Magnesium aluminate spinel-supported sulphur-tolerant methanation catalyst

A sulfur-resistant methanation, magnesium-aluminum spinel technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of insufficient reaction stability and reaction catalytic activity decline, shortened catalyst life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

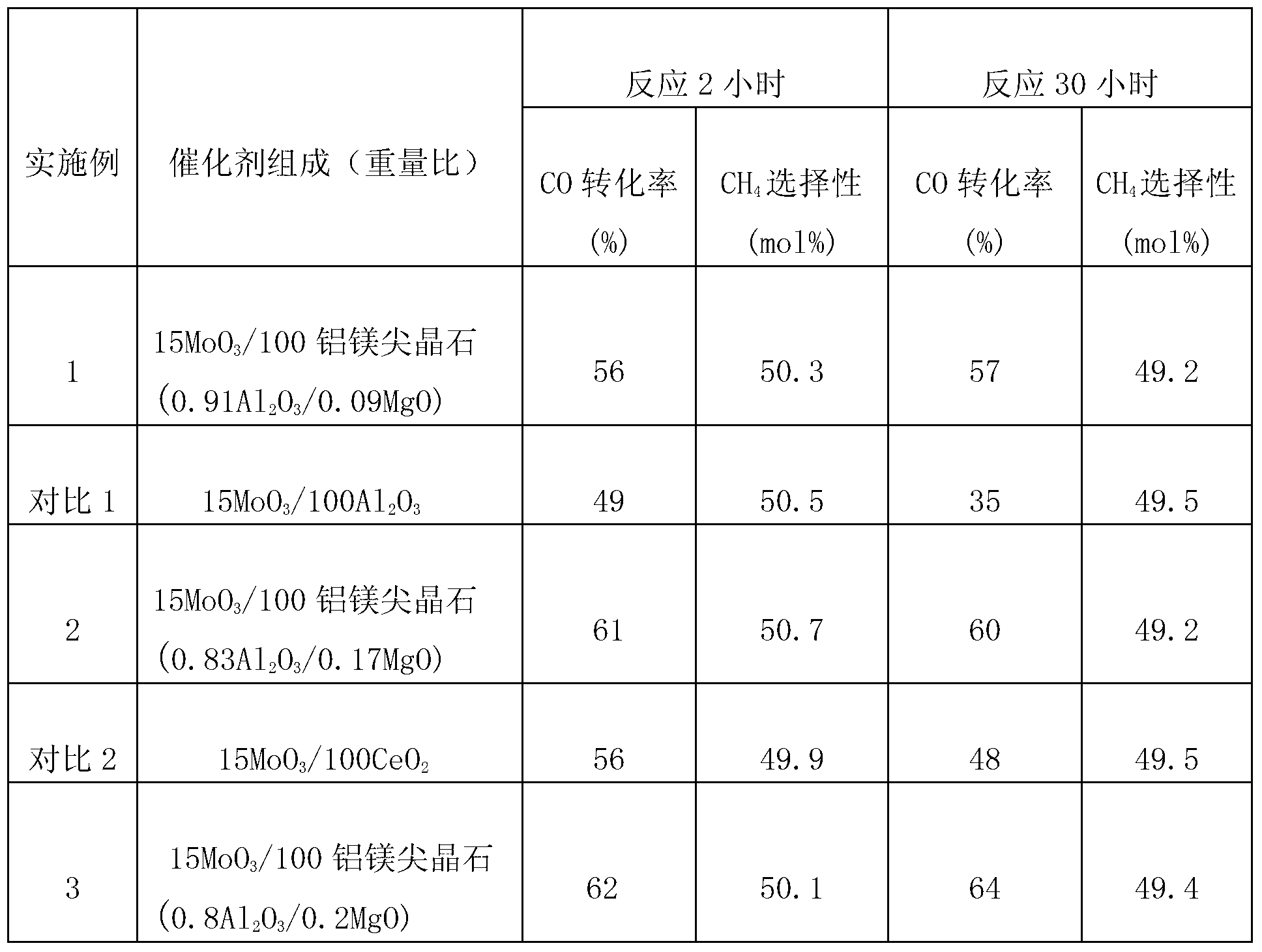

[0092] Example 1: Preparation of 15MoO 3 / 100 Al-Mg spinel (0.91Al 2 o 3 / 0.09MgO) catalyst

[0093] Step (1): Preparation of 91Al by co-precipitation method 2 o 3 -9MgO aluminum magnesium spinel porous support

[0094] 311.4 g Al(NO 3 )3 9H 2 O and 32.1 g Mg(NO 3 ) 3 ·6H 2 Dissolve O together in 500 ml of deionized water to form a mixed solution. Add the mixed solution and ammonia water with a concentration of 3 mol / L into the beaker under vigorous stirring at 70°C, keep the pH value at about 11, and react until the precipitation is complete. After static aging for 2 hours, the precipitate was filtered, washed three times with deionized water, and the obtained filter cake was dried in an oven at 120° C. for 12 hours to obtain a dry powder. The above dry powder was calcined in a muffle furnace at 700 °C for 2 hours to obtain 91Al 2 o 3 / 9MgO Al-Mg spinel porous carrier, its specific surface area measured by BET is 235m 2 / g. Step (2): Preparation of 15MoO 3 / 100...

Embodiment 2

[0098] Embodiment 2: Preparation of 15MoO 3 / 100 Al-Mg spinel (0.83Al 2 o 3 / 0.17MgO) catalyst

[0099] Step (1): Preparation of 83Al by co-precipitation method 2 o 3 -17MgO aluminum magnesium spinel porous carrier

[0100] In addition to Mg(NO 3 ) 3 ·6H 2 The amount of O is changed from 32.1 grams to 64.2 grams, and the step (1) in Example 1 is repeated to obtain 83Al 2 o 3 -17MgO Al-Mg spinel porous carrier, the BET specific surface area is 213m 2 / g.

[0101] Step (2): Preparation of 15MoO 3 / 100 Al-Mg spinel (0.83Al 2 o 3 / 0.17MgO) catalyst

[0102] Repeat step (2) in Example 1 to obtain 15MoO 3 / 100 Al-Mg spinel (0.83Al 2 o 3 / 0.17MgO) sulfur-resistant methanation catalyst, its specific surface area measured by BET is 197m 2 / g.

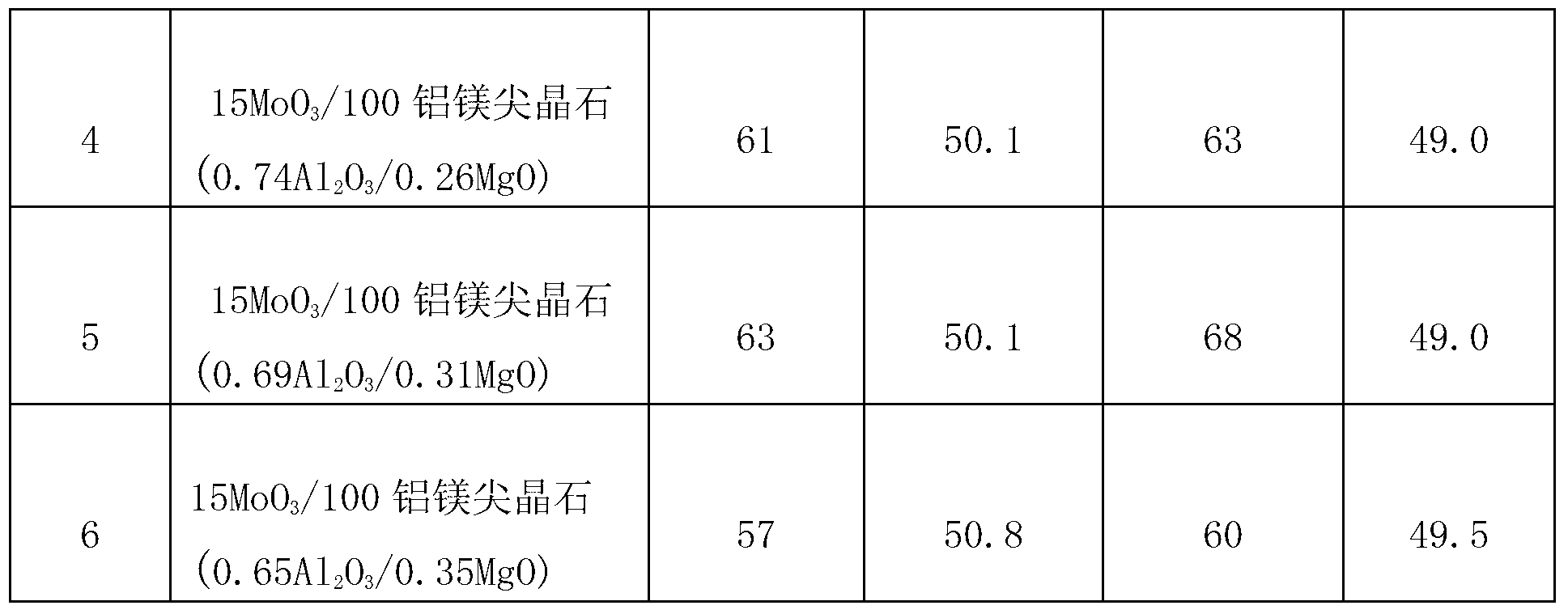

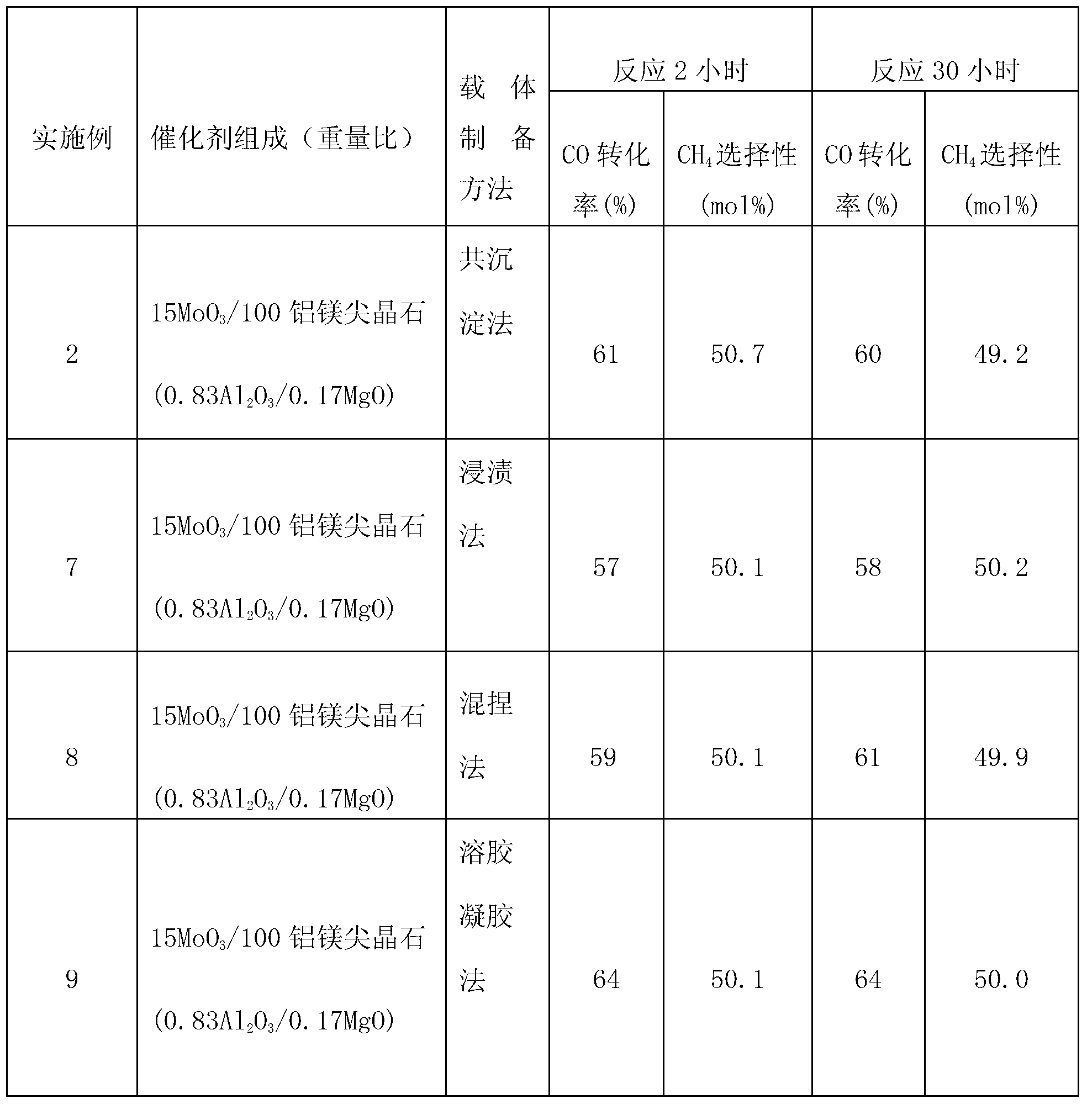

Embodiment 7

[0121] Example 7: Preparation of 15MoO 3 / 100 Al-Mg spinel (0.83Al 2 o 3 / 0.17MgO) catalyst

[0122] Step (1): Preparation of 83Al by impregnation method 2 o 3 -17MgO aluminum magnesium spinel porous carrier

[0123] 53.8 g Mg(NO 3 ) 3 ·6H 2 O was dissolved in 80 mL of deionized water to form a solution. Weigh 42 grams of alumina powder (commercial Sasol product, specific surface area is 200m 2 / g), then add alumina powder into the above solution and stir vigorously, evaporate the water to dryness, put it in a drying oven at 110°C for 16 hours, and finally bake it in a muffle furnace at 700°C for 2 hours to obtain 83Al 2 o 3 / 17MgO Al-Mg spinel porous carrier, its specific surface area measured by BET is 175m 2 / g.

[0124] Step (2): Preparation of 15MoO 3 / 100 Al-Mg spinel (0.83Al2 o 3 / 0.17MgO) catalyst

[0125] Repeat the process of step (2) in Example 1 to obtain 15MoO 3 / 100 Al-Mg spinel (0.83Al 2 o 3 / 0.17MgO) sulfur-resistant methanation catalyst, its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com