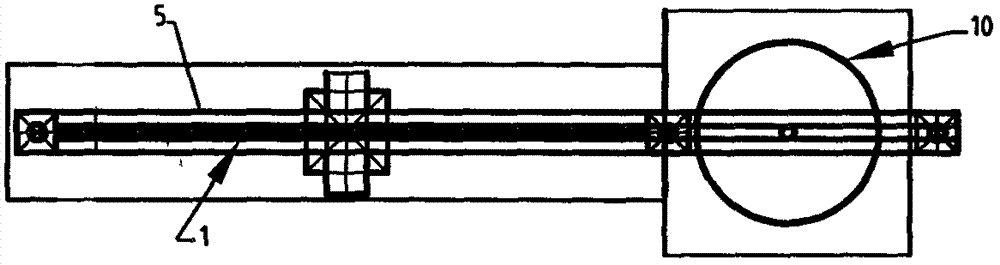

[0061] A lever-type adjustable load dynamic load test bench, such as figure 2 , 3 , shown in 4, it has lever 1, main column 2, column 3, girder 5, upper hanger device 6, upper hanger hook 14, lower hanger device 7, connecting part 9, external force source 10, fixed pulley 12 , multi-groove fixed pulley 13;

[0062] like Figure 10 Shown, one end of lever 1 is a moment arm, and the other end is a heavy arm, and moment arm side is provided with moment arm side installation hole 19, can be to open one, two, three, or a plurality of, what the present embodiment opens is five The heavy arm side has the heavy arm side installation hole 20, can be to open one, two, three, or a plurality of, what the present embodiment has opened is four holes; between the arms;

[0063] like Figure 9 As shown, the lower hanger device 7 is movably connected with the lever 1 through the arm side installation hole 19 and the heavy arm side installation hole 20. The lower hanger device 7 on the a...

Embodiment 2

[0076] A lever-type adjustable load dynamic load test bench, such as figure 2 , 21 , 4, its structure is basically the same as that of Embodiment 1, the only difference is that the lever-type adjustable load dynamic load test bench has two parallel arrangement structures, and can also be three, four, or multiple parallel arrangement structures.

Embodiment 3

[0078] A lever-type adjustable load dynamic load test bench, such as Figure 5 , 6 , 8, its structure is basically the same as that of Embodiment 1, the only difference is that it also has a transmission track 8, and the transmission track 8 is fixedly installed parallel to the main beam 5 at a certain distance and passed through a lever-type adjustable load dynamic load test bench. , is supported by column 3, and is fixed firmly through small beam 11.

[0079] The transmission track 8 is used for the final completion of the transmission product and the assembly and packaging product. The transmission track 8 transmits the product through the hanger trolley on the ring track. The transmission track 8 can be circular or other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com