Fan blade

A fan blade and fan technology, which is applied to wind turbines, wind turbine components, engines, etc., can solve problems such as damage to fan blades, buckling failure of fan blades, and large loads, so as to improve buckling resistance, avoid glue opening, and improve Effects on Structural Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

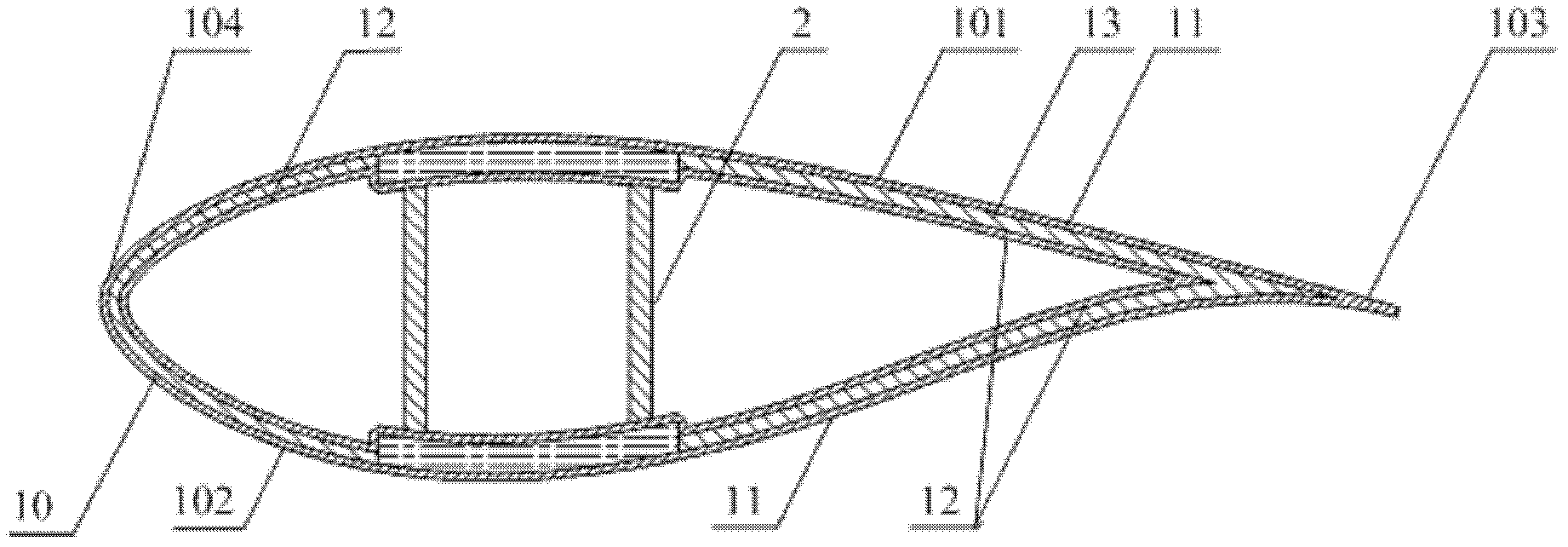

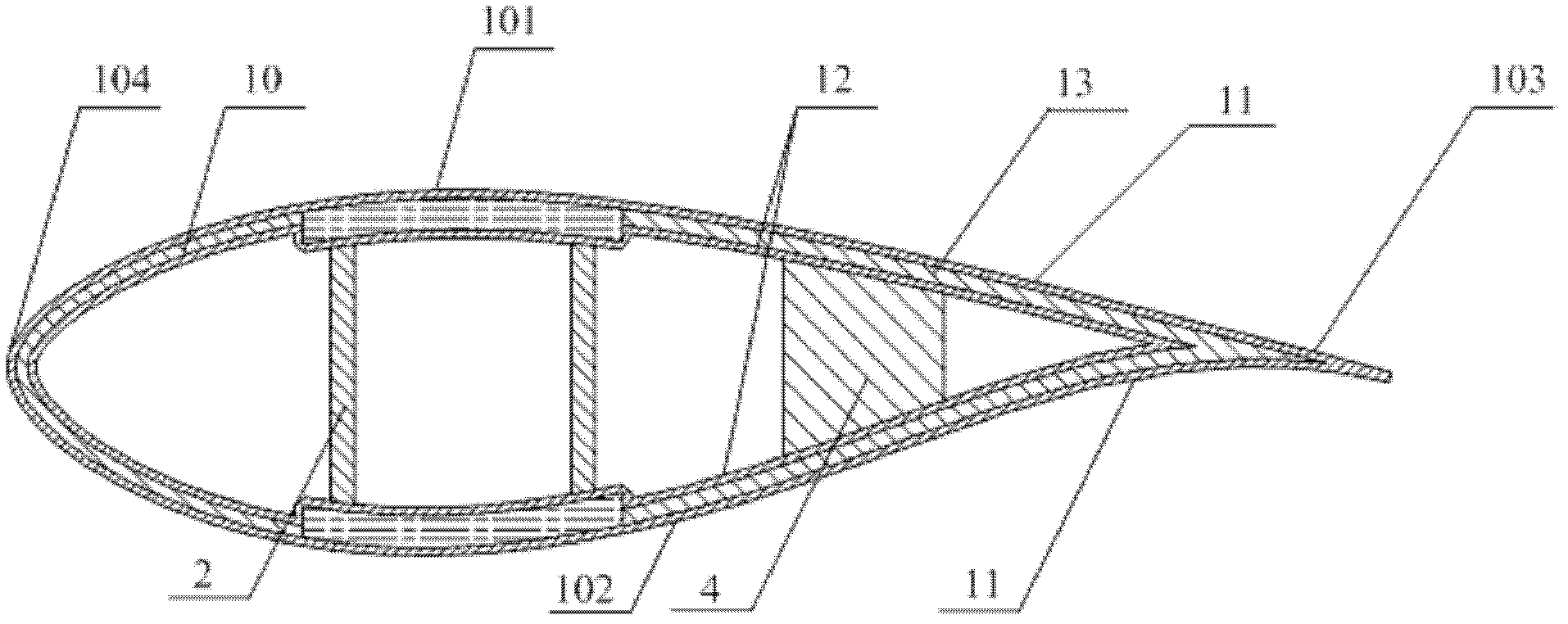

[0014] figure 2 It is a schematic cross-sectional structure diagram of an embodiment of the fan blade of the present invention. Please refer to figure 2 , the present embodiment provides a fan blade, including: a closed fan casing 10 formed by butting the upper casing 101 and the lower casing 102, and a shear web 2 is arranged in the cavity formed inside the fan casing 10 , the top and bottom ends of the shear web 2 are fixedly connected to the beam caps on the upper shell 101 and the lower shell 102 respectively, and a The connecting body 4 is fixedly connected to the upper shell 101 and the lower shell 102 respectively.

[0015] Specifically, the upper shell 101 and the lower shell 102 are docked to form a closed fan casing 10, and the tip formed by the docking of the upper shell 101 and the lower shell 102 is the rear edge 103 of the fan blade, and the rear edge 103 is relatively smooth. One end is the front edge 104; the beam caps can be respectively fixedly embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com