Stone curtain wall structure

A stone curtain wall and stone technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as high risk, unsuitable for drilling or slotting machining, and impact on the safety of stone plates, and achieve the goal of installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

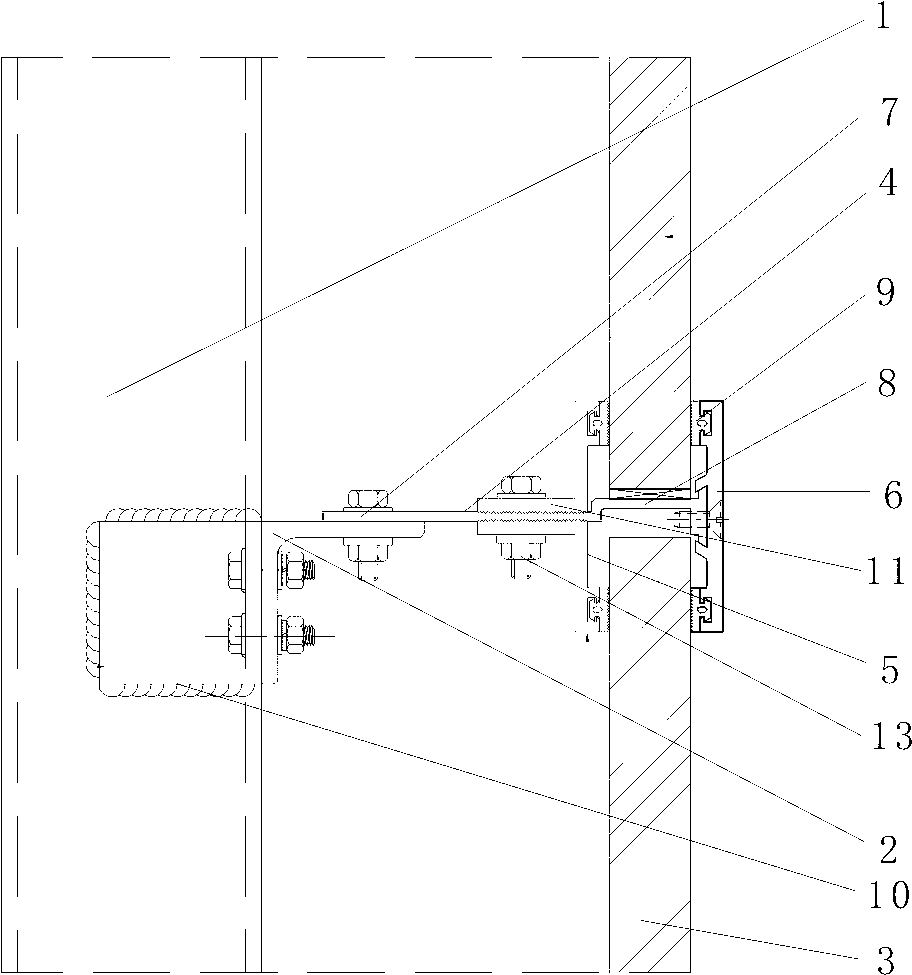

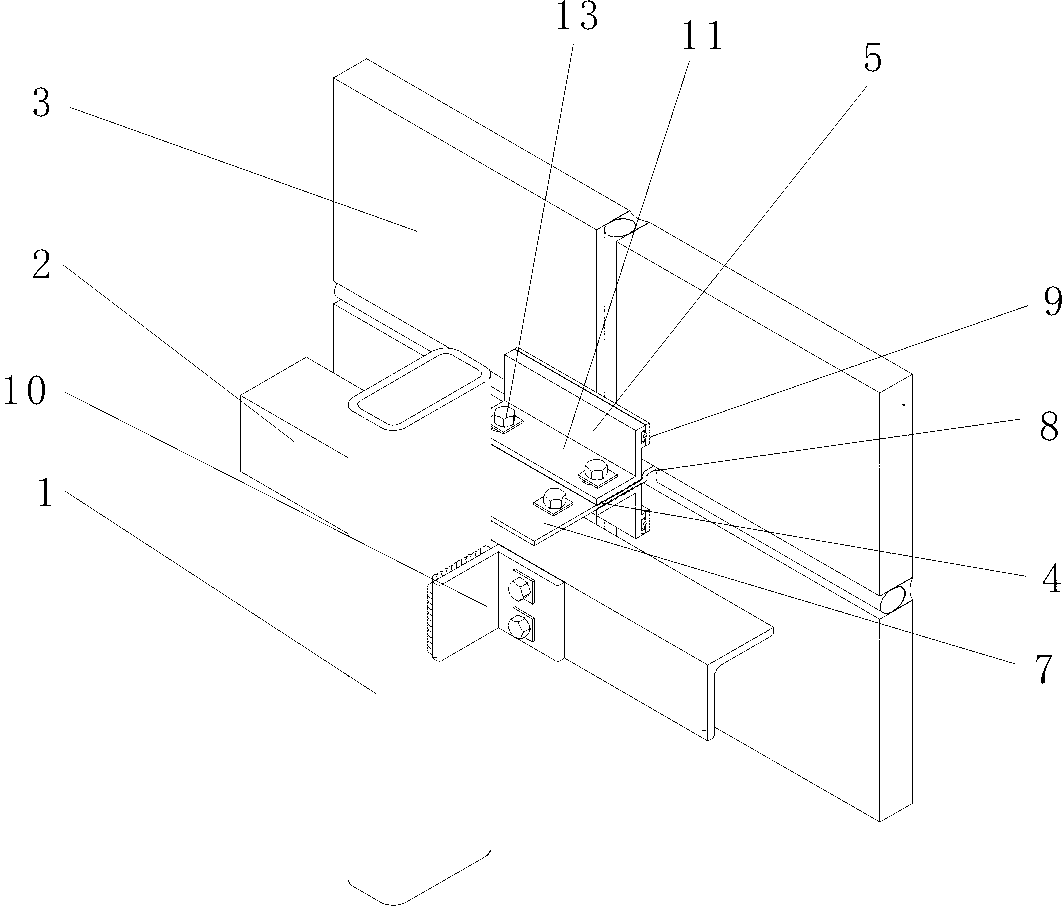

[0013] Such as figure 1 As shown, the stone curtain wall structure of the present invention includes a column 1, a beam 2, a connecting piece and a stone panel 3. The column 1 can be a square steel tube, and the beam 2 can be an angle steel. The crossbeam 2 is fixed on the column 1, and the crossbeam 2 is fixed on the column 1 as follows: the column 1 is fixed on the two sides of the corresponding position of the crossbeam 2 and the connection angle 10 is fixed, and the crossbeam 2 is fixed on the connection angle. 10 on (see figure 2 ), which can be specifically: one side of the connecting corner code 10 is welded to a side of the column 1. The other side of the corner code 10 is connected with two connecting holes, which are connected with the beam 2 by bolts, thus forming the supporting frame required by the curtain wall.

[0014] The connecting piece includes a stone pallet 4, two fixing plates 5 and a cover plate 6. One end of the stone pallet 4 is a beam connecting end 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com