Synchronous measurement method and apparatus for dynamic and static rock mechanical parameters

A technology for simultaneous measurement of rock mechanical parameters, applied in the application of stable tension/pressure to test the strength of materials, and the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem that the validity and accuracy of rock mass mechanical parameters of oil and gas reservoirs cannot be guaranteed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

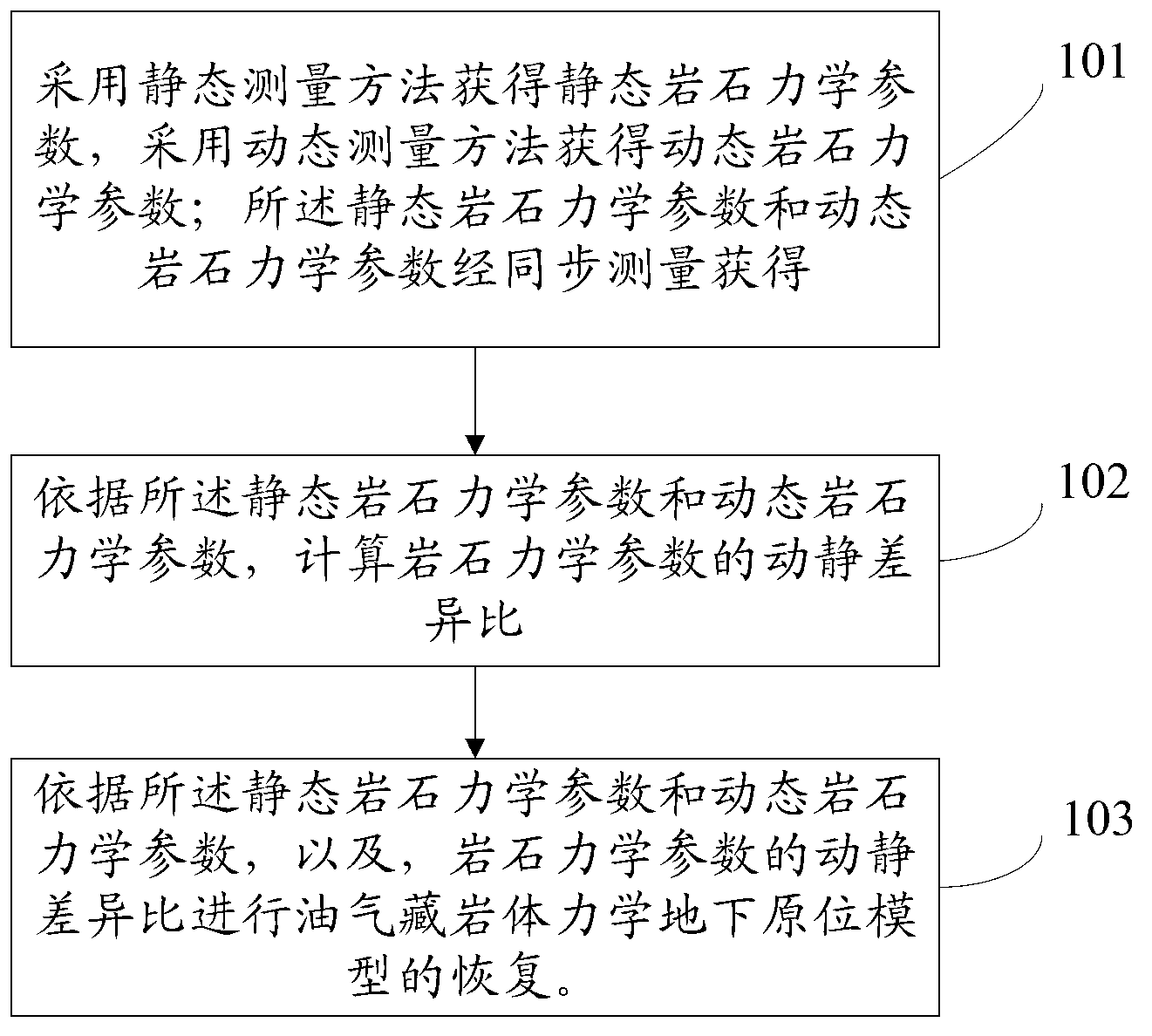

[0087] One of the core ideas of the present invention is to quantitatively describe the difference between the dynamic and static test results of rock mass mechanics parameters, and analyze the microcosmic mechanism of the difference and the factors affecting the difference value, and give the dynamic and static test results. Conversion relation; by obtaining accurate and effective dynamic and static parameters of rocks, the validity and effectiveness of rock mass mechanical parameters of oil and gas reservoirs with complex confining pressure, high temperature, high pore pressure and multiphase fluids deep underground can be guaranteed. accuracy.

[0088] refer to figure 1 , which shows a flow chart of steps of an embodiment of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com