Thermistor manufactured by ceramic thin films and manufacturing method of thermistor

A technology of ceramic thin film and thermistor, applied in the direction of resistors with negative temperature coefficient, etc., can solve the problems of insufficient production efficiency, inconsistent shape and size, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method for manufacturing a thermistor by using a ceramic thin film will be described in detail below with reference to the accompanying drawings.

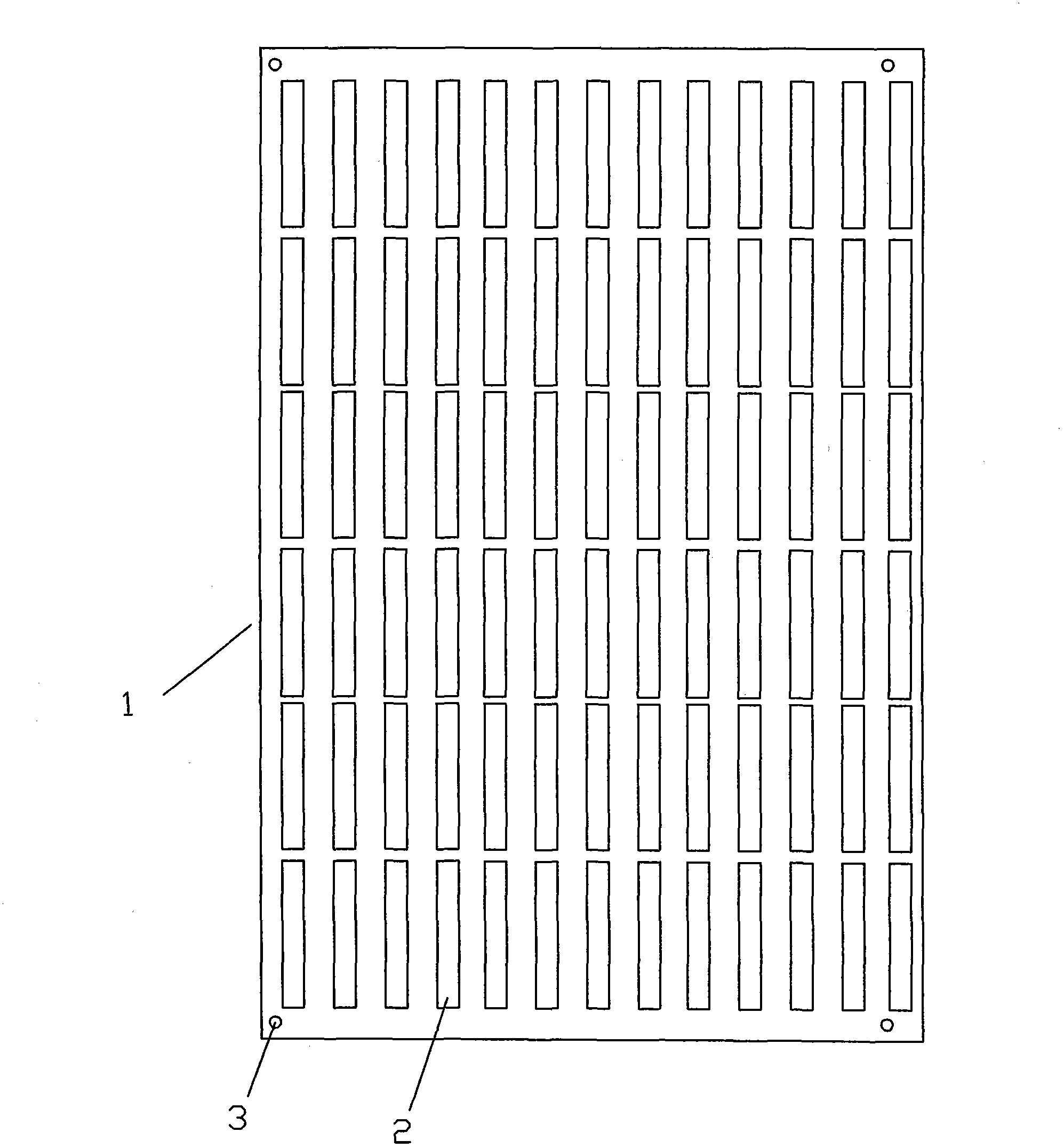

[0023] 1. If figure 1 Shown: Select the required ceramic film, cut it into a rectangular ceramic film (1), punch out uniformly distributed strip windows (2) on the rectangular film, and punch out film positioning holes (3) at the four corners of the rectangular film .

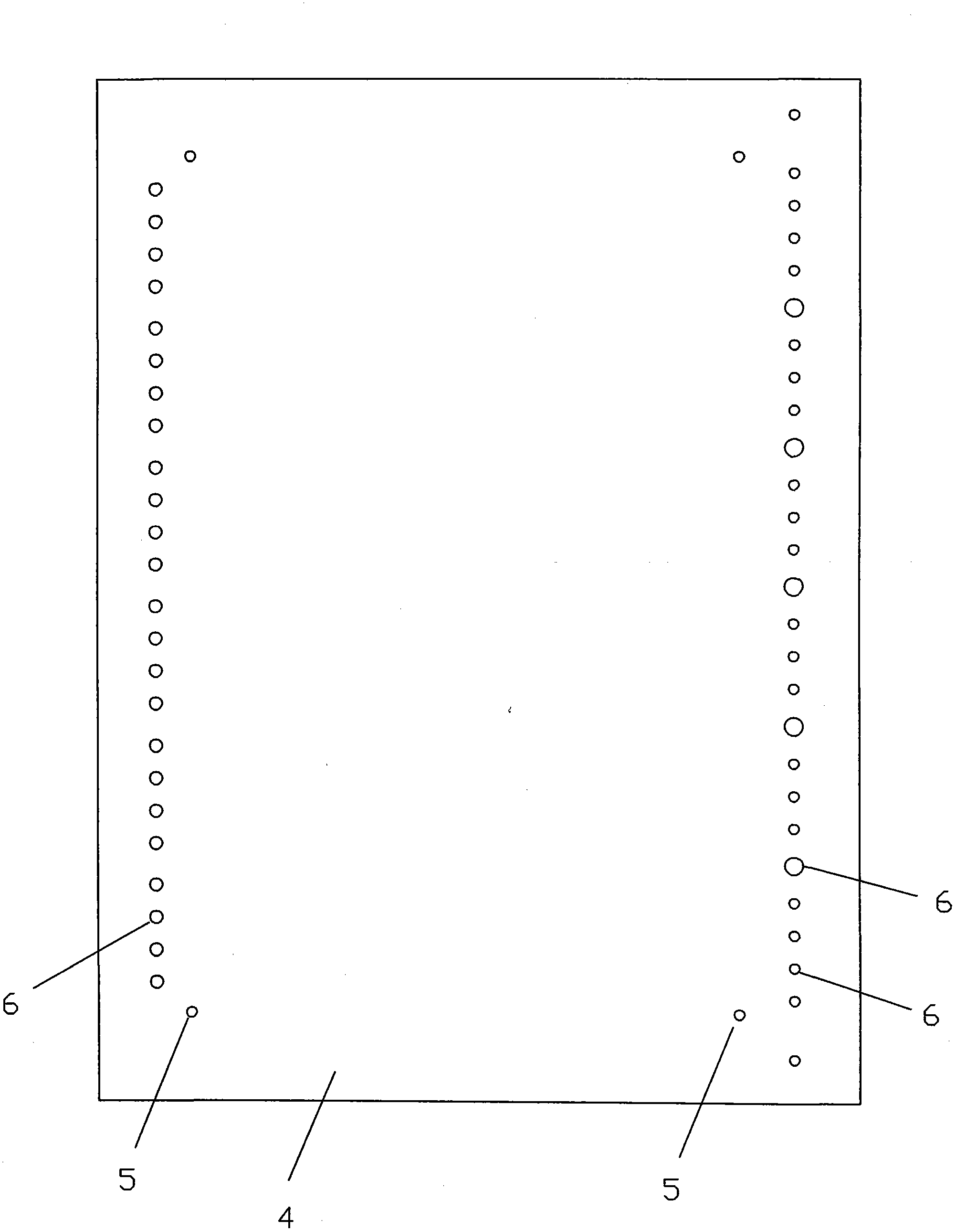

[0024] 2. If figure 2 As shown: on a rigid floor (4) whose length and width are 2 to 3 cm larger than the rectangular film, four positioning piles (5) are arranged corresponding to the positioning holes on the rectangular film; Distributed winding stakes (6).

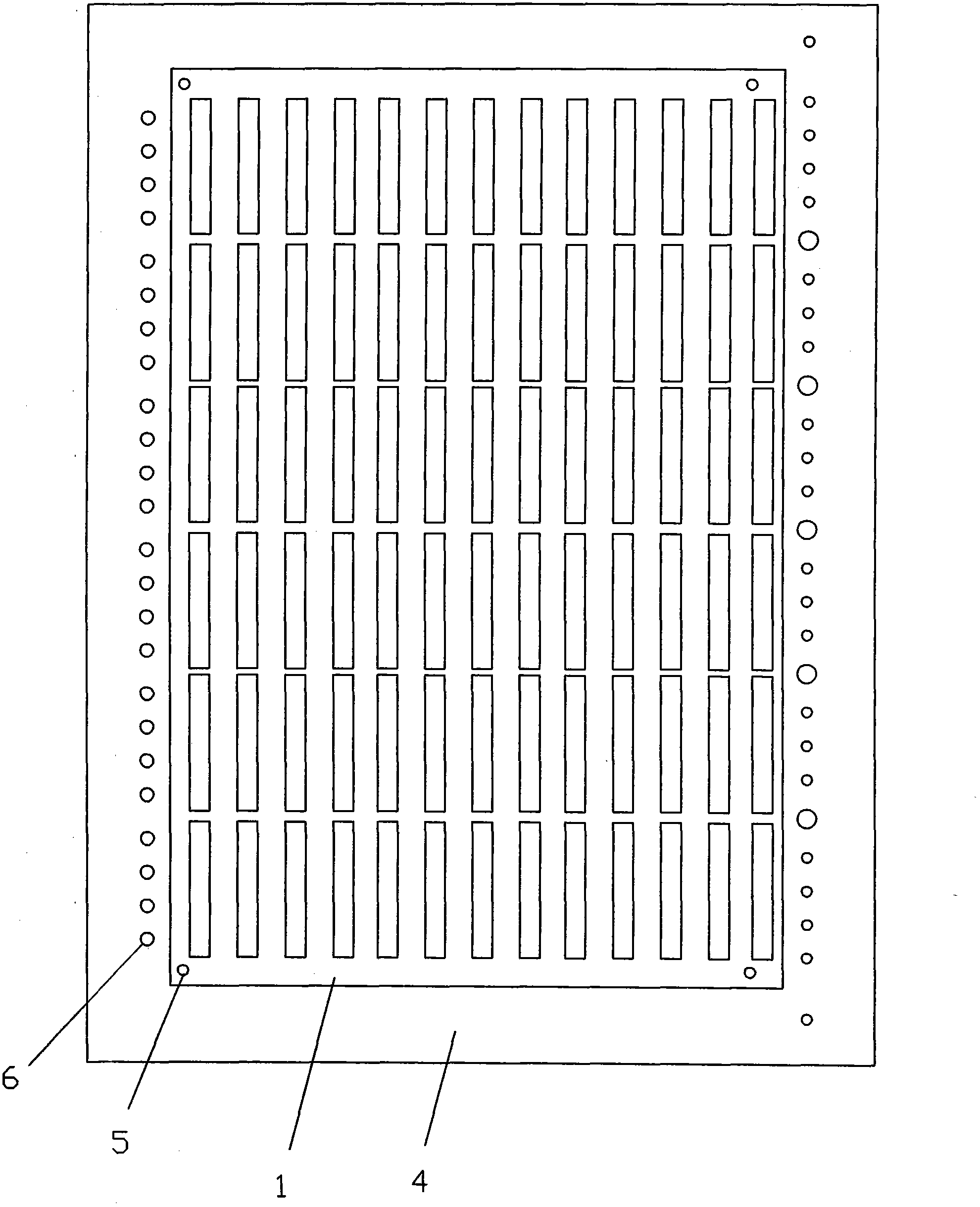

[0025] 3. If image 3 Shown: a layer of rectangular ceramic film (1) is placed on the rigid base plate (4), and the positioning holes of the film are sleeved on the four positioning piles (5) of the rigid base plate.

[0026] 4. If Figure 4 Shown: the metal wire (7) is passed around the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com