Hydraulic jet packer applicable to multilevel hydraulic jet fracturing

A technology of hydraulic jetting and tools, applied in the directions of sealing/packing, production fluid, wellbore/well components, etc., can solve problems such as packer failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

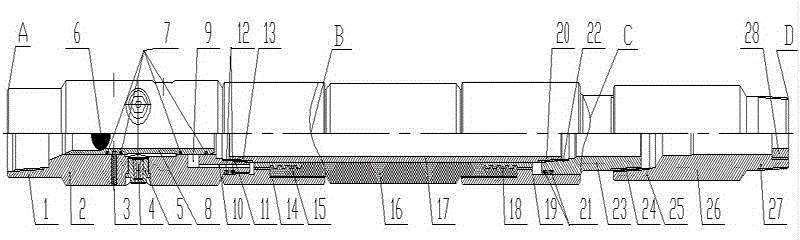

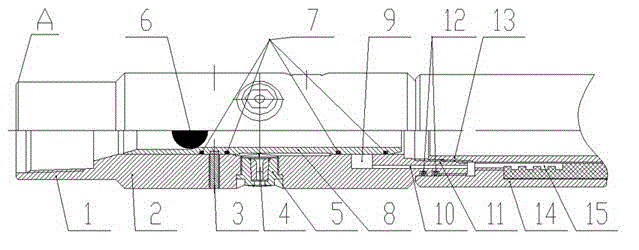

[0032] As a preferred embodiment of the present invention, the present invention includes a spray gun, a packer and a sliding sleeve seating joint, one end of the packer is connected to the spray gun, the other end of the packer is connected to the sliding sleeve seating joint, and a sliding sleeve is arranged in the spray gun , the inner diameter of the sliding sleeve is variable, from the spray gun to the direction of the joint where the sliding sleeve is located, the inner wall of the sliding sleeve is composed of three sections with successively smaller inner diameters, and a ball seat is arranged inside the sliding sleeve. In specific applications, the specifications of the three inner diameters that become smaller in turn are: 28mm, 32mm and 35mm.

Embodiment 2

[0034] As another preferred embodiment of the present invention, the outer wall of the spray gun is provided with scissors, and the outer wall of the sliding sleeve is provided with a scissor slot matching with the scissors, and the sliding sleeve is fixed to the spray gun via the scissors. All the other are with embodiment 1.

Embodiment 3

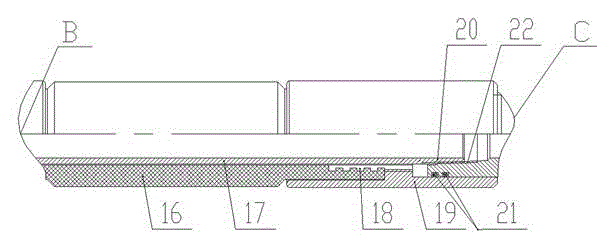

[0036] As another preferred embodiment of the present invention, the spray gun includes a spray gun body and a nozzle arranged on the spray gun body, the sliding sleeve is arranged in the inner cavity of the spray gun, and the sliding sleeve and the inner cavity of the spray gun are connected by a transition fit; the sliding sleeve The sleeve seating joint includes the upper end of the sliding sleeve seating joint, the lower end of the sliding sleeve seating joint and the baffle of the sliding sleeve seating joint; the packer includes a rubber sleeve and a center pipe arranged in the rubber sleeve, and the upper end of the rubber sleeve is connected to the upper rubber sleeve seat. The lower end of the rubber cartridge is connected to the lower rubber cartridge seat, the upper end of the spray gun body is connected to the oil pipe, the lower end of the spray gun body is respectively connected to the upper end of the central pipe and the upper rubber cartridge seat, the lower rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com