Cast-in-place pile used in high concentration saline solution corrosion environment and construction method thereof

A high-concentration salt and corrosive environment technology, used in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of difficult inspection and maintenance work, difficult to be found, etc. mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

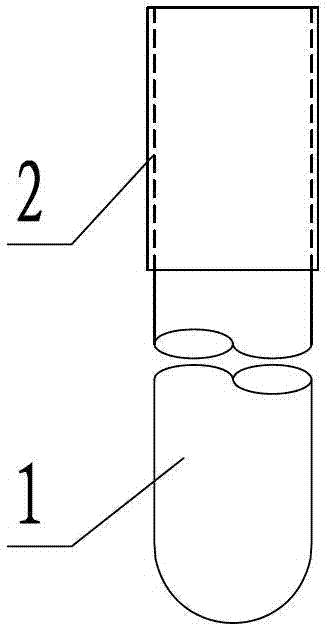

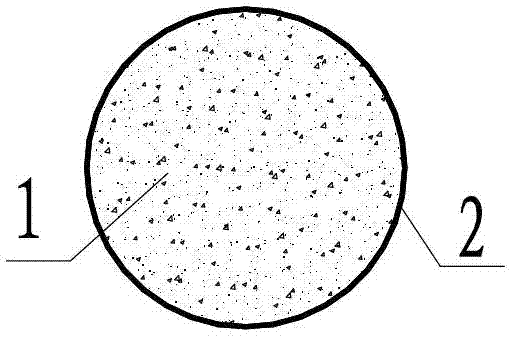

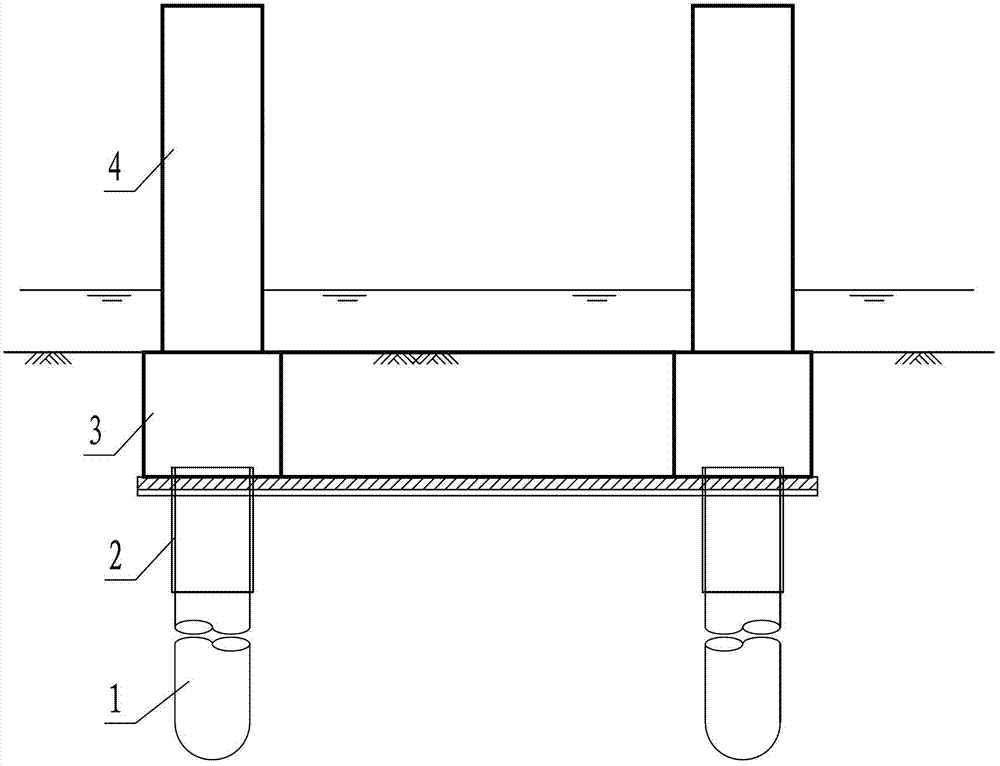

[0023] Such as figure 1 and figure 2 As shown, this embodiment discloses a cast-in-situ pile in a high-concentration salt solution corrosion environment. A steel casing 2 is arranged around the cast-in-place pile body 1 , and the steel casing 2 is used as an additional anti-corrosion component of the cast-in-situ pile body 1 . The steel casing 2 is a cylindrical structure made of steel, and its height extends from the corrosion area of the high-concentration salt solution to the top of the cast-in-situ pile body 1 outside the cast-in-situ pile body 1 . The wall thickness of the steel casing 2 is controlled by the design anticorrosion period, and the anticorrosion effect is highly reliable. Generally, the wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com