Fully automatic vacuum saturated vapor pressure tester and test method for petroleum products

A petroleum product, fully automatic technology, applied in the direction of instruments, measuring devices, measuring fluid pressure, etc., can solve the problems of inapplicability of liquefied petroleum gas, reduce the labor intensity of testing, and inapplicability of measuring liquefied petroleum gas and oxygen-containing compounds, etc., to achieve The physical meaning is clear, the saturation is thorough, and the data is intuitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

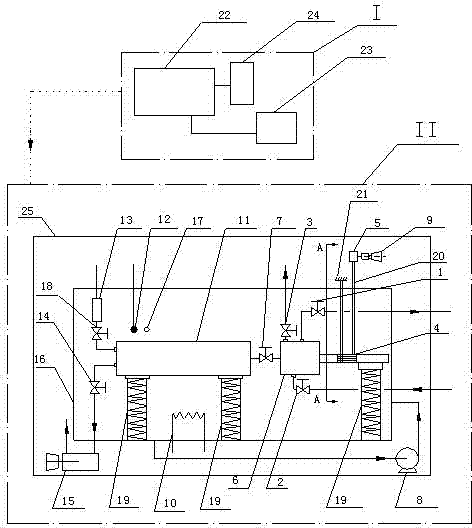

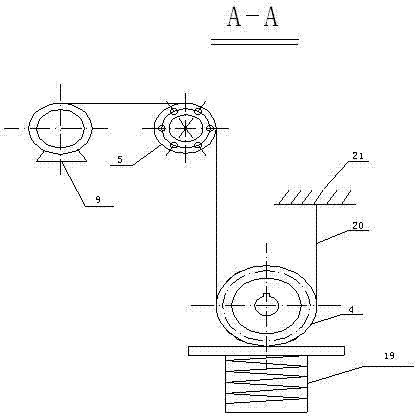

[0030] Such as figure 1 As shown, the embodiment of the present invention includes: upper computer I, lower computer II, oil return valve 1, oil inlet valve 2, vent valve 3, gear 4, pulley 5, oil chamber 6, oil outlet valve 7, circulating water pump 8 , motor 9, heater 10, pressure chamber 11, temperature sensor 12, pressure sensor 13, vacuum valve 14, vacuum pump 15, constant temperature water tub 16, thermometer 17, pressure sensor valve 18, spring buffer 19, chain 20, fixed Terminal 21, computer 22, printer 23, control cabinet 24, casing 25.

[0031] Such as figure 1 , 2 , the connection of each device is described as follows: (1) The oil to be tested outside the casing 25 is kept in communication with the oil chamber 6 through the oil inlet valve 2, and the vent valve 3 is installed above the oil chamber 6 to communicate with the atmosphere, and the oil chamber 6 The oil return valve 1 on the top is connected with the waste oil drum or other oil product recovery tank (n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com