Energy-saving and synergizing wet desulfurization catalyst and using thereof

A wet desulfurization and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, separation methods, etc., can solve equipment fouling and blockage, easy foaming of desulfurization slurry, gypsum Dehydration is difficult and other problems, to achieve good catalytic performance, promote the effect of limestone dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

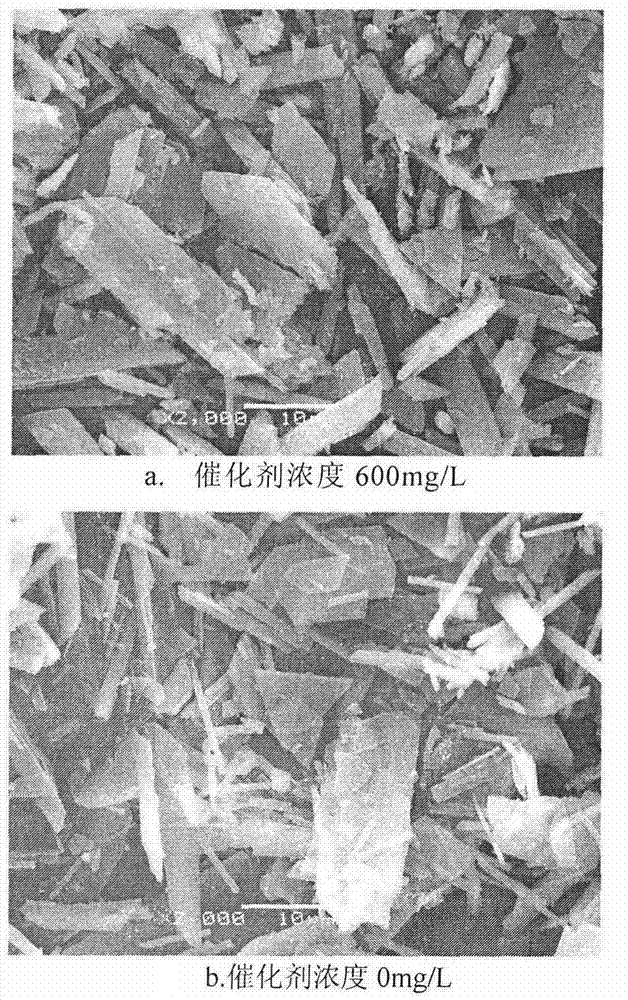

Embodiment example 1

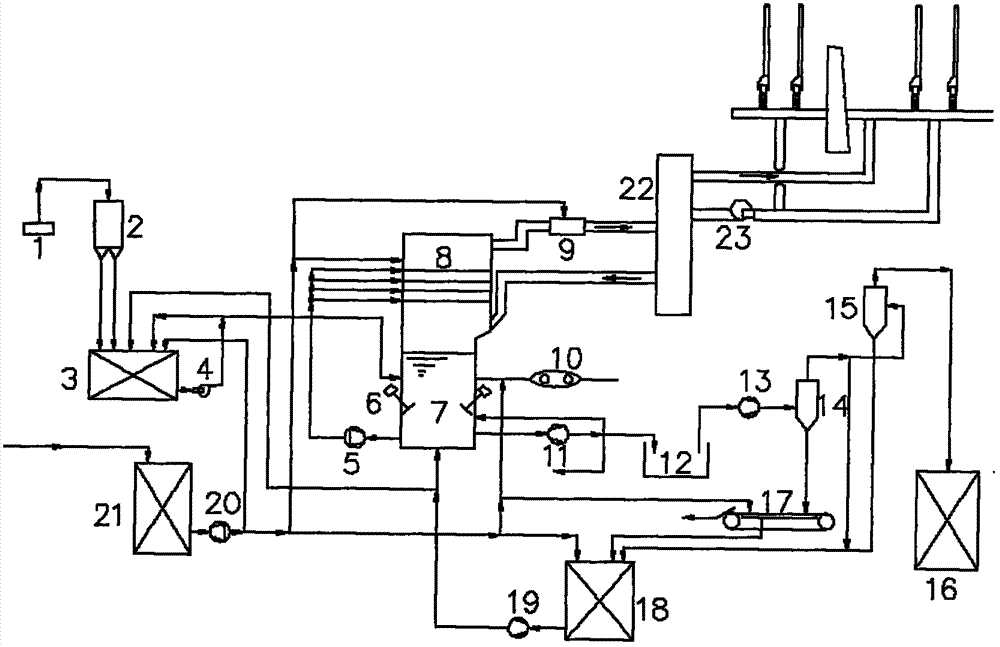

[0028] The process flow of the test device is attached image 3 As shown, it includes flue gas system, desulfurization tower, gypsum dehydration and treatment system, absorbent preparation and delivery system, etc. Simulated flue gas from liquefied SO2 A mixture of cylinder gas and air. Air is introduced by blower, SO 2 It is controlled by adjusting the pressure reducing valve and the gas flow meter, and then the flue gas temperature is heated to the required fixed value by the electric heater. The desulfurization tower is a cylindrical structure, made of stainless steel, the height of the tower is 10.8m, the diameter of the tower is 0.8m, and the section of the flue gas inlet flue is 195×210mm 2 The rectangular shape enters the spray tower, and three layers of spiral nozzles are respectively installed at the heights of 5.3m, 6.5m, and 7.7m in the tower, with the nozzles facing downward. Two-stage mist eliminators are installed at heights of 8.6m and 10.2m respectively, and...

Embodiment example 2

[0032] The application site is the No. 1 desulfurization unit of a Sinopec Co., Ltd. The device adopts limestone / gypsum wet desulfurization process, the diameter of the absorption tower is 6.2m, the height is 30.18m, the liquid level of the absorption tower is 6.8-7.0m during normal operation, and the volume of the slurry pool is 211m 3 , the boiler capacity corresponding to treatment is 220t / h, and the flue gas treatment capacity is 291646Nm 3 / h. Operating pH = 4.8-5.6, the slurry density of the absorption tower is maintained at 1080-1125kg / m 3 , a total of 3 slurry circulation pumps A / B / C (rated power 90kW, 90kW, 90kW, voltage 380V), 24 nozzles are arranged in a single spray layer, and the slurry spray volume is 930m 3 / h. Boiler combustion raw flue gas SO 2 The concentration is 2100mg / Nm 3 , the capacity of the oxidation fan of the system is obviously insufficient, and the desulfurization efficiency drops sharply to above 85%. In serious cases, the system cannot dehyd...

Embodiment example 3

[0036] This test plans to choose the 3# desulfurization device of a Sinopec Co., Ltd., the system adopts the limestone / gypsum wet desulfurization process, the diameter of the absorption tower is 10m, the height is 26.1m, and the liquid level of the absorption tower is 6.0-7.0m during normal operation. The boiler capacity is 3×220t / h, when running at full load: the standard dry flue gas flow rate is 927069Nm 3 / h, the particle size of limestone is 250 mesh and 90%, and the consumption of limestone is ≤2.75t / h. After the flue gas is in full contact with the top-down circulating slurry countercurrent in the absorption tower, the SO in the flue gas 2 Dissolved in limestone / gypsum slurry and absorbed, most of the smoke is intercepted and enters limestone / gypsum slurry. The washed flue gas leaves the absorption tower through the demister, returns to the net flue gas connection of the steel flue through the flue outlet baffle, and is discharged through the chimney. Operating pH=4.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com