Air cooled heating pump test system

A test system, air-cooled heat pump technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve problems such as high energy consumption, and achieve the effect of saving the energy consumption of unit testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

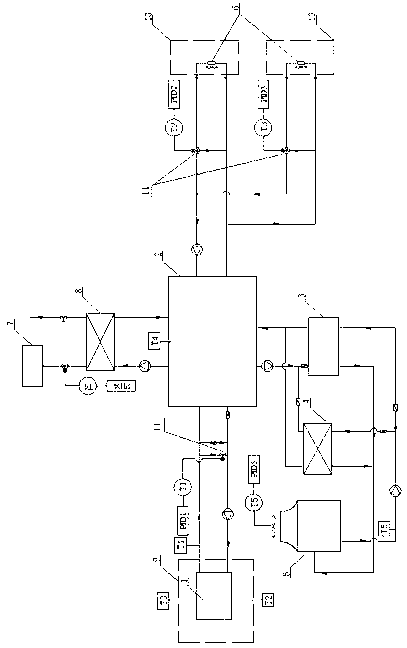

[0009] Such as figure 1 The structure diagram of the air-cooled heat pump test system is shown, the tested unit environmental chamber 9 is used to place the tested unit 1, the tested unit environmental chamber 9 is equipped with an air intake and exhaust control system, and the air treatment box 10 is installed in the tested unit environmental chamber Inside 9, part of the cold water produced during the operation of the tested unit 1 enters the heat balance water tank 2, and the other part is mixed with the water from the heat balance water tank 2 and then enters the evaporator of the tested unit 1. By adjusting the mixing ratio of the two parts of water , to realize the outlet water temperature control of the tested unit 1, the condensation heat generated by the condenser of the tested unit 1 is taken away by the surface cooler 6 in the air handling box 10 placed in the tested unit’s environmental chamber 9 after heat exchange, and the surface cooling The refrigerant water fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com