Gasifier monitoring device

A technology for monitoring devices and gasifiers, which is applied to the safety devices of combustion chambers, combustion ignition, and combustion methods. The effect of complexity, increased security stability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Along with the use of new type integrated start-up burner, original ignition burner stops using, and this has just emptied an effective channel for gasification furnace, and the present invention just appears on this basis.

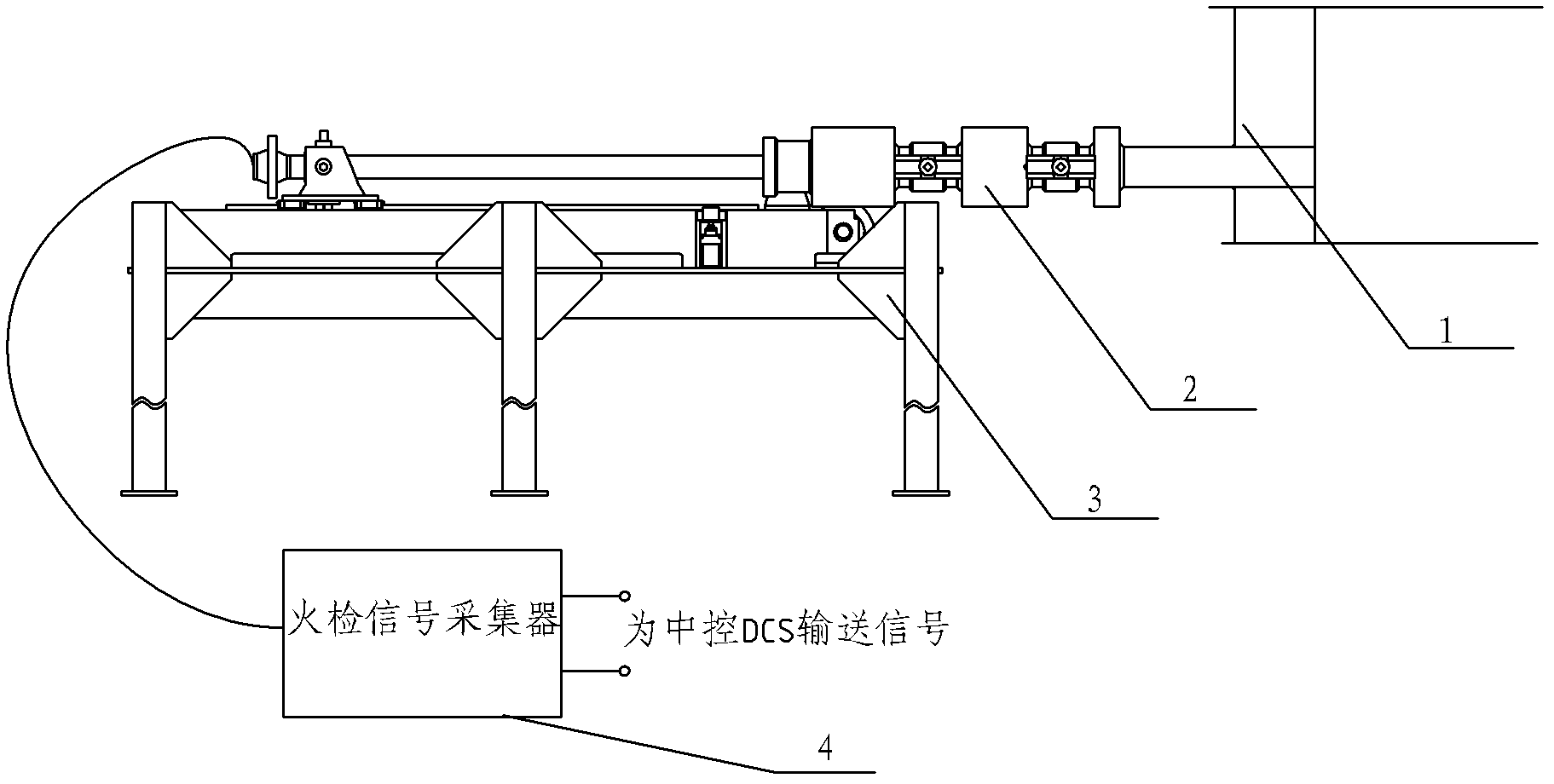

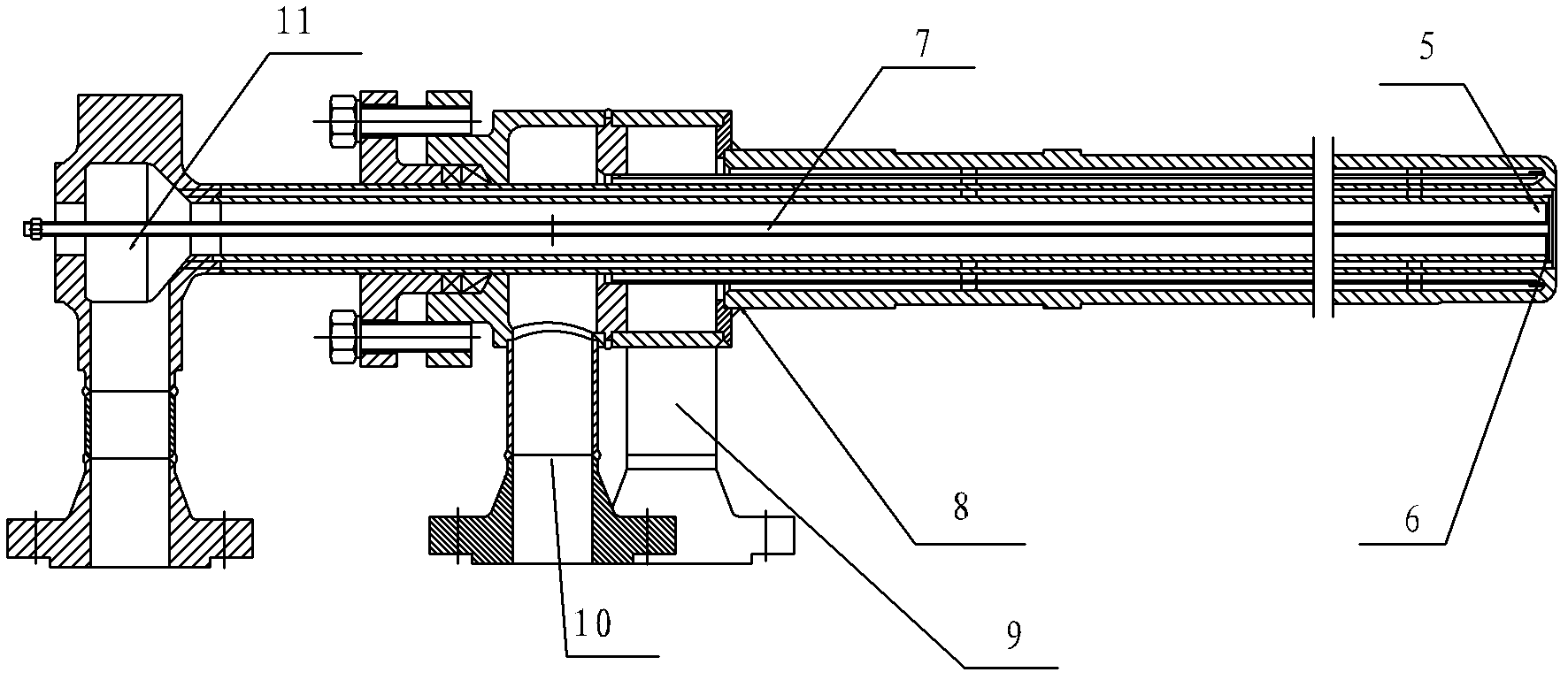

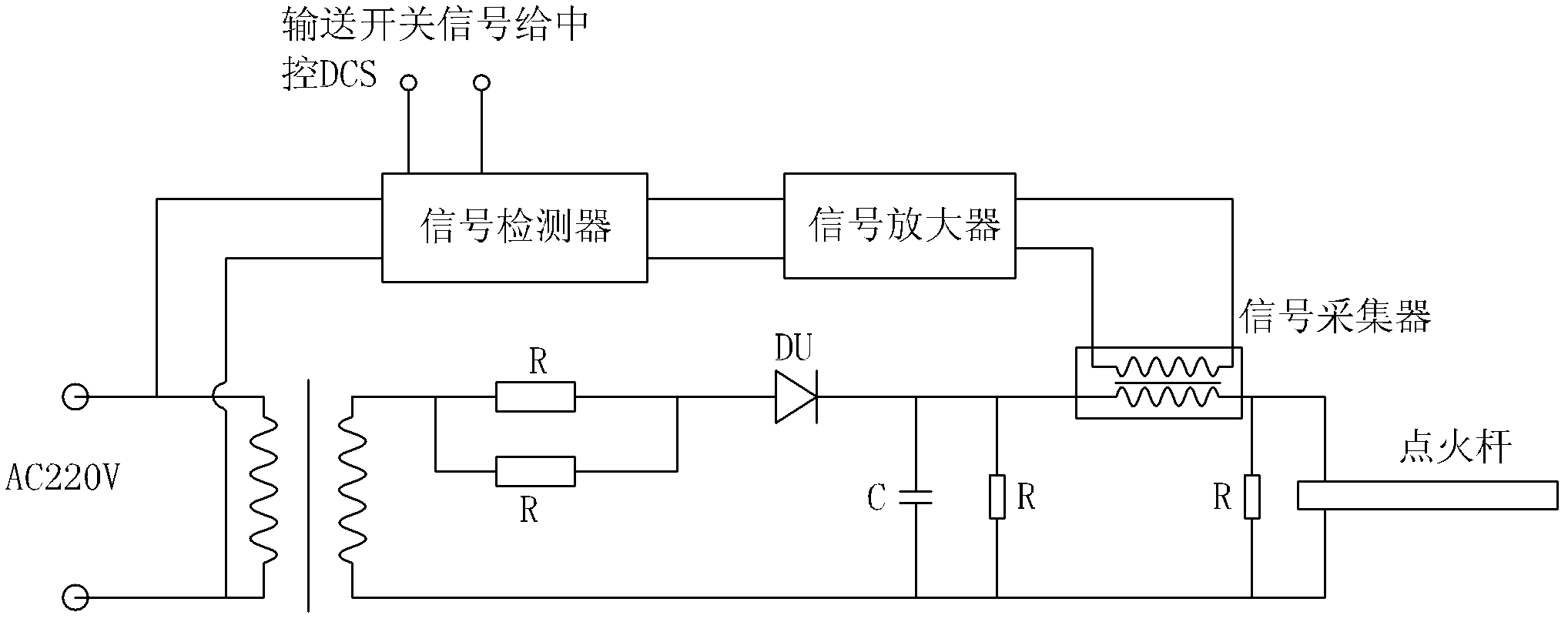

[0016] Such as figure 1 As shown, the present invention includes a furnace monitoring mechanism 2 and an electronic ignition detection device. The monitoring mechanism is similar in shape to the ignition burner and extends into the furnace 1 . The present invention adopts a multi-tube structure, the outermost jacket is the cooling water inlet channel 9, and the inner jacket is the cooling water outlet channel 10; cooling water flows continuously during operation, so that the outer surface of the shell 8 is always kept in a safe Within the temperature range, the adaptability of the monitoring mechanism in the high temperature and high pressure environment is effectively improved; the head of the shell is designed with double-layer transparent glass,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com