Multi-point sealing apparatus for auxiliary high-pressure water jet of cutting mechanism of digging device

A high-pressure water jet and sealing device technology, used in hydraulic mining, earth-moving drilling, slitting machinery, etc., can solve the problems of easy failure and leakage, poor rotary sealing effect, affecting the parts in the cutting box, etc. Good effect, long sealing time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

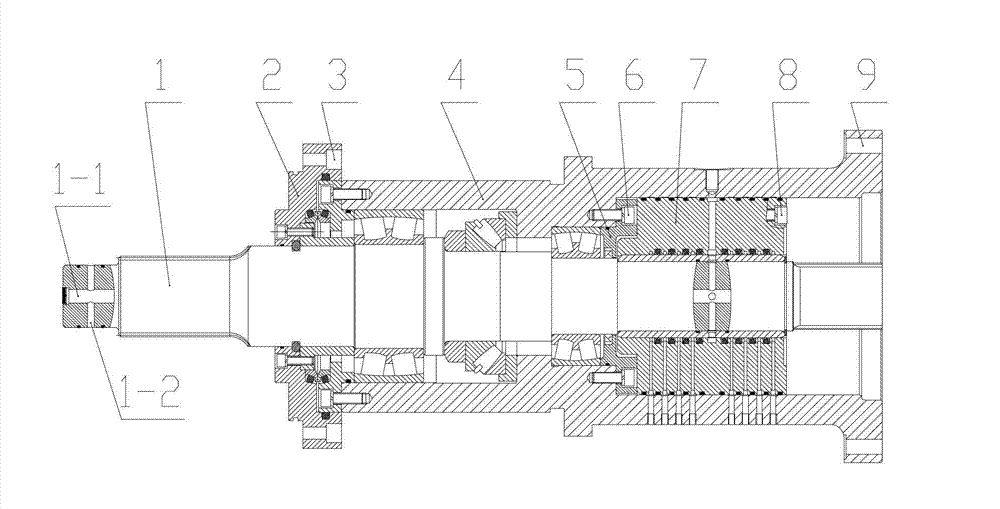

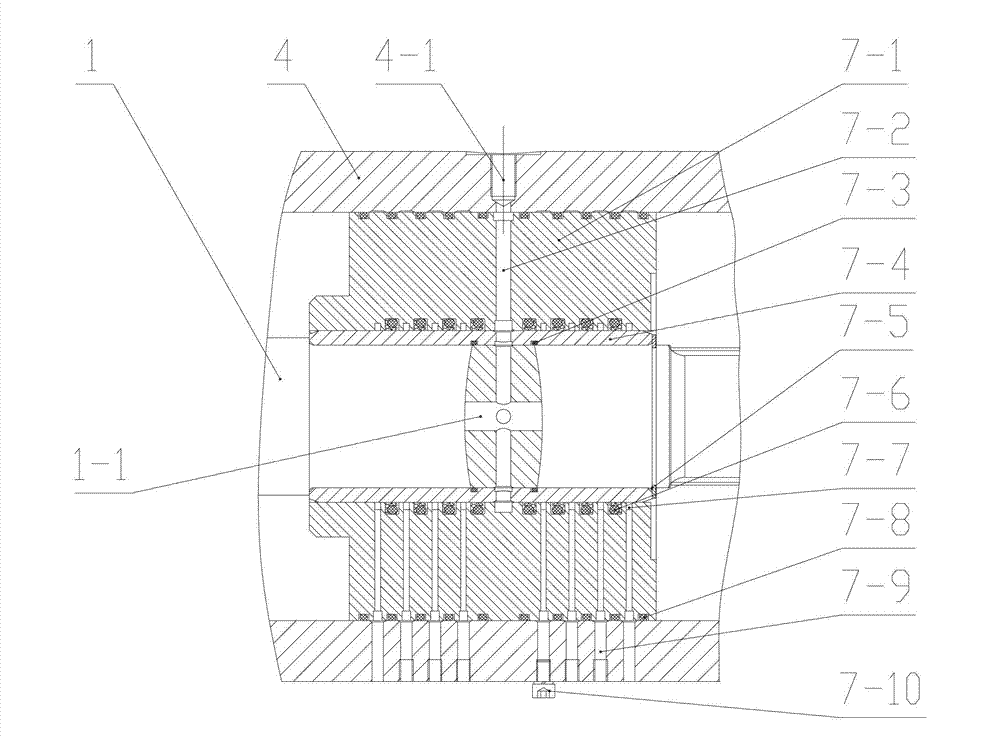

[0016] Such as figure 1 with 2 As shown, the multi-point sealing device 7 of the present invention is arranged between the cutting box 4 and the cutting shaft 1 . The multi-point sealing device 7 includes a water guide casing 7-1 and a water guide casing 7-4, and the water guide casing 7-4 and the water guide casing 7-1 are sequentially set on the cutting shaft 1 and the cutting mechanism of the mining equipment. Between cutting box 4. The left end of the water guide shell 7-1 is against the end cover 5, and the right end of the water guide shell 7-1 is fixed with the cutting box 4 by the bolt 3 8; the right end of the water guide sleeve 7-4 is passed through the retaining ring 7-5 It is axially fixed with the cutting shaft 1; the water guide sleeve 7-4 and the water guide housing 7-1 can freely rotate.

[0017] On the water guide shell 7-1, the water guide sleeve 7-4 and the cutting shaft 1, a water inlet 7-2 is arranged radially through, and the upper and lower ends of th...

Embodiment 2

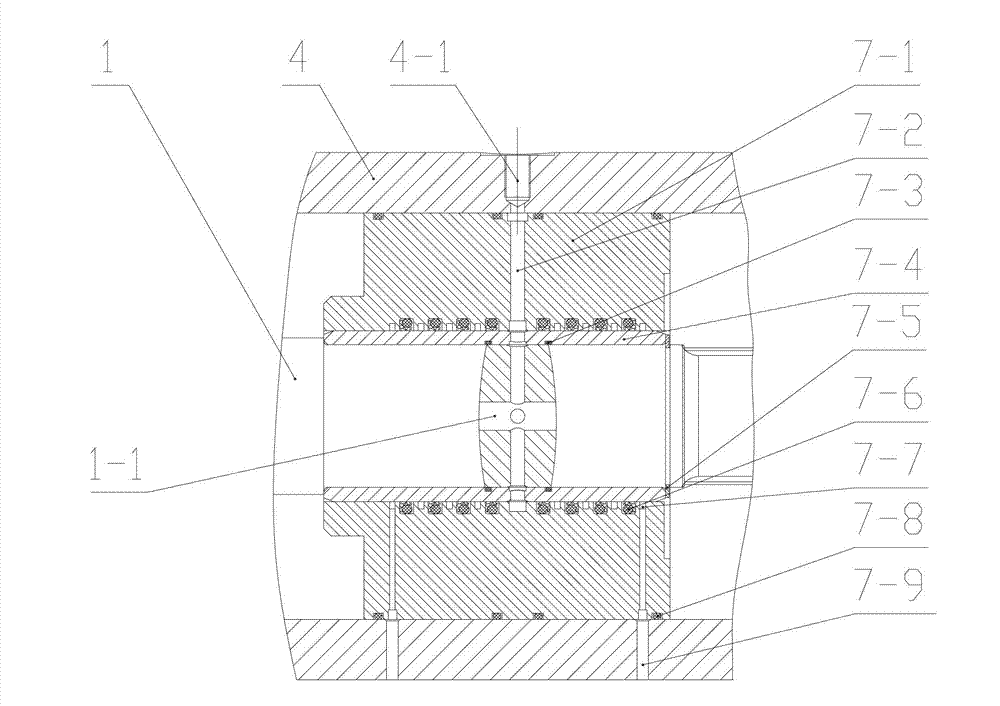

[0021] Such as figure 1 with 3 As shown, the difference between embodiment two and embodiment one is: change the number of discharge channels 7-7 and leakage channels 7-9 on both sides of the water inlet channel 7-2 from four to one, and the discharge channels 7-7 It is arranged on the outside of the tooth-shaped combined seal 7-6 farthest away from the water inlet 7-2. When the excavation equipment cutting mechanism is working, once water flows out from the leaking channel 7-9, it indicates that the entire multi-point sealing device 7 is invalid, and it is necessary to check and replace the relevant seals.

[0022] The multi-point sealing device 7 of the second embodiment has a simple and reliable structure, can effectively monitor the effective sealing time of the entire tooth-shaped combined seal 7-6, and is suitable for high-pressure water jet rotary sealing assisted by cutting mechanisms of mining equipment in engineering applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com