Thermal pressure relief device with expansion activation

一种泄压、设备的技术,应用在热泄压设备(TPRD)领域,能够解决单向形状记忆触发机构昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following detailed description and drawings describe and illustrate various exemplary embodiments of the invention. The description and drawings are intended to enable a person skilled in the art to make and use the invention and are by no means intended to limit the scope of the invention.

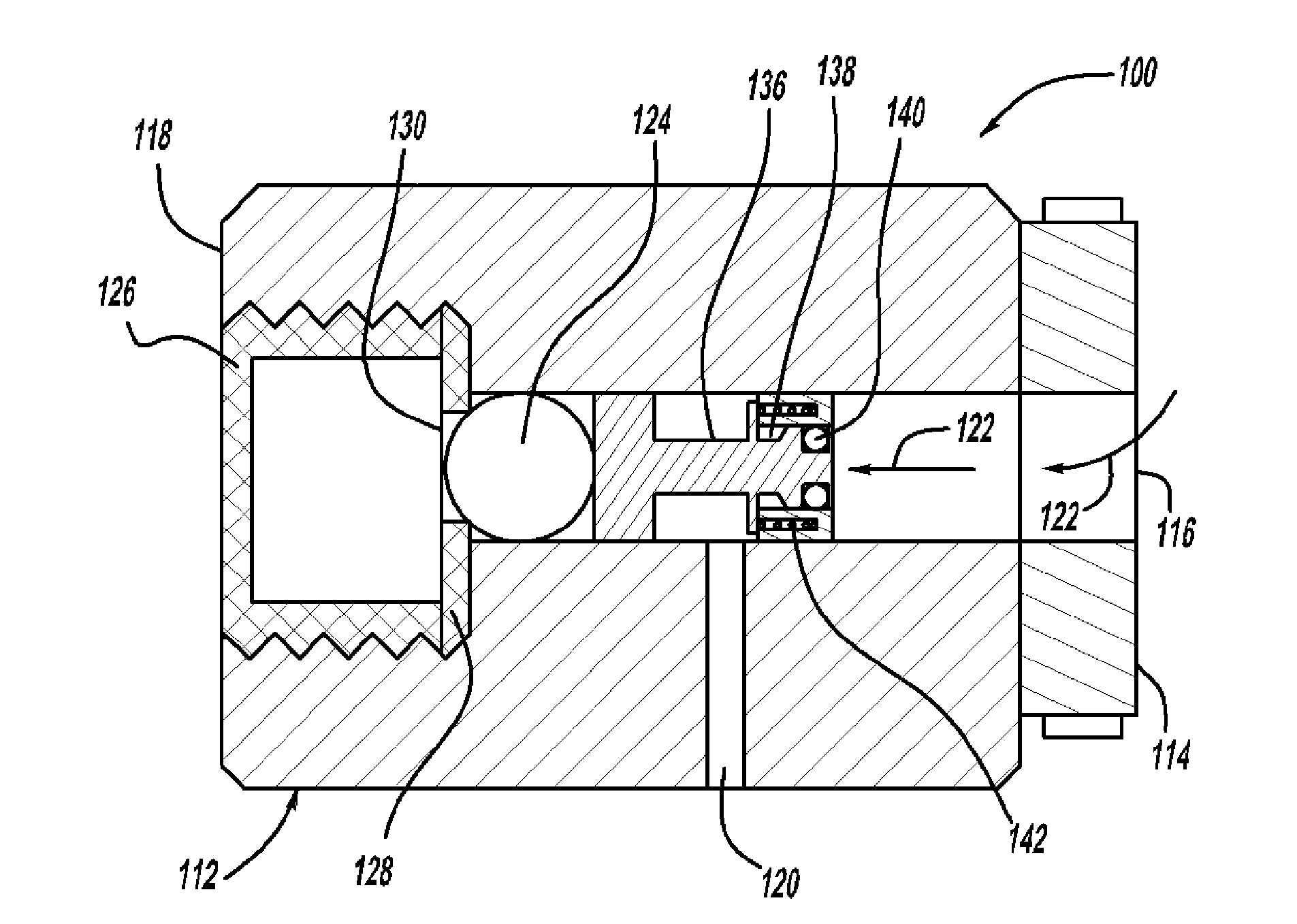

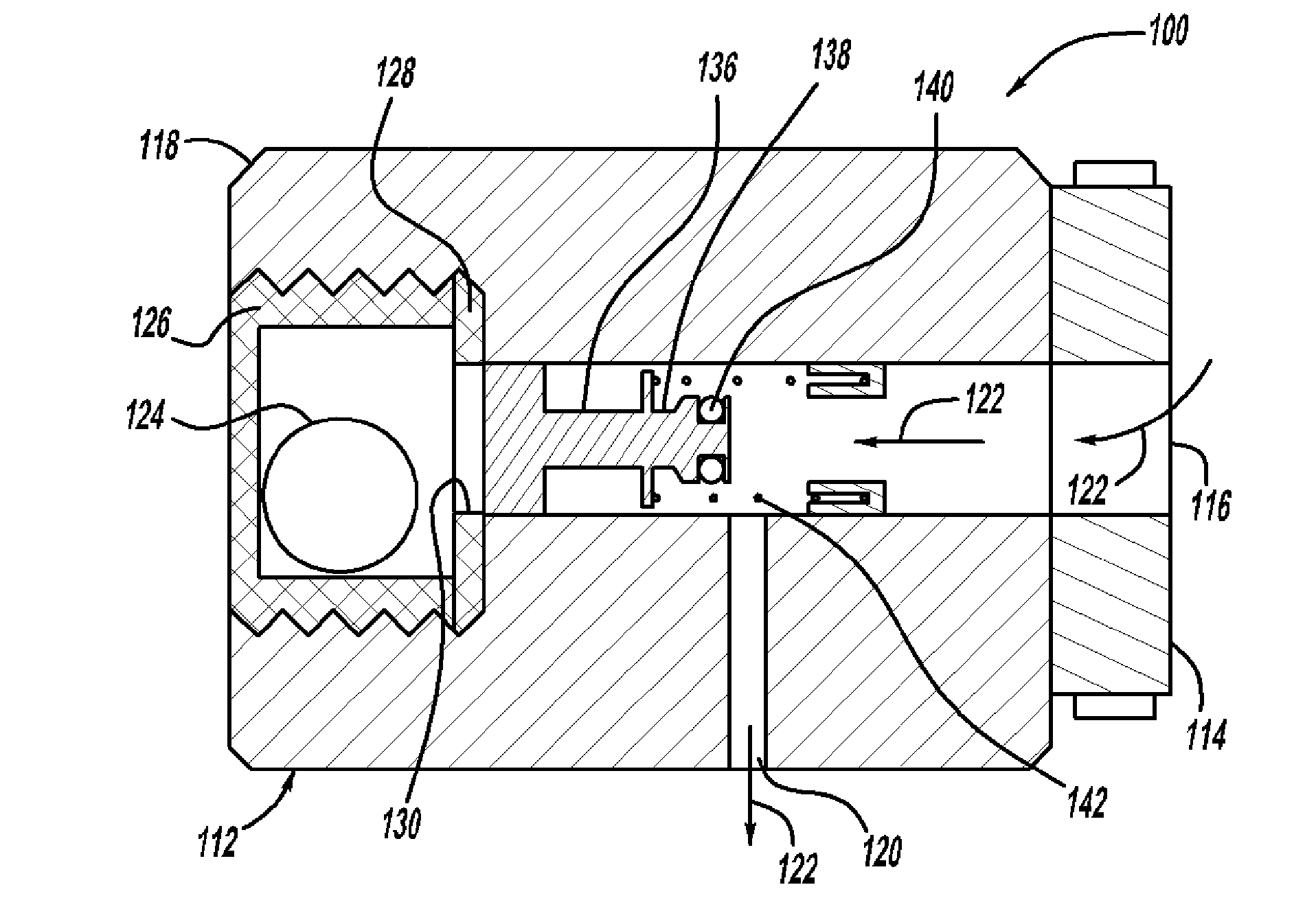

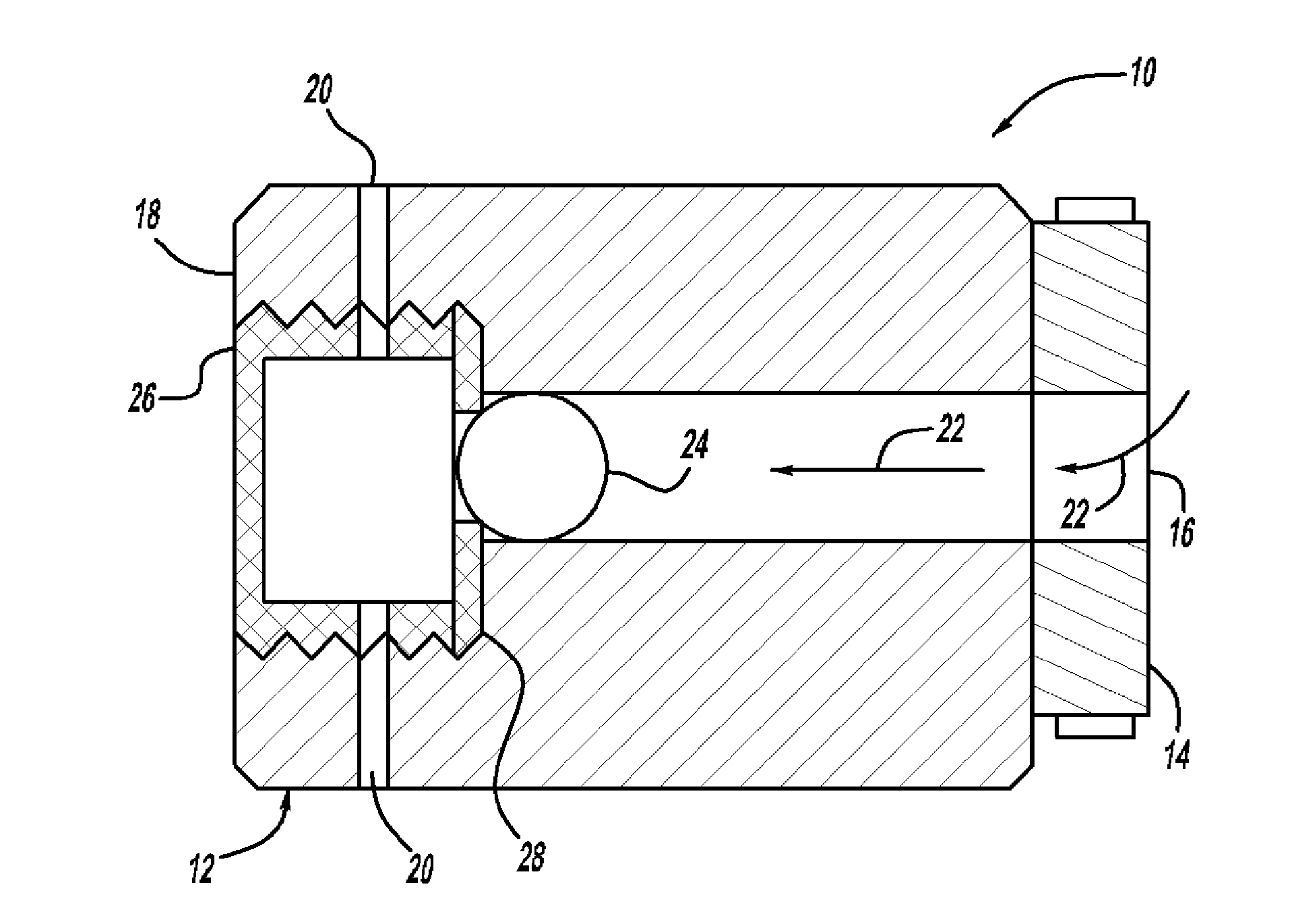

[0049] In FIGS. 1 and 2 , a thermal pressure relief device (TPRD) 10 is shown comprising a housing 12 having a first end 14 with a first aperture 16 and a second end with a second aperture 20 18. First aperture 16 and second aperture 20 are configured to allow fluid 22 to flow through housing 12 . In one example, when the TPRD is activated as shown in FIG. 2 , fluid 22 may flow from a high pressure vessel (not shown) in fluid communication with first aperture 16 through housing 12 and second aperture 20 to the ambient atmosphere. Housing 12 may, for example, be configured to be threadably engageable with a high-pressure vessel.

[0050] TPRD 10 includes a trigger member 24 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com