Laser welding method for medium steel plates

A technology of laser welding and thick steel plates, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the weld seam cannot meet the design requirements and can not achieve one-time welding completion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

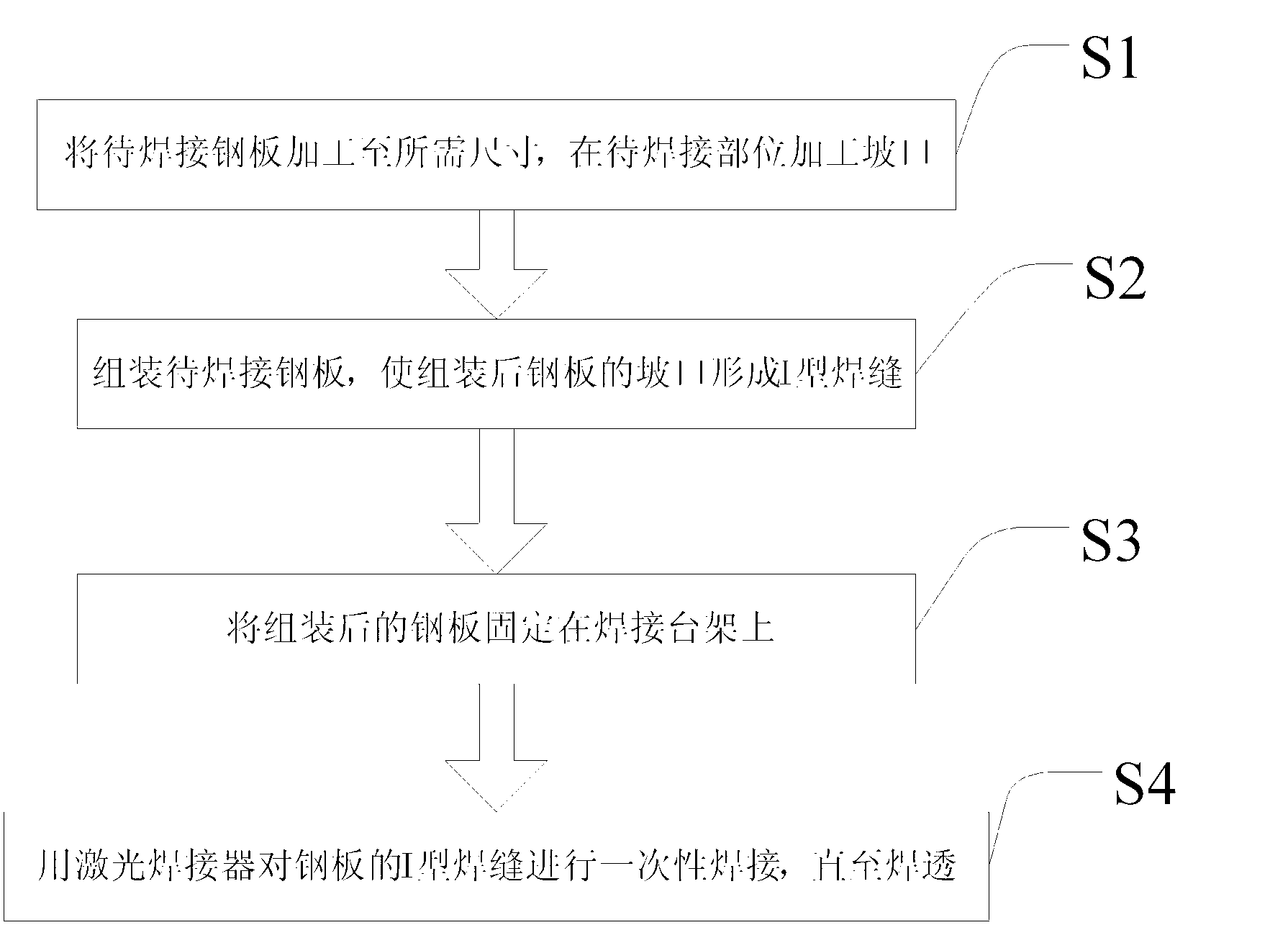

[0019] The specific implementation of the laser welding method for medium and thick steel plates of the present invention will be described in detail below in conjunction with the accompanying drawings.

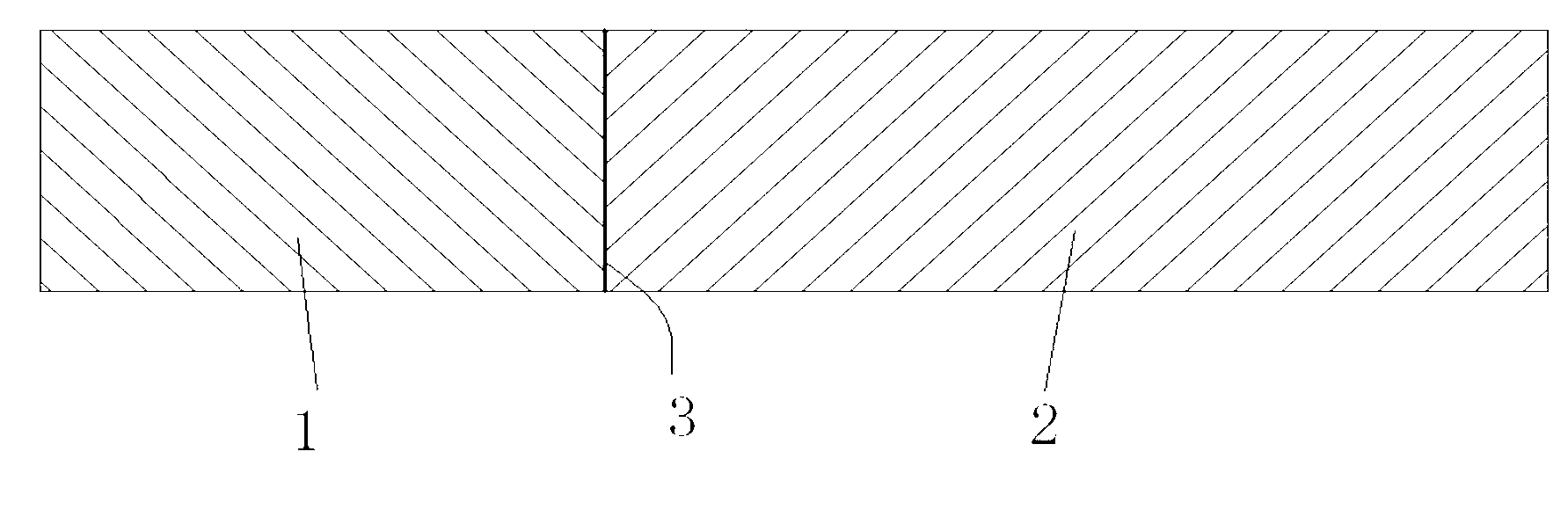

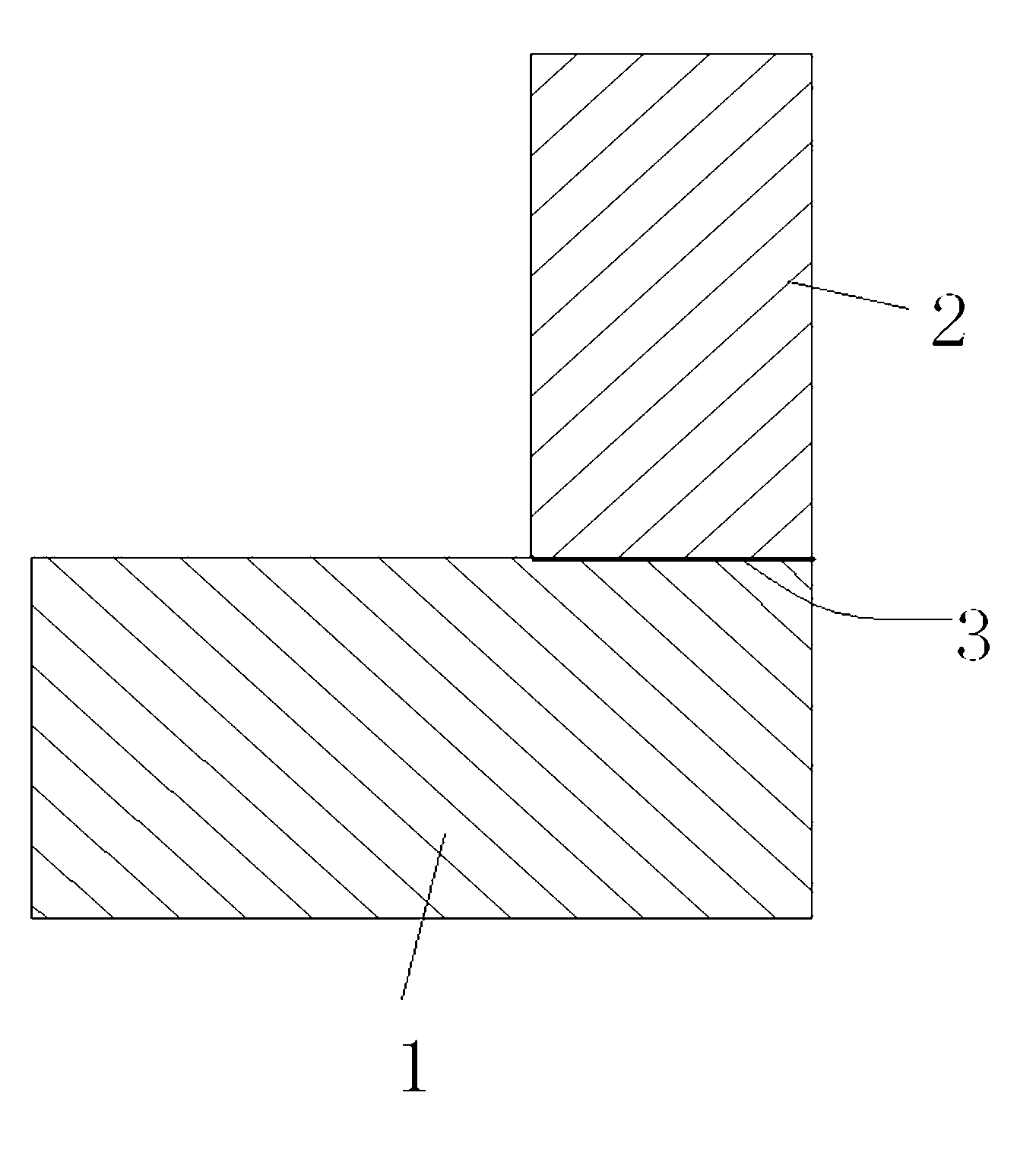

[0020] See attached figure 1 , 2 , 3. The thickness of the medium-thick steel plate is 5-18mm. The two steel plates 1 and 2 should be butt jointed or angled into a typical finished product as shown in the figure. The welding method is as follows:

[0021] Step 1: Process the steel plates 1 and 2 to be welded to the required size, and process grooves on the parts to be welded (step S1 in the figure), and design different butt joints or fillet joints of the grooves according to different conditions of the steel plates to be welded Form (such as stepped joints, oblique butt joints, bottom-lock self-centering joints, etc.).

[0022] Step 2: Assemble the steel plates 1 and 2 to be welded so that the groove of the assembled steel plates forms an I-shaped weld 3 (step S2 in the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com