Reciprocating impact tunnel boring machine

A technology of percussion drill and excavator, applied in the field of mine excavation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

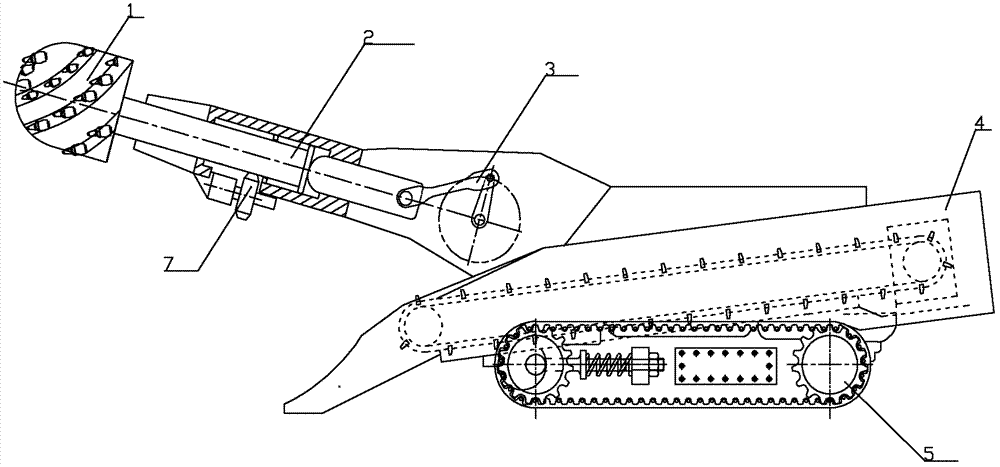

[0049] figure 1 and figure 2 It is the reciprocating impact drilling machine described in Embodiment 1. The drilling machine includes a fuselage 4 , and the fuselage 4 includes a traveling mechanism 5 and an impact rotary drilling mechanism 2 , wherein the traveling mechanism 5 is arranged at the bottom of the fuselage 4 . The impact rotary drilling mechanism 2 includes an impact device 3, a rotary drilling device 7 and a drill bit 1, the rotary drilling device 7 is slidingly connected with the drill bit 1, and the rotary drilling device 7 drives the drill bit 1 to rotate. Simultaneously, the impact device 3 impacts the drill bit 1, and the impact device 3 is driven in cooperation with the rotary drilling device 7 to make the drill bit 1 impact and rotate. The traveling mechanism 5 drives the body 4 to walk, and the body 4 walks to drive the impact rotary drill 2 to walk. Fuselage travel makes 3 block back drill bit 1 through rock wall, makes drill bit realize rotary drill...

Embodiment 2

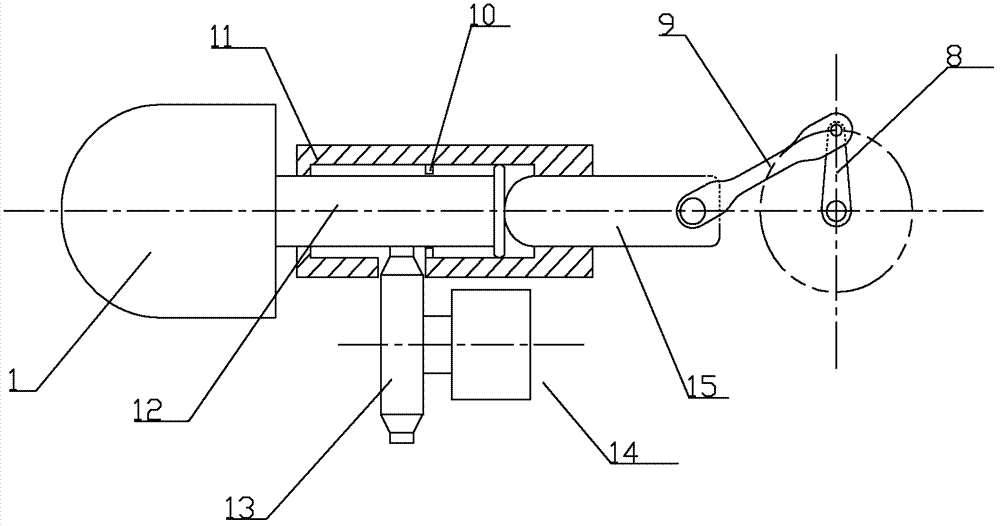

[0054] image 3 and Figure 4 It is the reciprocating impact drilling machine described in Embodiment 2. In this embodiment, the rotary drilling device 7 includes a spline column rotary drilling device. The impact device includes an impact power component 8, a connecting rod 9 and an impactor 15. One end of the connecting rod 9 is connected to the impact power component 8, and the other end Connect with impactor 15. The impact power part 8 drives the connecting rod 9 to reciprocate, and the connecting rod 9 drives the impactor 15 to impact. The front end of the spline column rotary drilling device is provided with a spline sleeve bit corresponding to the spline column rotary drilling device, and the spline column rotary drilling device is arranged on the impactor 15, and the impactor 15 drives the spline column rotary drilling device and the spline The drill bit reciprocates and impacts, the spline column rotary drilling device drives the drill bit to rotate, the drill bit ...

Embodiment 3

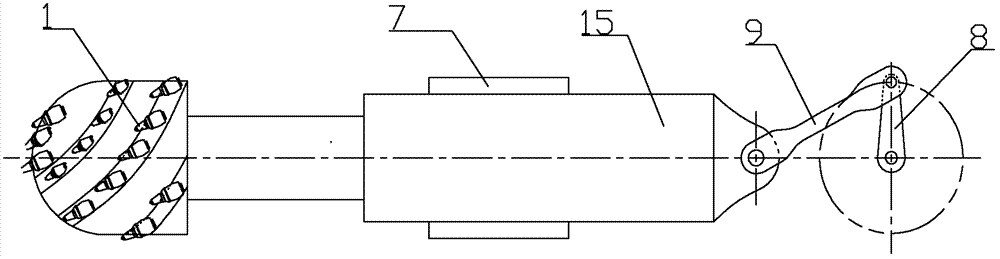

[0058] Figure 5 It is the reciprocating impact drilling machine described in embodiment 3. In this embodiment, the rotary drilling device includes a spline column rotary drilling device, the spline column rotary drilling device is arranged on the fuselage, the impact device includes an impact power part 8, a connecting rod 9 and an impactor 15, and the impact power part 8 Set on the fuselage, the impact power part 8 drives the connecting rod 9 to reciprocate, and the connecting rod 9 drives the impactor 15 to impact. The spline column rotary drilling device includes a spline column 18 and a rotary drilling power component 17. The spline column rotary drilling device The front end of the spline sleeve is provided with a spline sleeve bit corresponding to the spline column rotary drilling device, and the rear portion of the spline sleeve drill bit is provided with a spline sleeve 19 corresponding to the spline column. The spline sleeve 19 is a cavity structure, and the spline s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com