Rotary kiln for calcining titanium dioxide by sulfuric acid method

A titanium dioxide, rotary kiln technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of decolorization rate, covering power fluctuation, low output of single equipment, unstable product quality, etc., to improve the transfer efficiency , Avoid prolonged contact and material sintering, and ensure the effect of high temperature residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

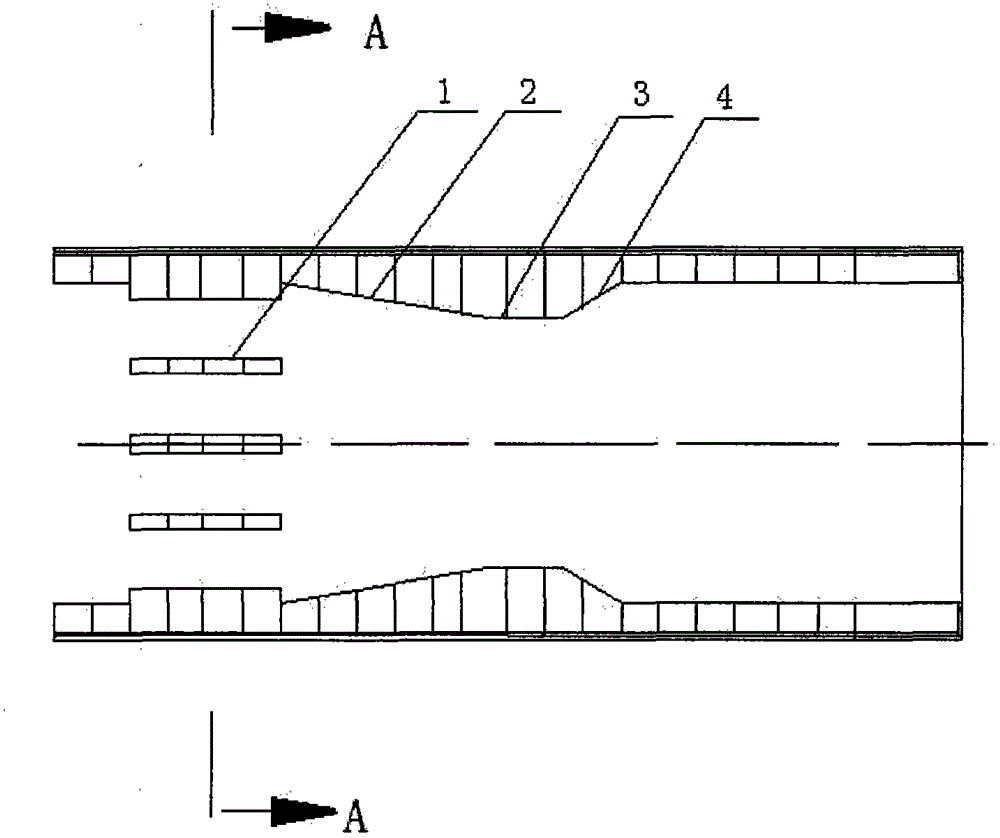

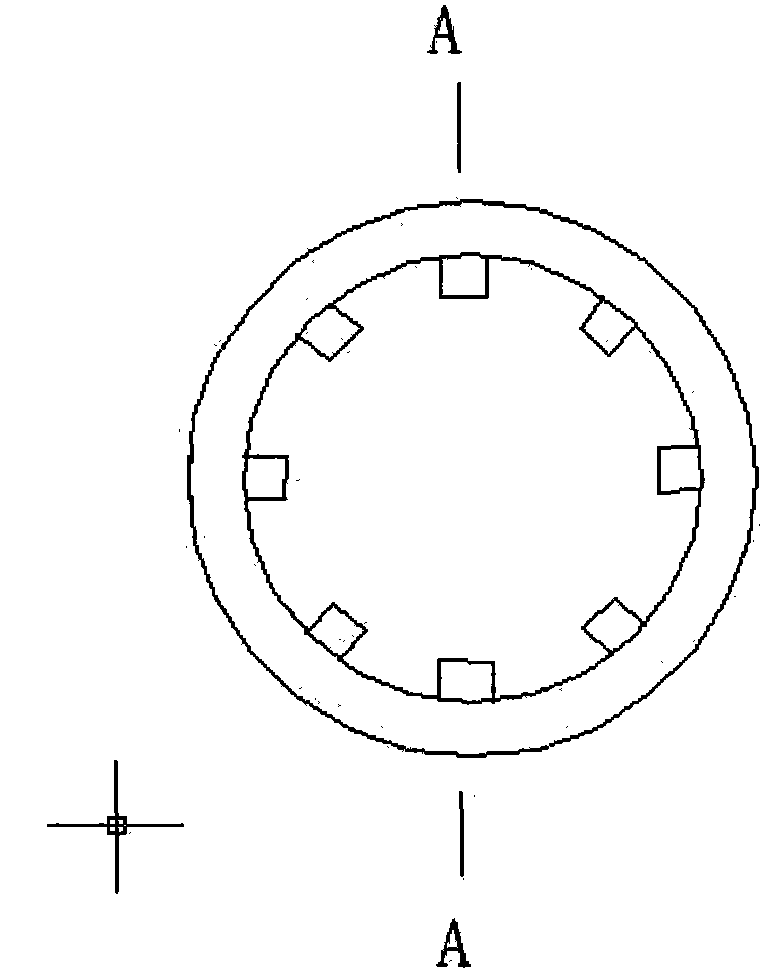

[0016] Such as figure 1 As shown, the rotary kiln used for calcining titanium dioxide has an inner diameter of 2.5m, a length of 50m, and a slope of 6%. An inverted bell mouth is set at a distance of 3.5m from the outlet of the high temperature section, and the inverted bell mouth is made of anti-stripping and anti-corrosion material. Special refractory materials, wherein the inclination angle between the constriction port (2) and the axis of the cylinder is 12°, the horizontal length is 2m, the length of the throat (3) is 400mm, and the inclination angle between the expansion port (4) and the axis of the cylinder is 20°. Such as figure 2 As shown, 8 lifting plates (1) are arranged in front of the inverted bell mouth, the length of the lifting plates is 1.5m, the height is 80mm, and the width is 80mm. During production, adjust the rotation speed to 3 minutes / circle.

[0017] The rotary kiln of the present invention increases the inclination of the cylinder, improves the ro...

Embodiment 2

[0019] Rotary kiln for calcination of titanium dioxide, the inner diameter of the cylinder is 3m, the length is 50m, the slope is set to 7%, and the inverted bell mouth is set 5.5m away from the discharge port of the high temperature section. Materials, wherein the inclination angle between the constriction port and the cylinder axis is 15°, the horizontal length is 2.5m, the throat length is 600mm, and the inclination angle between the expansion port and the cylinder axis is 25°. There are 8 lifting plates in front of the inverted bell mouth. The length of the lifting plates is 2.5m, the height is 120mm, and the width is 80mm. During production, adjust the rotation speed to 2.5 minutes / circle.

[0020] By adopting the rotary kiln in this embodiment, the white coal used per ton of titanium dioxide is reduced from 450 kilograms to 350 kilograms per ton, and energy consumption is reduced by more than 20%; the daily output of single equipment titanium dioxide is increased from 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com