Drilling tool and method for detecting reservoir stratum boundary and thickness while drilling

A drilling tool and boundary surface technology, which is applied in the field of geological exploration, can solve the problems such as the difficulty of the drilling tool to move forward, the inability to completely maintain the wellbore trajectory, and the inability to quantitatively measure it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

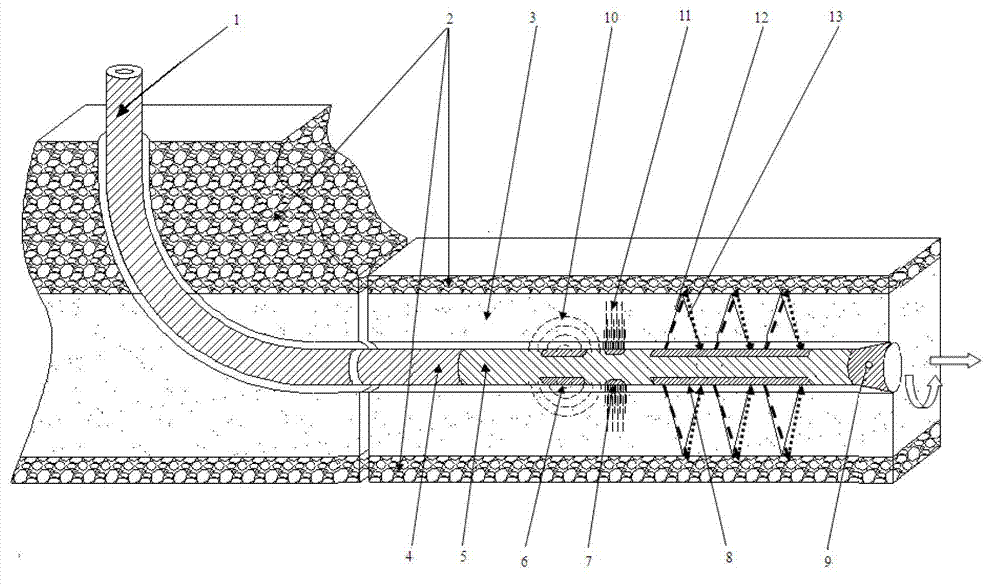

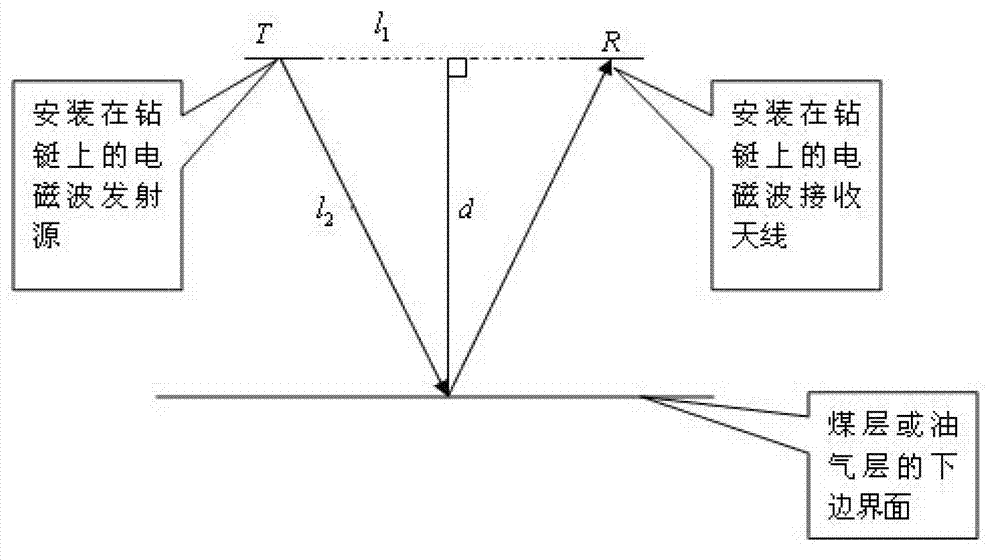

[0024] A drilling tool mainly includes drill rods, screw motors and drill collars connected in sequence, and also includes dielectric constant measuring probes installed on the upper and lower sides of the drill collar, and natural gamma ray probes installed on the upper and lower sides of the drill collar. A sensor, an electromagnetic wave transmitting source and a receiving antenna installed on the upper and lower sides of the drill collar.

[0025] Wherein, the dielectric constant measuring probes installed on the upper and lower sides of the drill collar are natural gamma ray sensors installed on the upper and lower sides of the drill collar for judging and identifying the lithology of the formation where the drilling tool is located.

[0026] Among them, the drill collar equipped with ultra-high frequency electromagnetic wave and microwave emission source, receiving antenna, gamma sensor and dielectric constant measuring probe is arranged near the drill bit before the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com