Servo direct-drive type incremental rolling forming process for cylindrical piece with teeth inside and outside

A roll forming, direct drive technology, applied in the field of servo direct drive incremental roll forming technology, can solve the problems of poor filling quality of tooth profile, complex process system, low processing efficiency, etc. Simple system and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

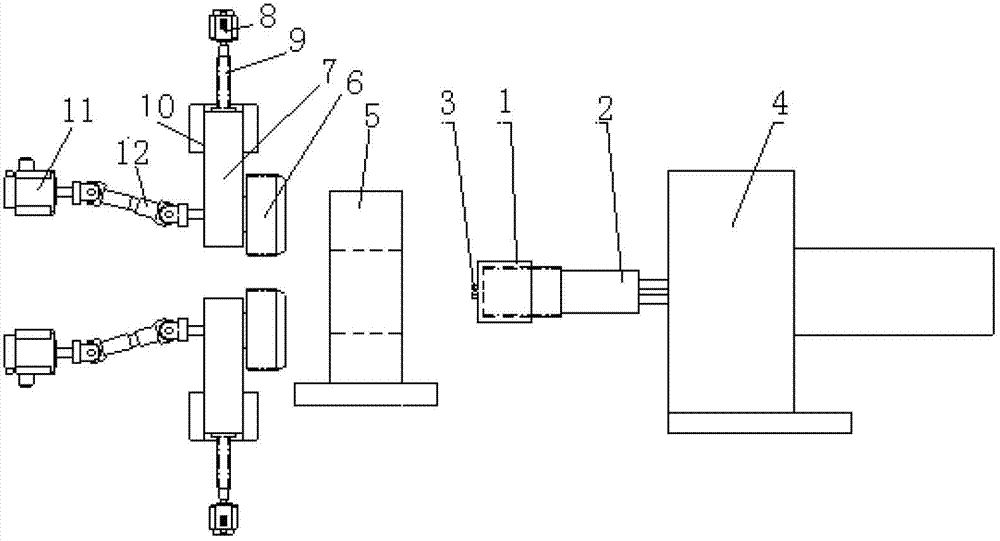

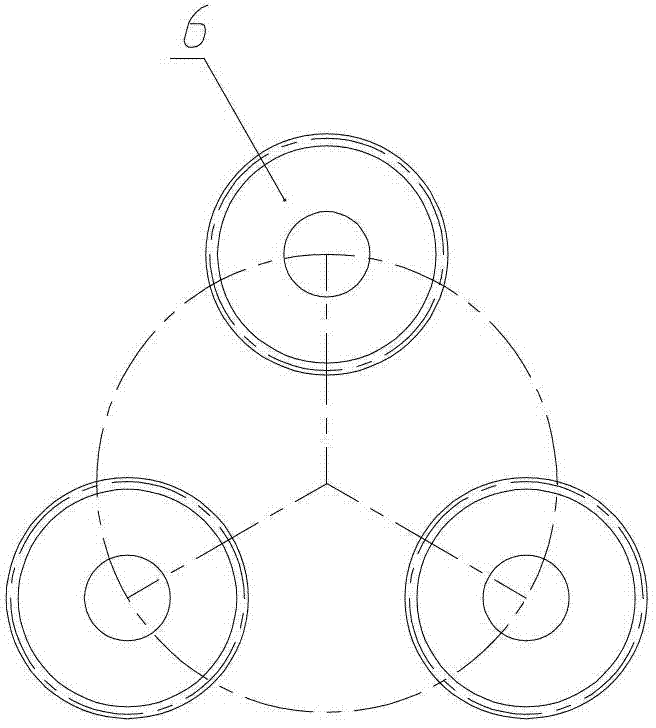

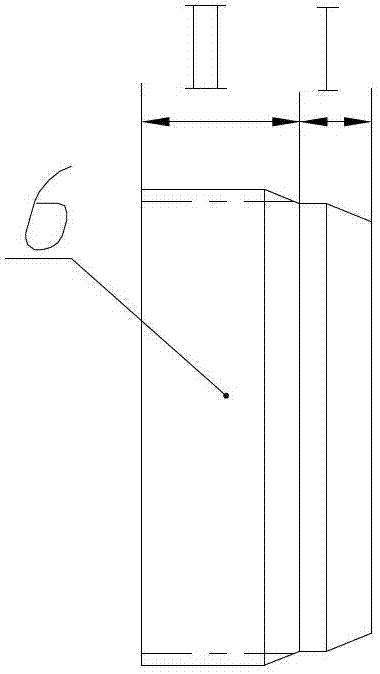

[0024] refer to figure 1 , the device for realizing the process of the present invention includes a mandrel 2 and a compound AC servo motor 4, the blank 1 is fixed on the mandrel 2 by fastening screws 3, the mandrel 2 is connected with the compound AC servo motor 4, and the layout of the medium and high frequency induction heater 5 In front of the composite AC servo motor 4 and behind the medium-high frequency induction heater 5, three rolling dies 6 are evenly distributed along the circumference of the blank 1 axis. The lever nut pair 9 is connected to the adjusting AC servo motor 8, and the rear of the rolling die 6 is connected to the main power AC servo motor 11 through a universal coupling 12.

[0025] A servo direct drive incremental roll forming process for inner and outer toothed cylindrical parts, comprising the following steps:

[0026] a)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com