Low-yield methanol and higher alcohol fruit wine brewing process

A fruit wine brewing and high-grade alcohol technology, which is applied in the field of fruit wine manufacturing, can solve the problems of aroma component loss, increase of fermentation temperature, rough fruit wine aroma, etc., and achieve the effect of pure wine body, improved product quality and faster clarification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

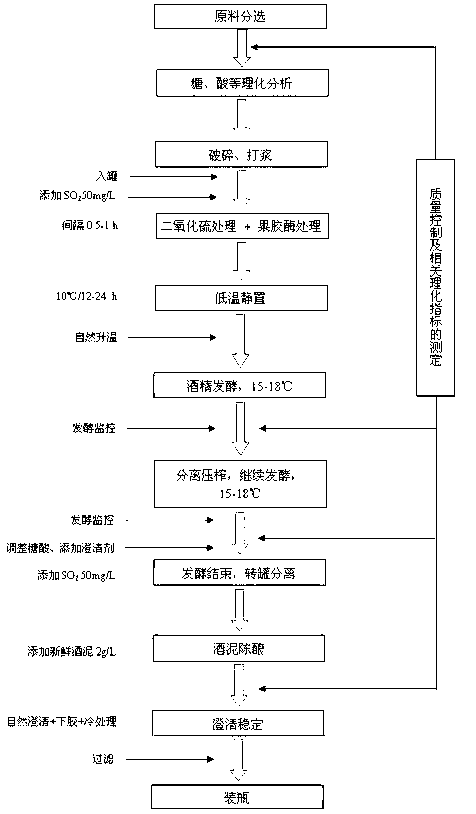

Image

Examples

Embodiment Construction

[0017] The invention integrates a series of fruit wine brewing techniques, reduces the production of higher alcohols in the brewing process, and improves the overall sensory quality of the brewed wine. The specific implementation steps are as follows:

[0018] (1) In the raw material sorting process, unhygienic raw materials are removed, raw material sugar, acid, etc. are tested, and product indicators such as alcohol content and total acid are designed. Different fruit sugar and acid have different requirements, as long as they meet the requirements of normal ripening.

[0019] (2) Fruit crushing and beating should be carried out at <15°C, and the operation should be completed within 1 to 2 hours.

[0020] (3) Add SO in the process of beating into the tank 2 , SO 2 The added amount is 50mg / L, mix well.

[0021] (4) Add 30-50 mg / L of pectinase at an interval of 0.5-1 hour, and mix well.

[0022] (5) After 1 hour, let it stand at 10°C for 12-24 hours.

[0023] (6) Naturall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com