A kind of display and bonding method thereof

A technology for displays and substrates, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as poor display effect of displays, and achieve the effect of improving display effect and ensuring the quality of lamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

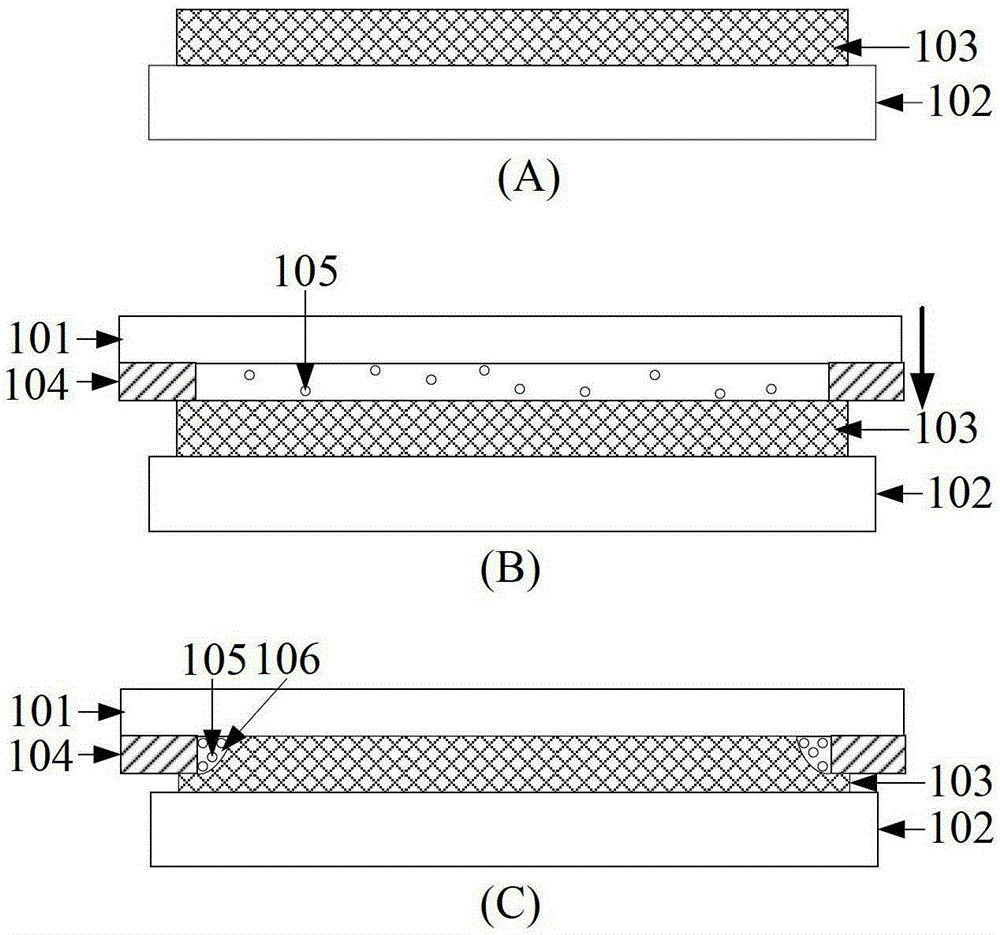

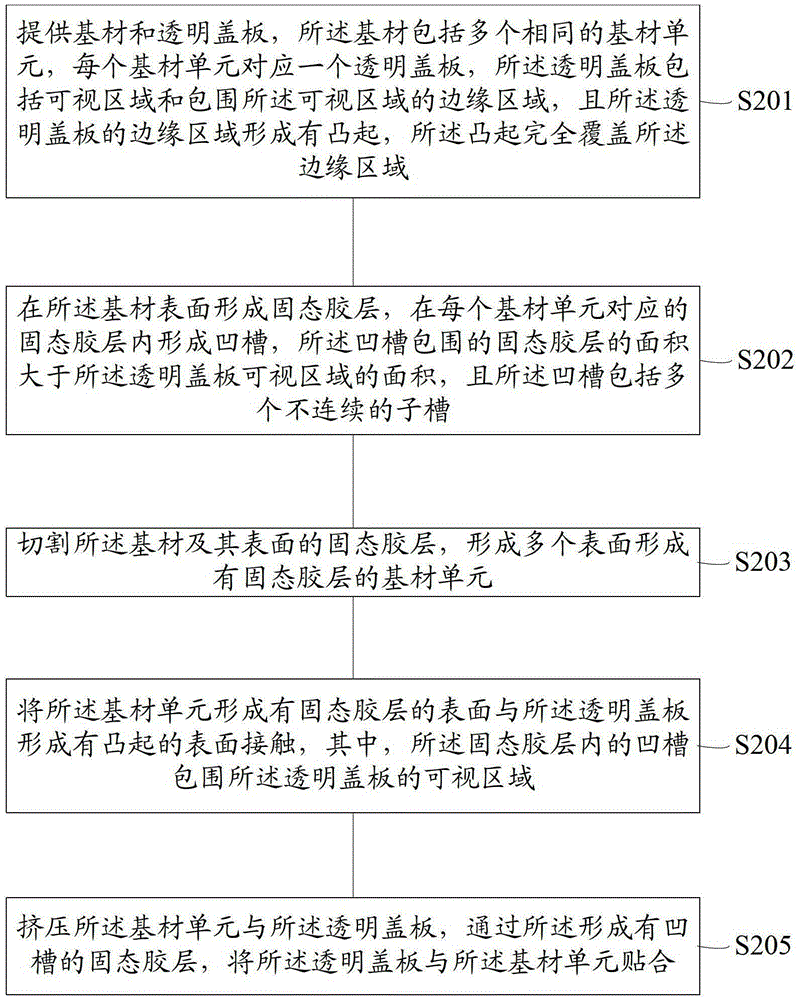

[0037] The flow chart of the bonding method disclosed in this embodiment is as follows figure 2 As shown, Figure 3-Figure 8 This is a schematic diagram of the bonding method provided in this embodiment. The bonding method specifically includes the following steps:

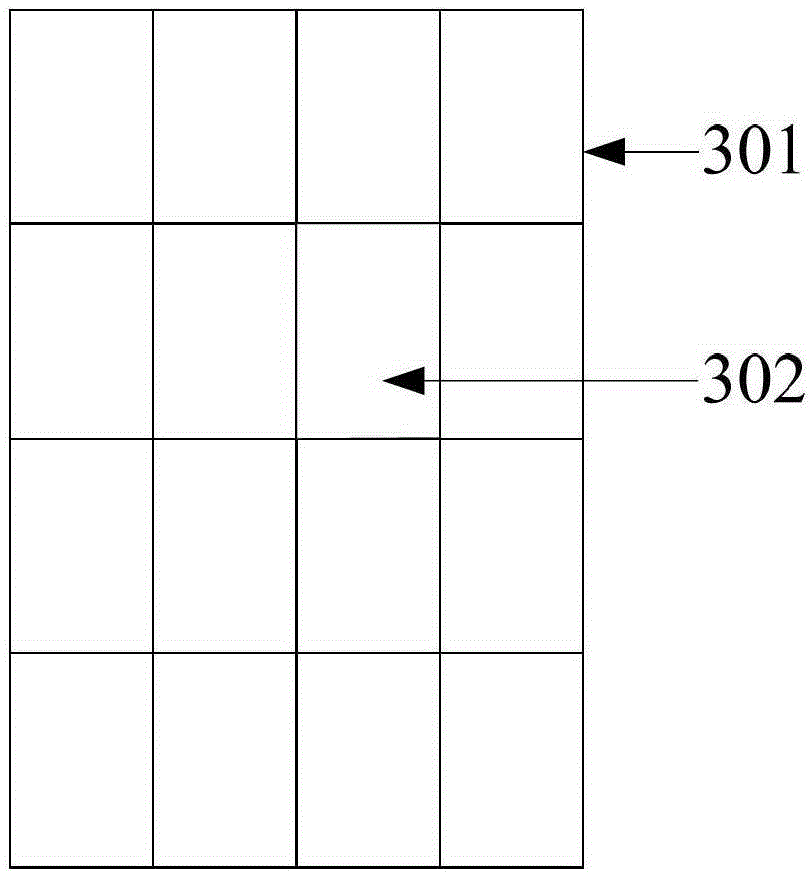

[0038] Step S201: such as image 3 with Figure 4 As shown, a substrate 301 and a transparent cover 303 are provided. The substrate includes a plurality of identical substrate units 302, and each substrate unit 302 corresponds to a transparent cover 303, the transparent cover 303 includes a visible area 304 and an edge area 305 surrounding the visible area, and the edge area 305 of the transparent cover 303 is formed with protrusions 306 that completely cover the edge area 305.

[0039] image 3 A substrate 301 is provided. The substrate 301 includes a plurality of substrate units 302, and the substrate units 302 and the transparent cover 303 are in a one-to-one correspondence, that is, the shape of the substrate unit ...

Embodiment 2

[0055] This embodiment provides a display with integrated touch function. This display is manufactured using the bonding method provided in the first embodiment, wherein the transparent cover is the cover of the display, and the protrusion is formed on The ink on the edge area of the surface to be bonded of the cover plate, and the substrate is the touch function layer of the display.

[0056] The ink is opaque and is used to cover the non-transparent wiring inside the display, and play a role of decorating the display.

[0057] The substrate is used as the touch function layer of the display, and the types of the touch function include: resistive touch function layer, capacitive touch function layer, infrared touch function layer, surface acoustic wave touch function layer, etc. . Wherein, when the touch function layer is a capacitive touch function layer, the touch function layer is preferably an ITO film layer.

[0058] It should be noted that the types of displays with integr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com