Jet packer ground simulation method applicable to multilevel hydraulic jet fracturing

A technology of hydrojet and ground simulation, applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve the problems of increasing labor intensity, prolonging the construction period, increasing the number of tool replacements, etc., and reducing the number of replacements The effect of reducing the number of tools, reducing the safety risk of well control, and shortening the construction period

Active Publication Date: 2013-07-03

CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the prior art, there is no ground simulation test method for the multi-stage hydraulic jet isolation tool, which leads to the inability to correctly obtain the sealing performance of the isolation tool. Therefore, the number of tripping and replacement tools will increase, which increases the labor cost. strength, prolonging the construction period, and correspondingly increasing well control safety risks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

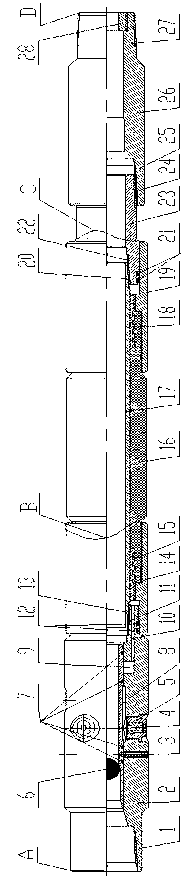

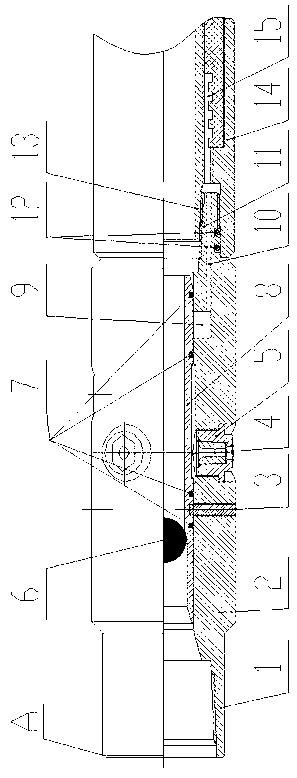

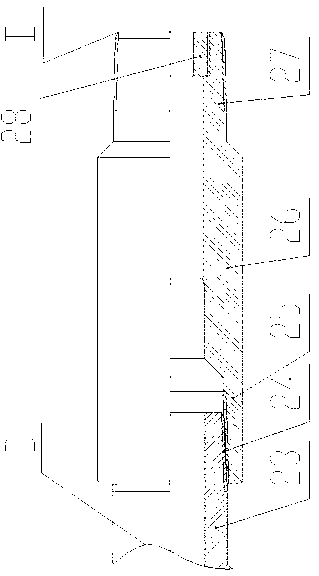

The invention discloses a jet packer ground simulation method applicable to multilevel hydraulic jet fracturing. The method comprises the following steps: a, connecting in series jet packers of corresponding amount and other required tools on a construction test string according to the required designed level amount of an oil well and a gas well, placing a steel ball in an inlet of the construction test string, and connecting a high-pressure pipeline; b, gradually increasing the discharge capacity, if a sliding sleeve is hit off by the steel ball and pushed to pass through a central pipe of the packer continually and enter a sliding sleeve standing joint connected onto the lower part of the packer, and a water hole of a spray gun normally jets water, performing next-level test for the jet packer; c, if the sliding sleeve is not hit off by the steel ball, checking the mounting position of the sliding sleeve and the gap between the sliding sleeve and the spray gun, checking the position of a shear pin, and performing the test and detection in step b; and repeating steps a, b and c until completing all set tests. With adoption of the method, opening of all packers and jet tools, and jet of the spray gun can be observed.

Description

technical field The invention relates to a ground simulation method for an isolation jet tool suitable for multi-stage hydraulic jet fracturing, which is used for well completion stimulation measures in the oil and gas drilling process, and relates to the technical field of ground detection of acid fracturing tools. Background technique Hydrojet segmental modification is the product of the combination of hydrojet and fracturing technology, involving perforation and fracturing stimulation measures; one string can be used to realize multi-stage construction in horizontal wells, and it can be used in open holes, cement-consolidated casings, and unconsolidated casings. Fracturing is carried out under various completion methods such as knotted screen pipes, and the construction efficiency can be greatly improved. Among the prior art, the following patent applications are related to packer technology: The publication number is CN102650202A, and the Chinese patent document publi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B47/117E21B43/26E21B33/12

Inventor 邓小强张波陈万林韩虎成许建伟张文杨文明张海涛柳瑞军张敏

Owner CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com