Vacuum insulated panel core material and manufacturing method thereof

A technology for vacuum insulation boards and manufacturing methods, which is applied to fiberboards, heat exchange equipment, and pipelines through heat insulation, and can solve the problems of short heat preservation life, high thermal conductivity, and bulky space in available space, and achieve stable and reliable quality. Controlling, reducing thermal conductivity, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

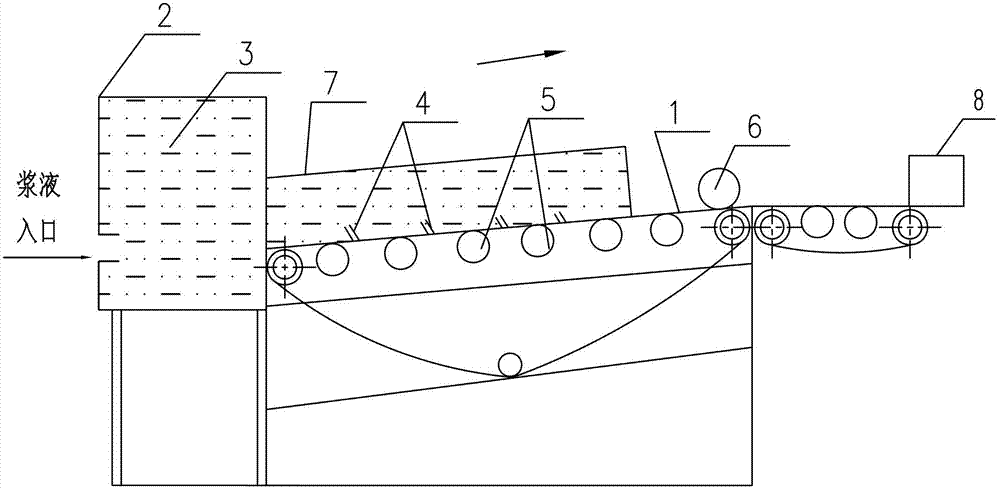

Image

Examples

example 1

[0030] The vacuum insulation panel core material of this example, the vacuum insulation panel core material is made of glass fiber chopped strands with a diameter of 6-13um and a length of 4-20mm drawn by wire drawing and a flame with a diameter of 1.0-4.0um and a length of 1-5mm The glass fiber cotton produced by the method is mixed; the glass fiber cotton produced by the flame method accounts for 20wt%, the glass fiber chopped strands produced by the wire drawing method account for 80wt%, and the core material thickness in the finished vacuum insulation panel is 15 ±1mm, the thermal conductivity of the vacuum insulation panel is ≤0.0024W / m.k.

[0031] The above-mentioned manufacturing method of the core material of the vacuum insulation panel, the specific steps of the manufacturing method are as follows:

[0032] (1) Take the glass fiber chopped strands produced by the wire drawing method with a diameter of 6-13um and a length of 4-20mm and the glass fiber wool produced by ...

Embodiment 2

[0044] The core material of the vacuum insulation panel in this example is a mixture of glass fiber chopped strands produced by wire drawing with a diameter of 6-13um and a length of 4-20mm and glass fiber wool produced by a flame method with a diameter of 1.0-4um and a length of 1-5mm Made; the glass fiber cotton produced by the flame method accounts for 10wt%, the glass fiber chopped strands produced by the drawing method accounts for 90wt%, and the core material thickness in the finished product of the vacuum insulation panel is 15 ± 1mm. The thermal conductivity of the insulation board is ≤0.0022W / m.k.

[0045] The manufacturing method of the core material of the vacuum insulation panel of this example includes the following steps:

[0046] (1) Take the glass fiber chopped strands produced by the wire drawing method with a diameter of 6-13um and a length of 4-20mm and the glass fiber wool produced by the flame method with a diameter of 1.0-4um and a length of 1-5mm; The p...

Embodiment 3

[0055] The core material of the vacuum insulation panel in this embodiment is made of glass fiber chopped strands produced by wire drawing with a diameter of 6-13um and a length of 4-20mm and glass fiber wool produced by a flame method with a diameter of 1.0-4um and a length of 1-5mm It is made by mixing; the glass fiber wool produced by the flame method accounts for 15wt%, the glass fiber chopped strands produced by the drawing method accounts for 85wt%, and the thermal conductivity of the finished vacuum insulation panel is ≤0.0021W / m.k.

[0056] The method for manufacturing the core material of the vacuum insulation panel in this embodiment includes the following specific steps:

[0057] (1) Take the glass fiber chopped strands produced by the wire drawing method with a diameter of 6-13um and a length of 4-20mm and the glass fiber wool produced by the flame method with a diameter of 1.0-4um and a length of 1-5mm; The proportion of glass fiber cotton is 15wt%, and the propor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com