Bobbin filament stripping machine

A technology of peeling machine and wire drum, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of insufficient rigidity, complicated loading and unloading, and difficult fixing, so that the possibility of failure is small and the process The process is crisp and clear, and the effect of stripping clean and neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

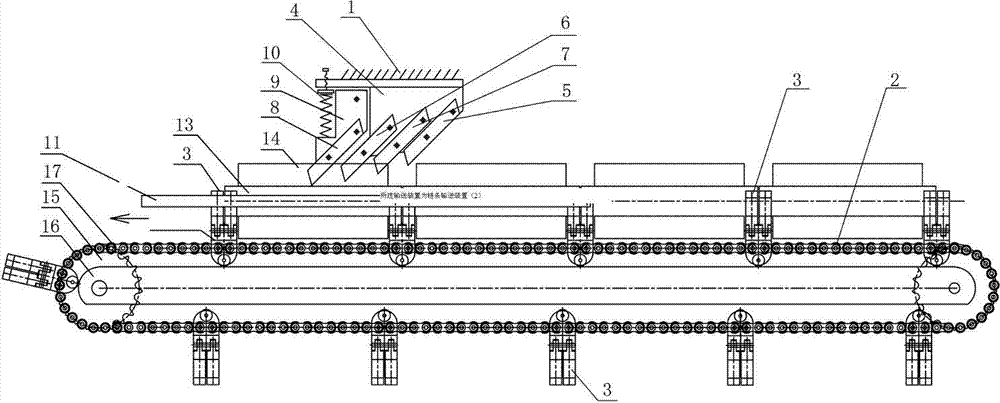

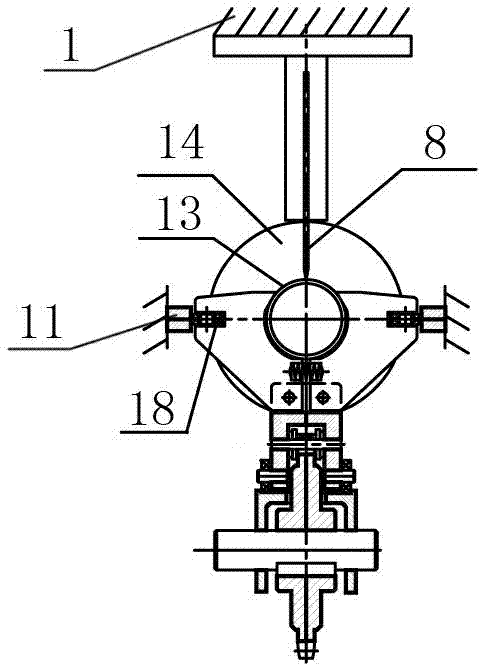

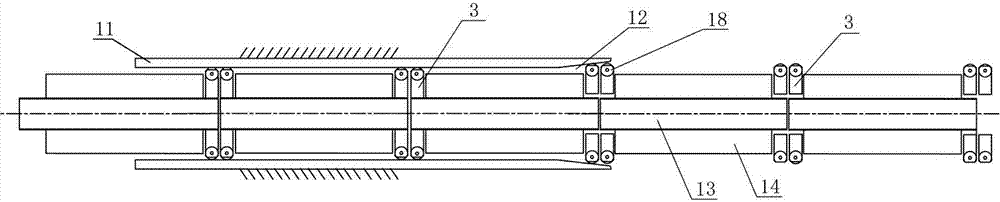

Embodiment 1

[0021] See attached Figure 1~3 , a silk bobbin stripping machine of the present invention comprises a frame 1, said frame is provided with a conveying device for unidirectionally conveying the silk bobbin, said conveying device is provided with a fixing device for fixing the silk bobbin 13, A fixed knife rest 4 is installed on the frame above the conveying device, and a fixed cutting knife is installed on the fixed knife rest 4 . Described fixed cutting knife comprises the shallow layer knife 5 that is used for shallow layer cutting and the deep layer knife 6 that is used for deep layer cutting that are arranged successively on the delivery route of directional conveying device, and the cutting edge of described deep layer knife is lower than the edge of shallow layer knife A middle knife 7 for middle cutting is also provided between the shallow knife 5 and the deep knife 6. It also includes a movable cutting knife 8, which is installed on the frame 1 through a movable knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com