System and method for testing camera module stains

A camera module and testing system technology, which is applied in the direction of optical testing flaws/defects, TVs, electrical components, etc., and can solve problems such as different visual senses, tiny particles falling into it, and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

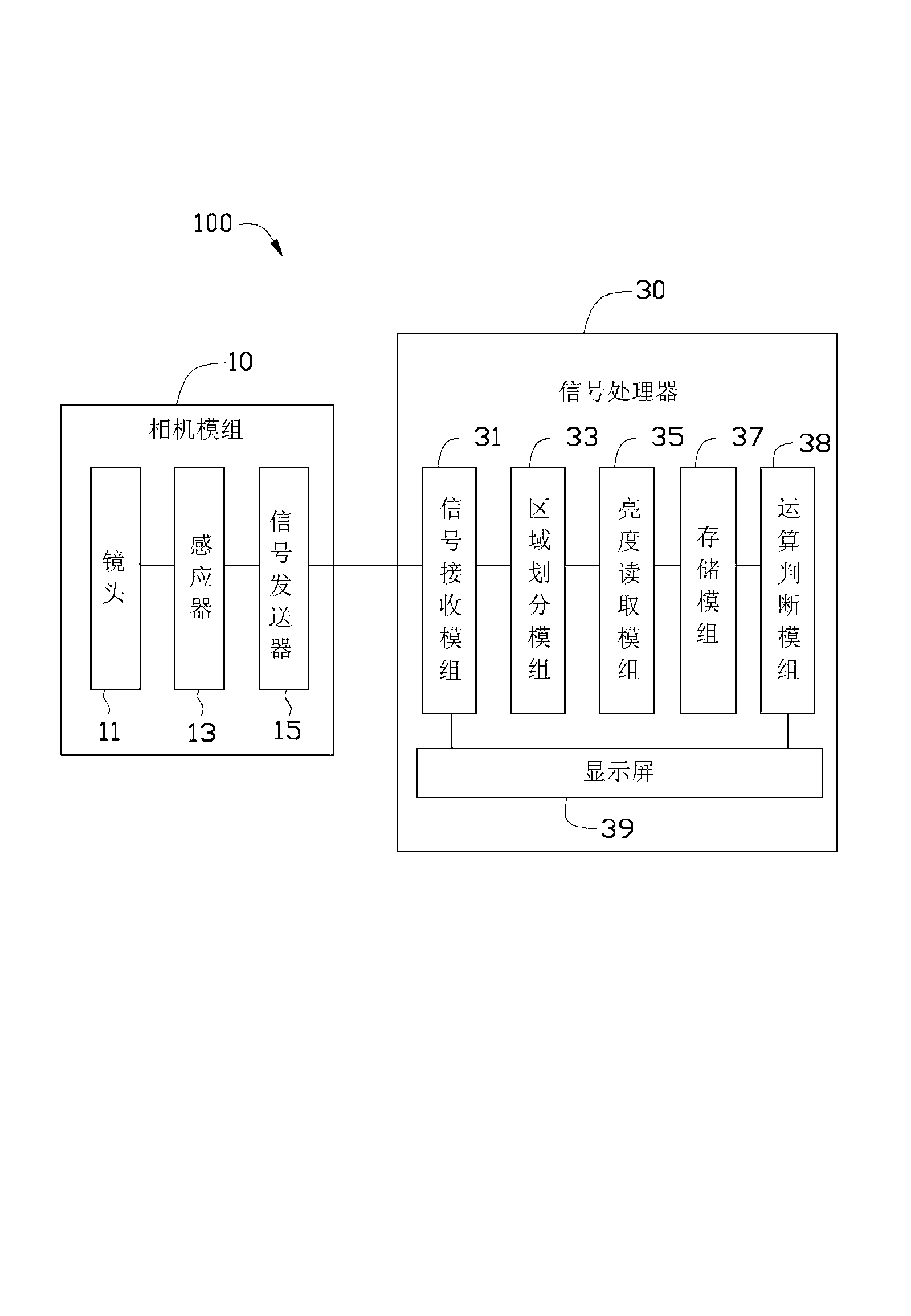

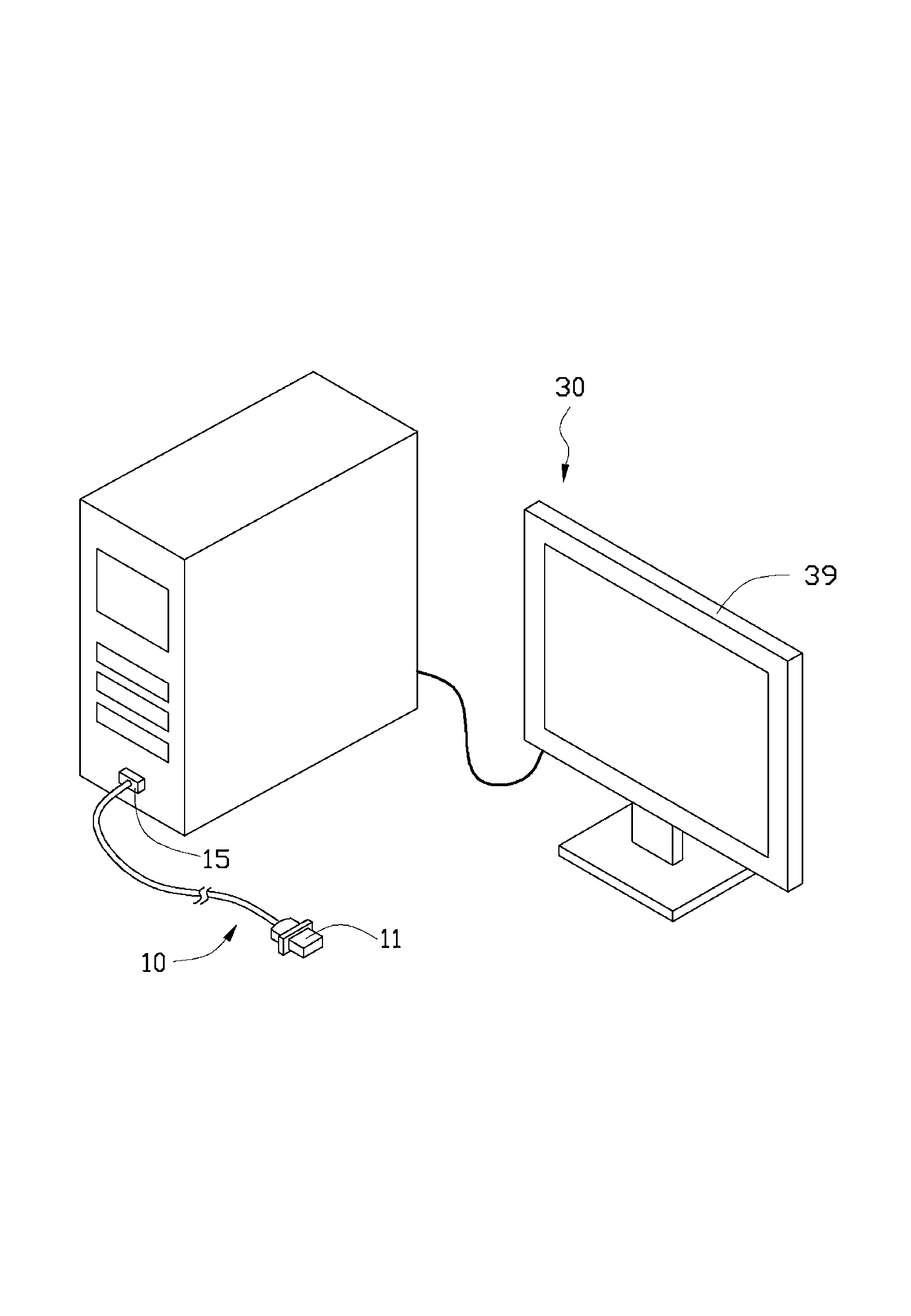

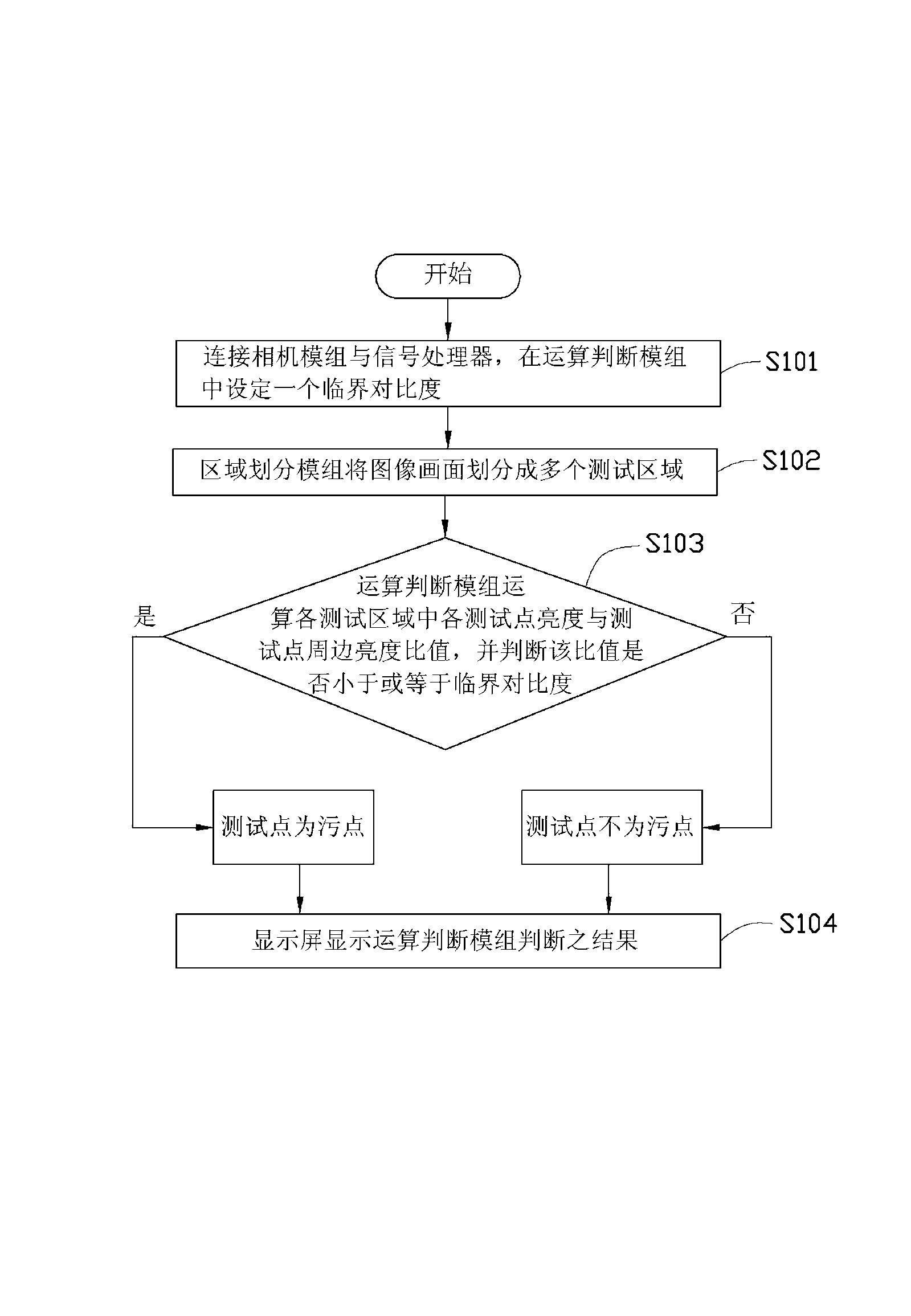

[0019] see figure 1 and figure 2 , the camera module stain testing system 100 of this embodiment includes a camera module 10 and a signal processor 30 . The camera module 10 includes a lens 11 , a sensor 13 and a signal transmitter 15 . The signal transmitter 15 is connected to a signal processor 30 . The sensor 13 collects images through the lens 11 , and then sends the image signal collected by the sensor 13 to the signal processor 30 through the signal transmitter 15 .

[0020] The signal processor 30 includes a signal receiving module 31 , an area division module 33 , a brightness reading module 35 , a storage module 37 and an operation judgment module 38 . In this embodiment, the signal processor 30 is a calculator, and the signal processor 30 also includes a display screen 39 . It can be understood that the signal processor 30 may adopt a single chip microcomputer or other programmable intelligent devices. Of course, the signal processor 30 is not limited to this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com