Powder quantitative weighing and die throwing integrated production equipment and work method thereof

A production equipment, quantitative weighing technology, applied in the direction of automatic feeding/discharging weighing equipment, weighing, measuring devices, etc. Avoid the phenomenon of lifting over-position, improve production efficiency, and the effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

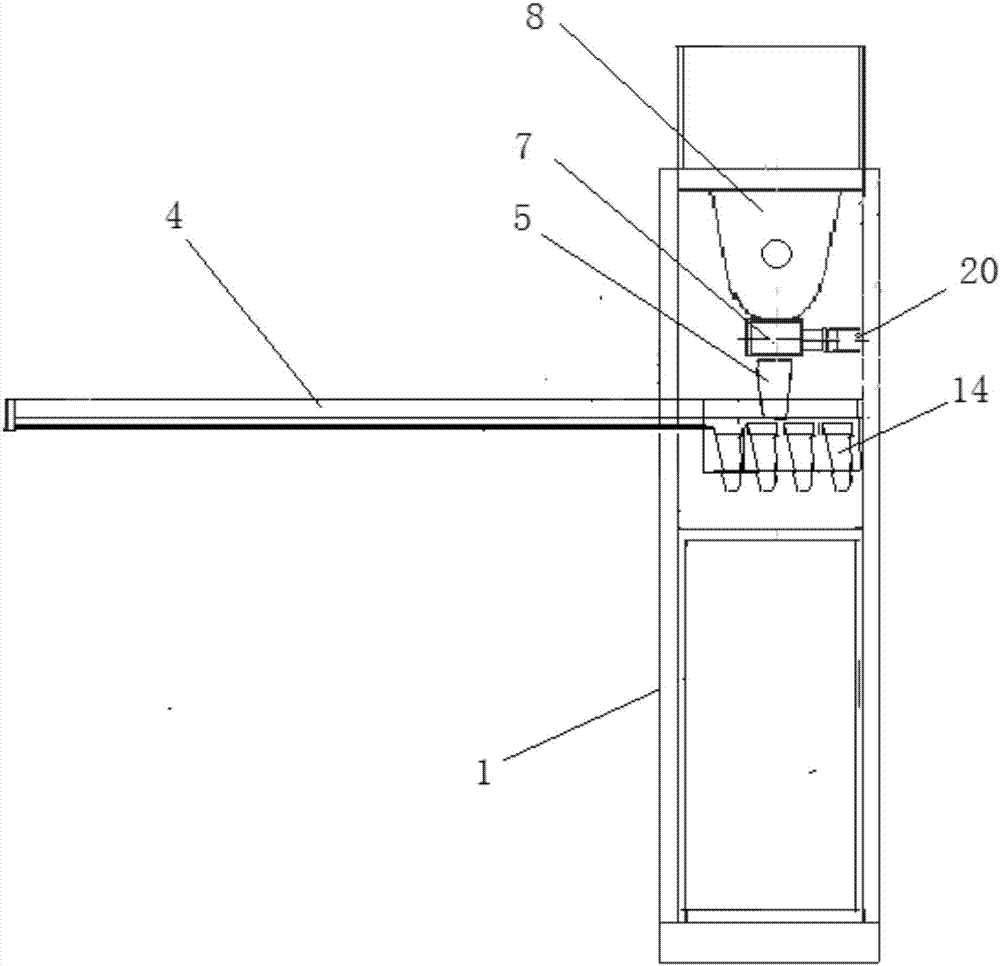

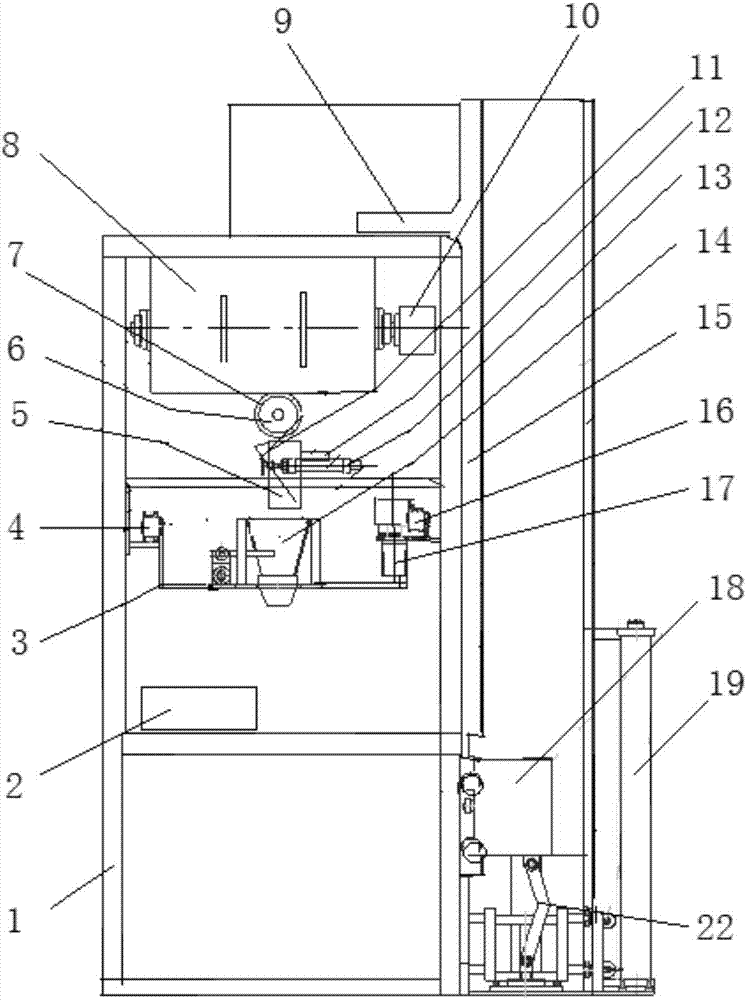

[0043] like figure 1 figure 2 As shown in the figure, an integrated production equipment for powder quantitative weighing and casting is composed of a feeding mechanism, a storage bin 8, a feeding mechanism, a sub-packaging weighing mechanism, a material transporting mechanism, an unloading mechanism arranged on the equipment rack 1 The material mechanism and the controller 2 are composed;

[0044] The storage bin 8 is arranged on the top of the equipment rack 1, and a discharging port is arranged in the middle of the bottom of the storage bin 8, and a set of feeding mechanism and a sub-packaging weighing mechanism are corresponding to the bottom of the discharging port;

[0045] The structure of the feeding mechanism is as follows figure 2 As shown, a vertical guide rail 15 leading to the storage bin 8 is provided behind the equipment rack 1 from the bottom to the top, and a section of flat rail 9 protrudes from the discharge height of the vertical guide rail 15 to the to...

Embodiment 2

[0053] Example 2 is as figure 1 and Figure 4 As shown, it is basically the same as the technical solution of Embodiment 1. It consists of a feeding mechanism, a storage bin 8, a feeding mechanism, a sub-packing weighing mechanism, a material transporting mechanism, a discharging mechanism and a controller 2 arranged on the equipment rack. composition; the difference is:

[0054] The bottom of the storage bin 8 is provided with two feeding openings, and the two feeding openings are arranged in the front and rear in the length direction of the storage bin, and each feeding opening corresponds to a set of feeding mechanism and sub-packaging weighing. mechanism;

[0055] A servo motor 17 and two rows of feeding boxes 14 with discharge doors 21 are installed on the small frame 3 of the material transporting mechanism, and each row of feeding boxes corresponds to its own weighing mechanism; The transverse links 23 are connected together by the longitudinal links 25 and are joint...

Embodiment 3

[0058] Example 3 is a powder quantitative weighing and mold casting integrated production equipment designed on the basis of Example 1. Multiple materials are sequentially injected into the mold. Example 3 is an example of two powder materials.

[0059] like image 3 and figure 2 As shown, the technical solution of Embodiment 3 is basically the same as that of Embodiment 1. Controller 2 consists of; the difference is:

[0060] The feeding mechanism, the storage bin 8, the feeding mechanism and the sub-packaging and weighing mechanism are arranged in two sets according to the variety and number of powder materials, one for each powder material, and they are placed in the feeding direction of the equipment rack 1 according to the feeding direction. The modules are arranged sequentially; where:

[0061] The two sets of feeding mechanisms share a stepping motor 20, the stepping motor 20 is arranged between the two runners 6, and the two axial ends of the stepping motor 20 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com