Double-power engine with adjustable hydraulic and mechanical power output ratio

A mechanical power and engine technology, applied in the field of internal combustion engines, can solve the problems that the engine cannot output hydraulic pressure and machinery at the same time, the top dead center of the engine is not fixed, and the top dead center is not fixed, etc., to achieve fast power transmission, reliable principle and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

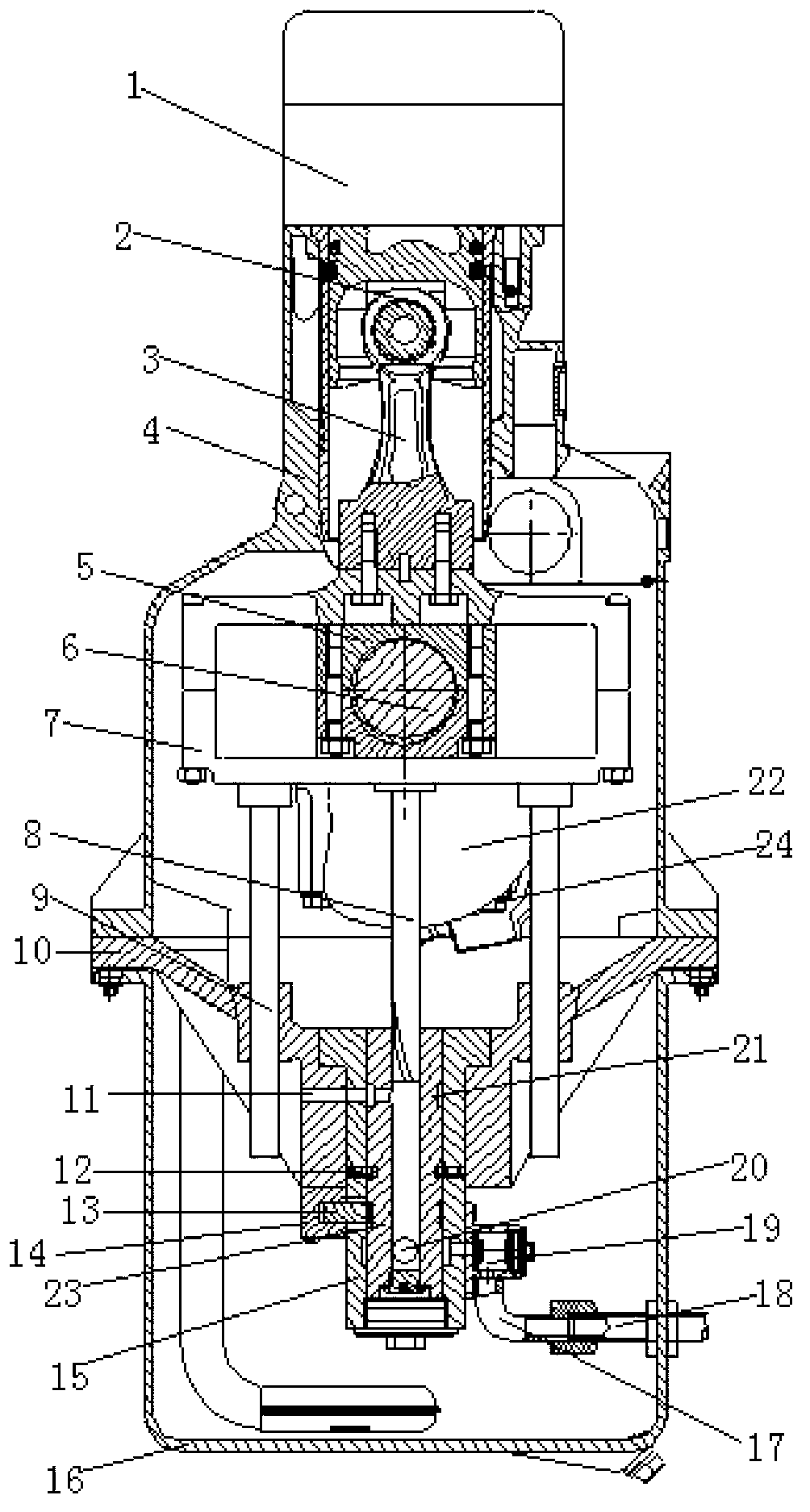

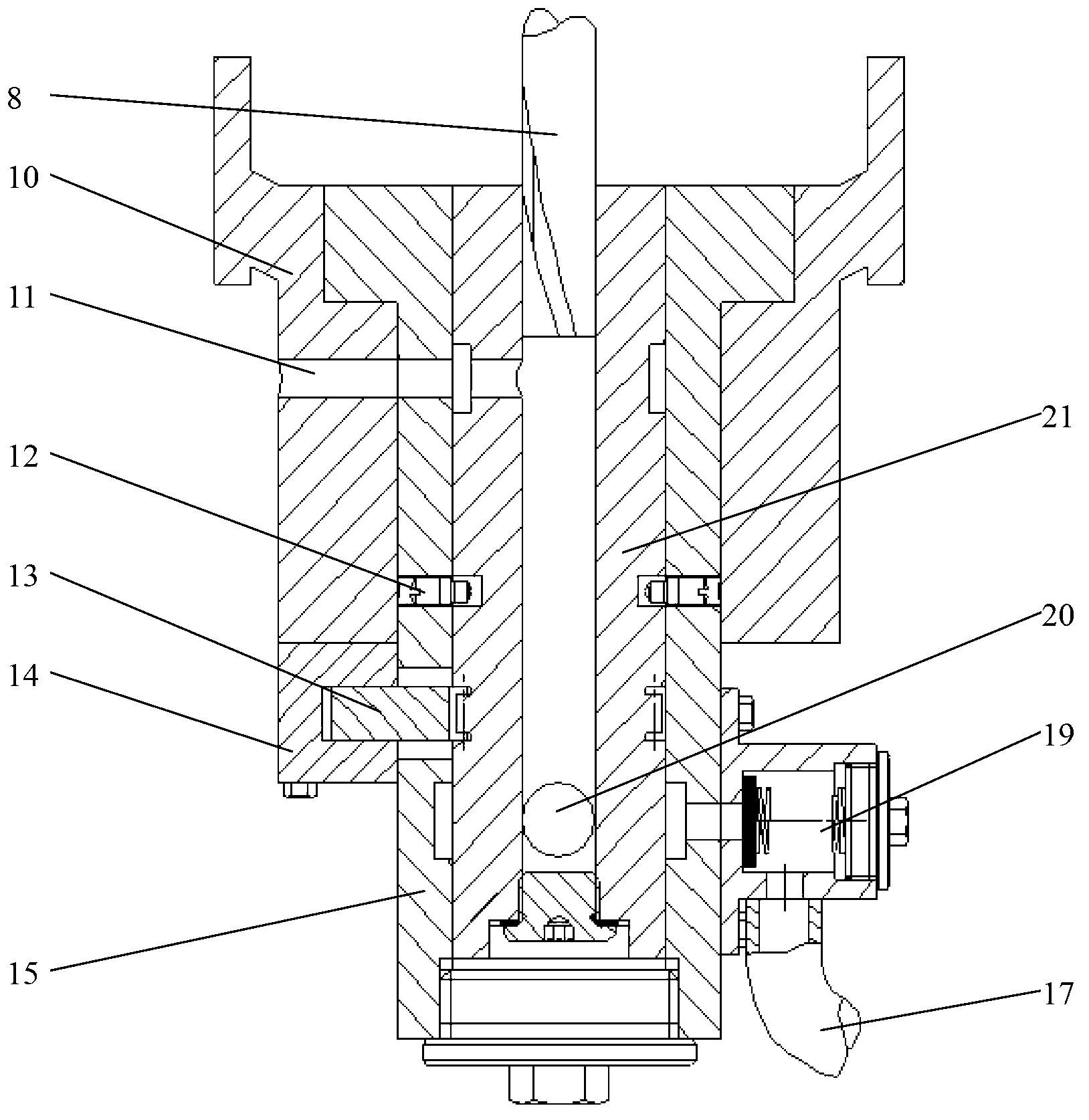

[0011] The main structure of this embodiment includes cylinder head 1, piston 2, connecting rod 3, cylinder block 4, slider 5, crank pin 6, slider groove 7, plunger 8, guide rod 9, pump bracket 10, oil inlet hole 11. Plunger sleeve limit screw 12, plunger stroke adjustment rack 13, rack bracket 14, plunger pump casing 15, oil pan 16, oil outlet pipe 17, oil outlet pipe 18, oil outlet valve 19, plunger Oil outlet hole 20, plunger sleeve 21, crankshaft 22, plunger pump 23 and bearing housing 24; its combustion process is the same as that of a traditional reciprocating piston four-stroke engine, and is composed of cylinder head 1, piston 2 and cylinder block 4. In the combustion chamber, the expansion force generated by combustion is sent out in two ways through the connecting rod 3, one of which passes through the slider 5, the slider groove 7, the plunger 8, including the plunger pump casing 15, the plunger sleeve 21, and the oil outlet valve 19 The plunger pump with oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com