Automatic paper lamination stacking machine

A stacking machine, automatic technology, applied in the direction of stacking receiving device, thin material handling, transportation and packaging, etc., can solve the problems of labor-intensive, time-consuming and labor-intensive manual collection, poor stacking quality, unqualified packaging boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

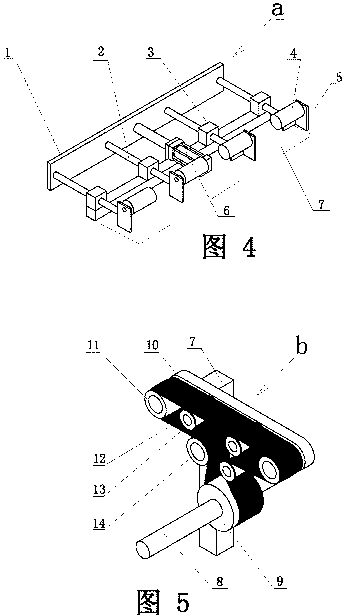

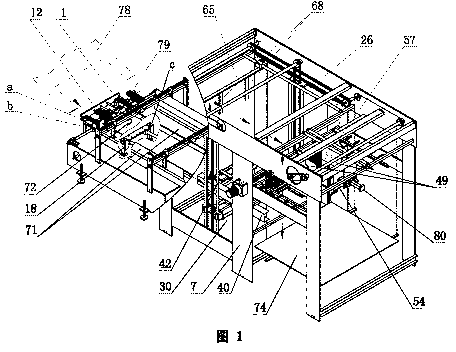

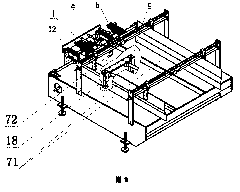

[0020] exist figure 1 and figure 2 In the shown automatic lamination stacking machine, in the lower part of the side frame 7 connected with the lamination machine 78 outlets, such as image 3 The subcomponents shown include the paper separating mechanism a, the paper feeding mechanism b and the paper pushing mechanism c. The lifting device 26 is arranged in sequence behind the sub-assembly, and the flip frame 30 that can be turned back and forth relative to the lifting device 26 is arranged on the paper moving device 65 on the top frame 7 of the lifting device 26, which is arranged on the paper moving device 65. The paper lifting mechanism 73 on the front frame is arranged on the paper lifting mechanism 73. The main frame includes a vertical alignment device 43 and a horizontal alignment device 50. The paper alignment mechanism is arranged on the paper lifting mechanism 73 and the lifting device. 26 code paper transition platforms. Among them, the paper separating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com