Angle steel punching positioning device, angle steel punching equipment and angle steel positioning punching method

A technology of positioning device and hole position, which is applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of many preparations, lower punching efficiency, cumbersome positioning of angle steel punching, etc., to achieve a simple positioning method and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

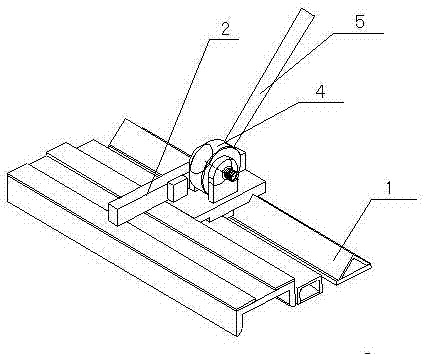

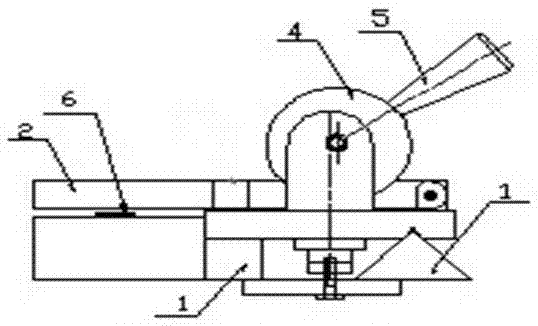

[0024] The angle steel punching device of the present invention comprises a guide rail 1, a baffle plate 2 and a clamping device, the baffle plate 2 and the clamping device are arranged on the guide rail 1 and can slide along the guide rail 1, and the clamping device is used to fix the position of the baffle plate 2, The baffle plate 2 and the clamping device are arranged coaxially, and the baffle plate 2 can rotate along the axis to a position extending laterally above the angle steel seat. The clamping device includes an eccentric wheel 4 and a handle 5, the handle 5 is fixed on the eccentric wheel 4, and the action of the handle 5 drives the eccentric wheel 4 to move.

Embodiment 2

[0026] The technical scheme of the angle steel punching equipment of the present invention is such: it comprises angle steel base, punching device, and angle steel is dragged along angle steel base to carry out punching, and steel plate ruler 6 is set on the angle steel base, and it also comprises angle steel punching positioning device, The number of angle steel punching and positioning devices corresponds to the number of punching holes. The angle steel punching and positioning device is arranged on the inner side of the angle steel seat, which includes guide rail 1, baffle plate 2 and clamping device. The baffle plate 2 and clamping device are arranged on the The guide rail 1 can slide along the guide rail 1. The clamping device is used to fix the position of the baffle 2. The baffle 2 and the clamping device are coaxially arranged. The baffle 2 can be rotated along the axis to extend laterally above the angle steel seat. . The clamping device includes an eccentric wheel 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com