Carrier roller drive device

A technology of transmission device and idler roller, which is applied in the direction of roller table, transportation and packaging, etc. It can solve the problems of geared motor damage, spare parts and capillary scratches, etc., and achieve the effects of improving production efficiency, reducing the number of spare parts and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

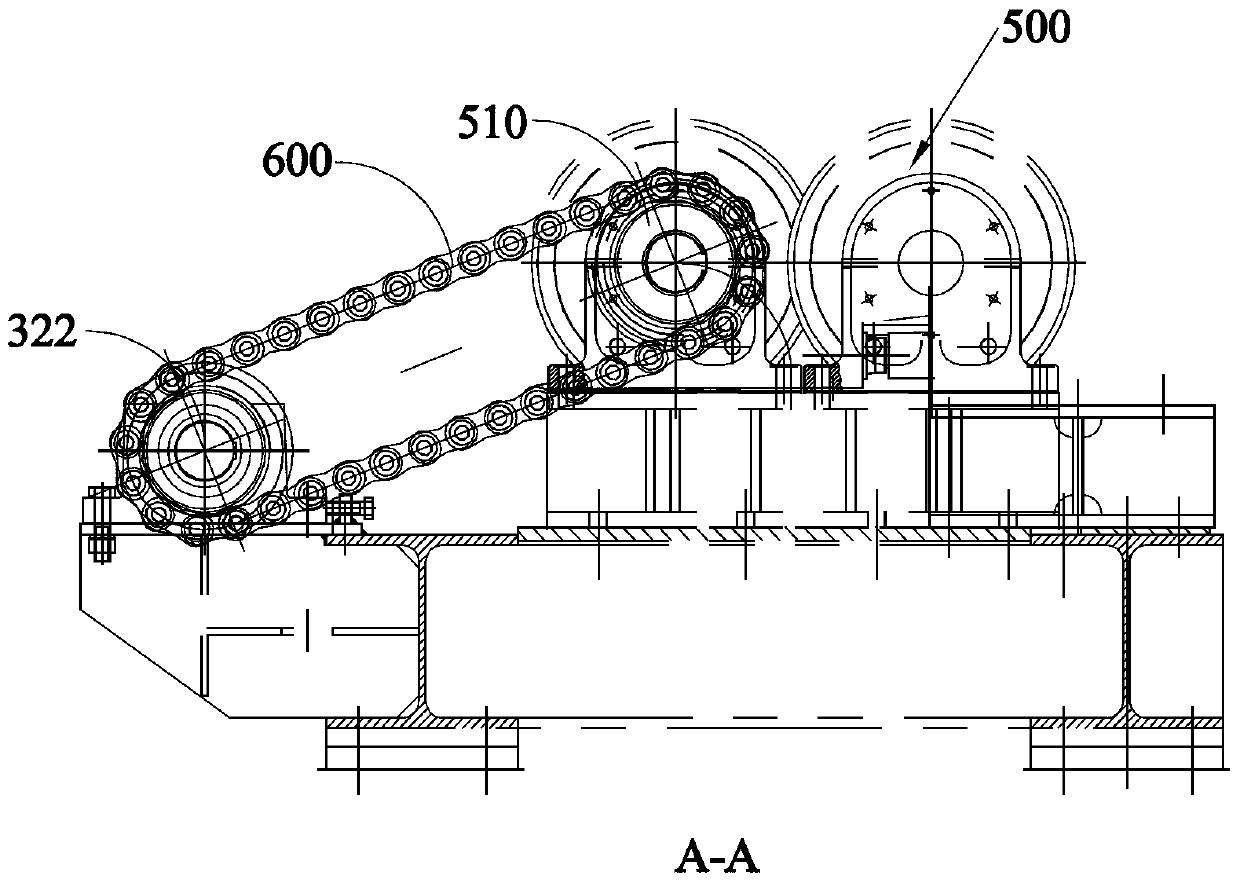

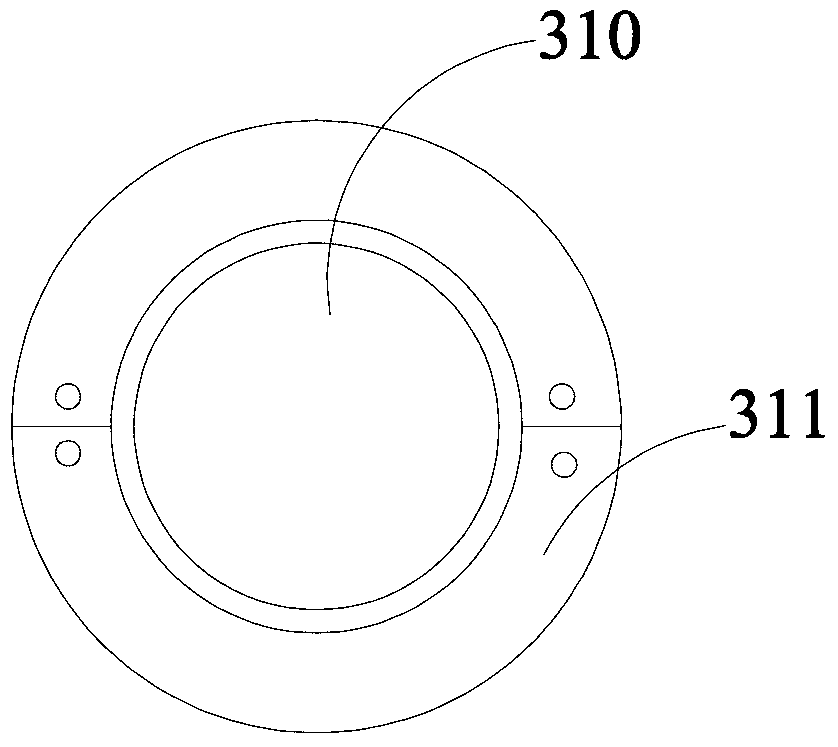

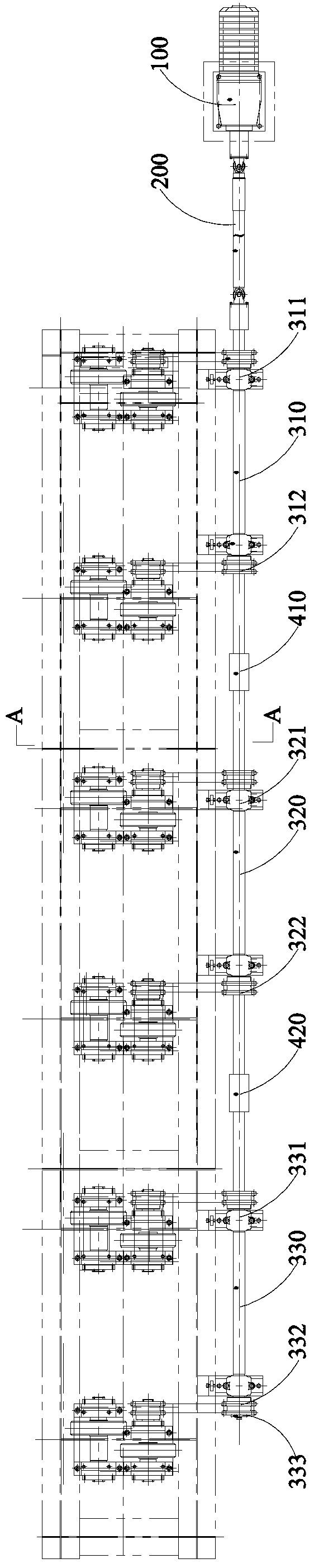

[0018] The invention provides a driving device for idler rollers, comprising: a deceleration motor connected in sequence, a universal coupling and at least two transmission shafts, the transmission shafts are connected by couplings, and each transmission shaft is sleeved with two The bearing seat and two transmission sprockets, the transmission sprocket drives the driven sprocket on the idler roller through the chain. Optionally, the free end of the transmission shaft farthest from the reduction motor is provided with a gland, and the gland fixes a transmission sprocket of the transmission shaft.

[0019] Such as figure 1 and 2 As shown, the present invention will be described in detail by taking a transmission device with three transmission shafts as an example. The idler transmission device includes: a geared motor 100, a universal joint 200, a first transmission shaft 310, a first transmission shaft 410, a second transmission shaft 320, a second transmission shaft 420 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com