High-speed spiral corn-shaped milling cutter for wood

A corn milling cutter, spiral technology, applied in the field of wood cutting processing, can solve the problems of easy appearance of lines on the processing surface, affecting the processing quality, and excessive dust, and achieve the effects of small vibration, improved surface quality, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

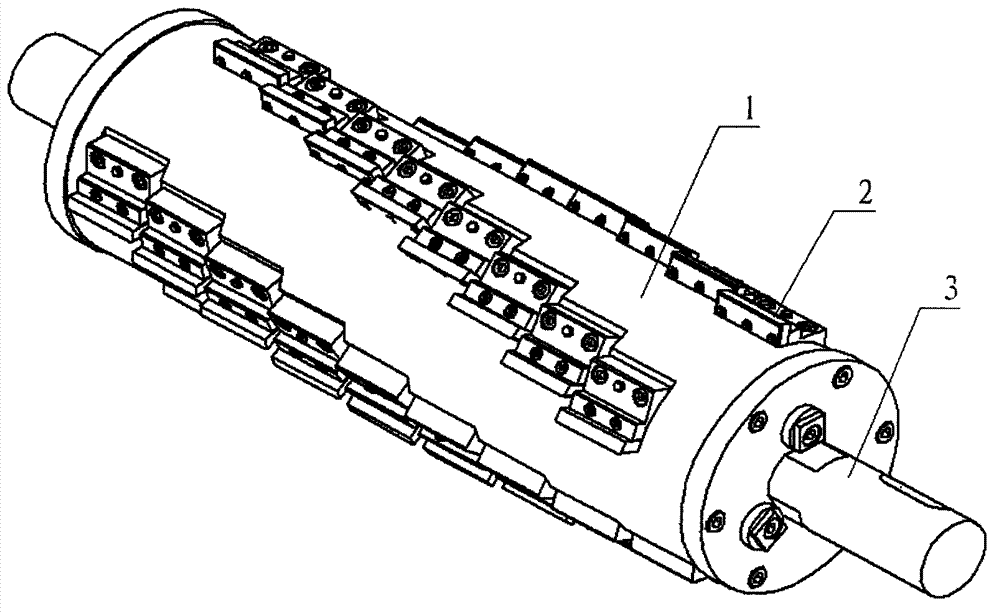

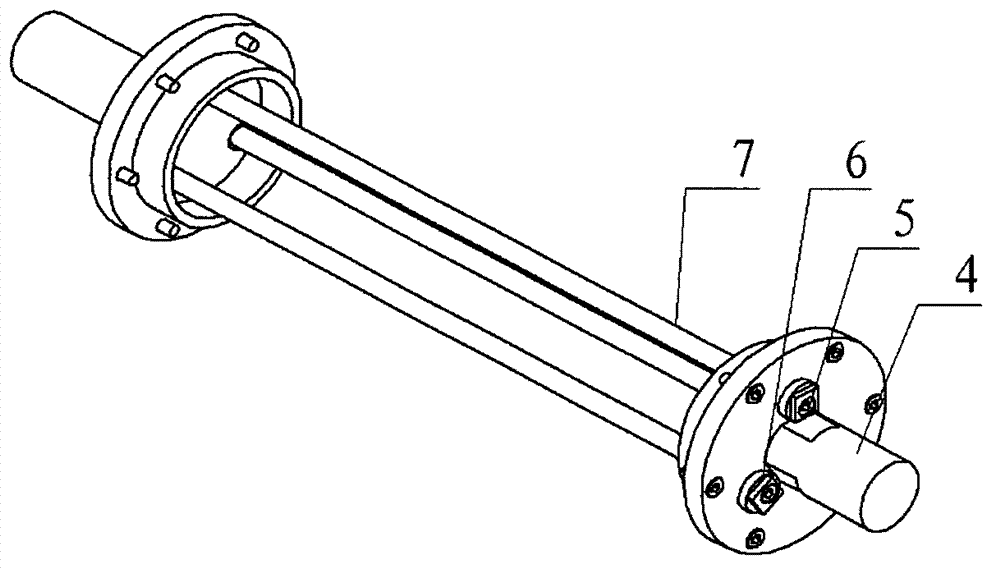

[0023] as attached figure 1 As shown, the present invention provides a high-speed spiral corn milling cutter for wood. The corn milling cutter includes a cutter body 1, a cutter 2 and a counterweight end cover 3. The cutters are arranged like "corn", and the cutter adopts a combined structure, which is convenient for assembly. dismantle.

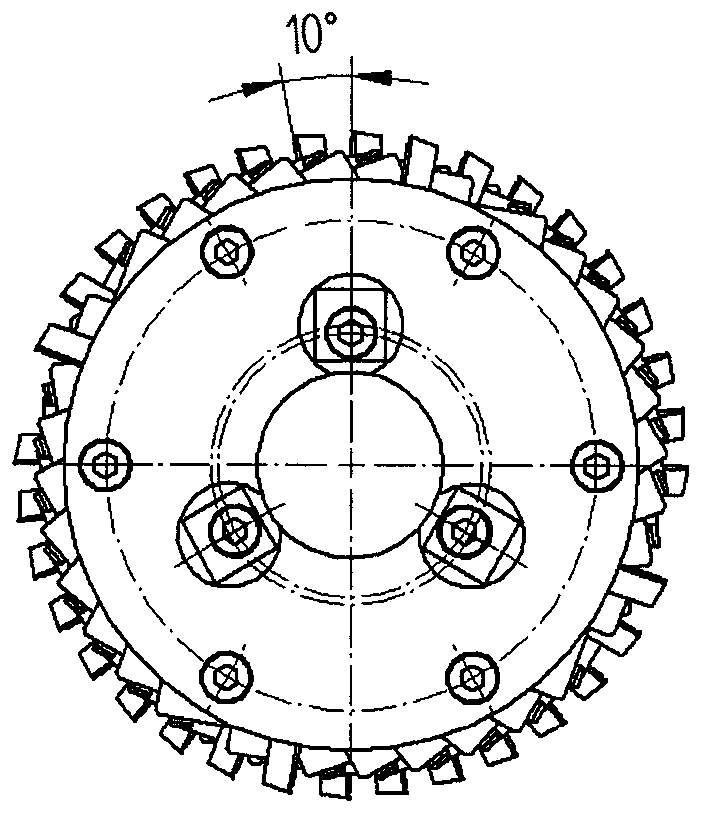

[0024] The diameter at the tip of the corn milling cutter is designed to be φ180mm, the diameter of the cutter body is φ150, the cutter body is 15mm exposed, the cutter rotation speed is 5000rpm, and the corresponding cutting line speed is 2800m / min, which is in the high-speed cutting area; the cutter width is designed as 450mm, wide adaptability to the milling width of common wood.

[0025] The blade 1 has 4 rows of spiral grooves evenly distributed along the circumference, and the step width in the spiral grooves is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com